Aerospace CNC machining plays a pivotal role in the aviation and aerospace industry. It's the technology that enables the precision manufacturing of critical components. In this guide, I'll walk you through the importance, applications, key steps, material and process selection, quality standards, and the process of finding a reliable aerospace CNC machining service, with a special recommendation for Richconn's services.

Aerospace CNC machining is a fundamental part of aerospace manufacturing. Its significance lies in the ability to produce high-precision parts crucial for aviation and aerospace applications. This technology ensures that components meet stringent quality standards, contributing to the safety and performance of aircraft and spacecraft.

CNC machining's significance can be highlighted in the following table:

| Aspect | Significance |

|---|---|

| Precision Manufacturing | Ensures components meet tight tolerances, crucial for aerospace safety and performance. |

| Material Versatility | Allows machining of diverse materials, from aluminum to advanced composites. |

| Repeatable Accuracy | CNC machines provide consistent precision, reducing errors and rework. |

| Complex Geometry | Capable of producing intricate and complex parts needed in aerospace applications. |

| Enhanced Efficiency | Streamlines production processes, reducing time and costs while maintaining quality. |

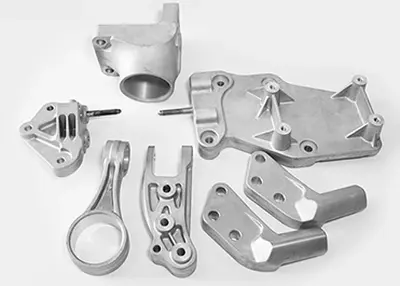

CNC machining finds applications in various aspects of aerospace, including the production of aircraft components, spacecraft parts, and more. These applications span from structural components like engine parts to intricate parts like turbine blades and landing gear components.

The following table illustrates some common aerospace components produced using CNC machining:

| Aerospace Component | CNC Machining Application |

|---|---|

| Aircraft Engine Parts | Precision machining of turbine blades, housings, and shafts. |

| Aircraft Structural Components | Production of wing ribs, spars, and landing gear components. |

| Satellite Components | Machining of satellite casings, solar panel frames, and antennas. |

| Avionics Housings | CNC machining used to create precise enclosures for avionics equipment. |

| Spacecraft Propulsion | Production of rocket nozzles, fuel injection systems, and thrusters. |

The process of aerospace CNC machining involves several critical steps:

CAD Design: It starts with Computer-Aided Design (CAD), where engineers create a digital blueprint of the part to be manufactured.

Process Planning: After design, process planning determines the best approach to manufacture the part, considering materials and tools.

Programming: CNC machines are programmed to follow the design and process instructions, translating the digital design into physical reality.

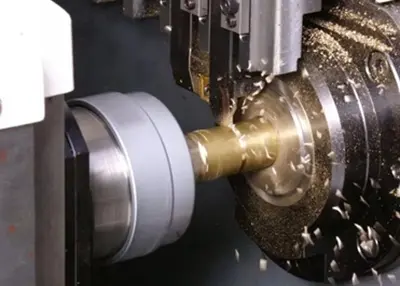

Machining Process: This step involves the actual CNC machining, where the machine accurately cuts, shapes, and drills the part according to the program.

These steps ensure precision and repeatability, crucial in aerospace component production.

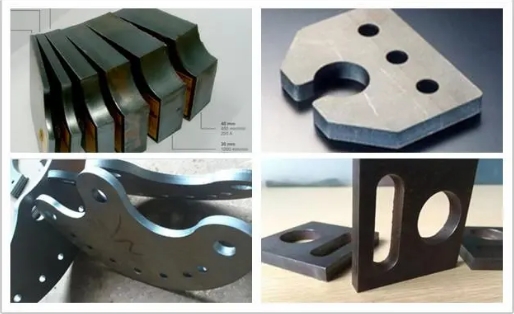

Material selection and process choices are paramount in aerospace CNC machining. Common materials include aluminum, titanium, and advanced composites. Material selection depends on factors such as strength, weight, and heat resistance. Additionally, the choice of machining processes, including milling, turning, and drilling, affects the final product's quality.

