CNC machine tools (CNC machines) are highly automated manufacturing tools that use a computerized control system to precisely control the movement of tools and workpieces to perform a variety of machining operations.CNC manufacturing has been used in a wide variety of industries, from automotive to aerospace, and from medical devices to furniture manufacturing. Below are some examples of CNC manufacturing, demonstrating its wide range of applications in different fields:

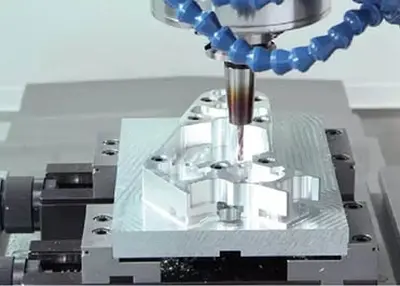

Milling machines: CNC milling machines are used to cut metal workpieces and manufacture various parts and components, such as automotive engine parts and airplane fuselage components.

Drilling Machine: CNC Drilling Machine is used for drilling and perforating metal workpieces, such as manufacturing ship structures, bridge components, etc.

Engraving machine: CNC engraving machine can be used for cutting, engraving and decorating metal workpieces, such as making jewelry and handicrafts.

CNC woodworking machine: CNC woodworking machine can be used for cutting, engraving, drilling wood workpieces, such as making furniture, wooden doors and windows, stairs, etc.

Injection Molding Machine: CNC controlled injection molding machine can be used to produce plastic products such as plastic containers, automotive parts, electronic equipment shells, etc.

CUTTING MACHINE: CNC cutting machine is used to cut and mold plastic sheets to make packaging materials, signs, labels, etc.

3D Printers: CNC-controlled 3D printers use layers of stacked material to create a variety of three-dimensional objects and are widely used in prototyping, medical device manufacturing, aerospace, and more.

Automotive manufacturing: CNC machine tools are used to create automotive engine parts, body components and interior parts.

Aerospace: CNC machine tools and 3D printing technology are used to manufacture airplane parts, rocket components and satellite components.

Electronics Manufacturing: CNC machines are used to manufacture circuit boards, semiconductors and other electronic components.

CNC machine tools are used to manufacture medical device parts such as prosthetics, artificial joints, and surgical tools.

CNC engraving machines are used in the production of artwork and decorative items, such as wood carving, stone carving, metal engraving, etc.

CNC Painting Robots: some artists use CNC painting robots to create paintings and sculptures.

CNC Waterjet Cutting Machine: used to cut construction materials such as marble, tile, glass, etc. to create decorative materials and building components.

CNC stage machinery: used to control the movement and transformation of stage elements, including stage sets, lighting and sound equipment.

CNC Textile Machines: used to weave, embroider, cut and sew fabrics to create apparel, home furnishings and fabric trim.

CNC Food Processing Machines: for cutting, carving and molding food products such as chocolates, candies and pastries.

CNC woodworking machines and laser cutters are used to produce furniture components such as chairs