Aerospace material selection considerations are presented in the table below:

| Material Type | Characteristics | Common Aerospace Uses |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, good thermal conductivity. | Aircraft structural components, panels. |

| Titanium | High strength, corrosion resistance, low weight. | Engine components, landing gear. |

| Composites | Exceptional strength-to-weight ratio, corrosion resistance. | Fuselage components, wing structures. |

| Stainless Steel | High strength, corrosion resistance, heat resistance. | Fasteners, avionics housings. |

The choice of material is influenced by factors like the component's function, weight requirements, and the aerospace environment it will operate in.

Richconn's Expertise in Milling and Turning Services

When it comes to material selection and machining processes, Richconn excels in providing solutions tailored to the aerospace industry. They offer specialized milling and turning services that cater to the unique requirements of aerospace components:

Milling Services: Richconn's advanced milling capabilities allow for precision machining of complex aerospace parts. Their state-of-the-art 5-axis milling machines ensure the highest degree of accuracy and intricacy in part production.

Turning Services: Richconn's CNC turning services are designed to meet the needs of aerospace clients. They provide turning services for a wide range of materials, including aluminum, titanium, and stainless steel, delivering components with tight tolerances and exceptional surface finishes.

With Richconn's expertise in CNC milling services and turning services, you can trust them to handle your aerospace projects with precision and efficiency. Their commitment to quality and their advanced machinery make them a reliable partner for your material and process needs.

The choice of material and machining processes is crucial for achieving the highest standards in aerospace CNC machining. Richconn's specialized services ensure that your components are manufactured with the utmost precision and quality.

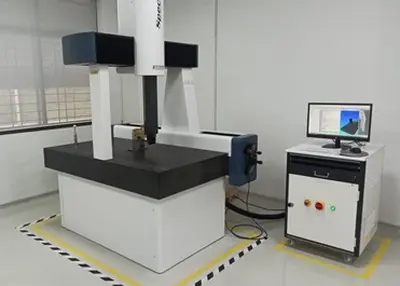

In aerospace CNC machining, maintaining impeccable quality and precision is non-negotiable. Components produced for aviation and aerospace applications must meet stringent standards to ensure safety and performance. These standards cover various aspects, including dimensions, tolerances, surface finish, and material properties.

Meeting Aerospace Quality Standards

Aerospace quality standards ensure that each component is fit for its intended purpose and operates safely in demanding environments. Some of the key aerospace quality standards include:

AS9100: The AS9100 standard is specific to the aerospace industry and sets rigorous quality management system requirements. It ensures product safety and reliability.

NADCAP: The National Aerospace and Defense Contractors Accreditation Program (NADCAP) covers specialized processes used in aerospace manufacturing. This program certifies compliance with industry standards in areas such as non-destructive testing, heat treatment, and more.

ISO 9001: While not exclusive to aerospace, ISO 9001 certification guarantees that the manufacturer follows stringent quality management practices.

Richconn is proud to adhere to and meet these quality standards in their aerospace CNC machining services. Their commitment to quality assurance processes and certifications ensures that the components they produce not only meet but often exceed the requirements for aerospace applications.

When it comes to aerospace CNC machining, finding a trusted precision machine shop is a critical step. Choosing a reliable company can significantly impact the quality and efficiency of your projects. Here are some key factors to consider when searching for the right aerospace CNC machining service:

Experience: Look for a provider with a wealth of experience in aerospace CNC machining. Years of experience often correlate with expertise in handling complex aerospace projects.

Technology and Equipment: Ensure that the service provider has state-of-the-art CNC machines and equipment. Advanced technology can greatly affect the precision and quality of the parts produced.

Quality Assurance: A commitment to rigorous quality control processes is essential. Ensure the provider follows industry-specific quality standards and conducts inspections and testing.

Timely Delivery: On-time project completion is vital in aerospace manufacturing. Check the provider's track record for meeting deadlines.

Cost-Effective Solutions: While quality is paramount, cost-effectiveness is also a factor. Compare pricing while considering the provider's reputation and the quality of their work.

Richconn, with its extensive experience and commitment to excellence, aligns with these criteria. They specialize in delivering precision aerospace components and have a reputation for timely delivery and cost-effective solutions.

In the aerospace CNC machining sector, Richconn is a name that stands out. With over two decades of experience, they specialize in delivering precision aerospace components. Richconn boasts advanced CNC technology, including 5-axis machining, ensuring the highest precision in part production.

Why Choose Richconn for Aerospace CNC Machining?

Richconn offers a host of advantages that make them an excellent choice for aerospace CNC machining services:

Experience: With more than 12 years of experience, Richconn has a deep understanding of the complexities of aerospace projects. Their seasoned team is well-equipped to handle intricate, high-precision parts.

Cutting-Edge Technology: Richconn has invested in state-of-the-art CNC machines, including 5-axis milling, which enables them to achieve the highest level of precision and intricacy in component production.

Quality Assurance: Richconn is committed to delivering components that meet and often exceed the rigorous standards of the aerospace industry. Their quality assurance processes are rigorous and systematic, ensuring that each part is of the highest quality.

Timely Delivery: In the aerospace industry, timely project completion is crucial. Richconn has a proven track record of delivering projects on time, helping clients meet their deadlines.

Cost-Effective Solutions: Richconn offers competitive pricing without compromising on quality. Their cost-effective solutions make them a reliable choice for aerospace projects.

Customization: Richconn works closely with clients to understand their unique requirements and provides tailored solutions. They excel in delivering precision components that meet specific project needs.

NADCAP Certification: Richconn holds NADCAP certification, demonstrating their expertise in specialized aerospace processes.

When it comes to aerospace CNC machining, Richconn is a name you can trust. Their combination of experience, advanced technology, and a commitment to quality and precision sets them apart in the industry.

The aerospace CNC machining is the backbone of the aviation and aerospace industry, ensuring the production of high-quality, precision components. Understanding its importance, applications, processes, and the selection of reliable service providers is crucial for aeronautical success.

What Are the Advantages of Cast Aluminum PartsOctober 19, 2023The continuous development of society, people's lives are increasingly high demand for aluminum casting process is also increasing in demand. In our use and use of aluminum casting process, do we understand the aluminum casting production out of aluminum die casting parts have what advantages?view

What Are the Advantages of Cast Aluminum PartsOctober 19, 2023The continuous development of society, people's lives are increasingly high demand for aluminum casting process is also increasing in demand. In our use and use of aluminum casting process, do we understand the aluminum casting production out of aluminum die casting parts have what advantages?view What Is Passivation and How to Passivate Stainless SteelSeptember 26, 2023Passivation is a technique used in cnc machining services for the surface treatment of metals to improve their corrosion resistance, extend their service life, and enhance their appearance.view

What Is Passivation and How to Passivate Stainless SteelSeptember 26, 2023Passivation is a technique used in cnc machining services for the surface treatment of metals to improve their corrosion resistance, extend their service life, and enhance their appearance.view Building Resilient Supply Chains: Five Ways to Increase ResilienceOctober 10, 2023As supply chains become more complex and the number of unforeseen disruptions increases, risk management strategies become critical for companies. Companies must be able to identify potential risks and vulnerabilities in their supply chains early and mitigate them before they become significant issues.view

Building Resilient Supply Chains: Five Ways to Increase ResilienceOctober 10, 2023As supply chains become more complex and the number of unforeseen disruptions increases, risk management strategies become critical for companies. Companies must be able to identify potential risks and vulnerabilities in their supply chains early and mitigate them before they become significant issues.view Analysis of Process Characteristics for CNC Machining PartsApril 4, 2023Choose the appropriate machine tool based on the material, contour shape, machining accuracy and other factors of the processed workpiece. Develop a machining plan, determine the processing sequence o...view

Analysis of Process Characteristics for CNC Machining PartsApril 4, 2023Choose the appropriate machine tool based on the material, contour shape, machining accuracy and other factors of the processed workpiece. Develop a machining plan, determine the processing sequence o...view What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view

What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view What Is a CMM Machine: Components, Uses, and BenefitsMarch 15, 2024Here is a thorough introduction to CMM machines from components, uses to benefits. Let’s have a deeper look and choose the best CMM service for your projects.view

What Is a CMM Machine: Components, Uses, and BenefitsMarch 15, 2024Here is a thorough introduction to CMM machines from components, uses to benefits. Let’s have a deeper look and choose the best CMM service for your projects.view

EN

EN

ru

ru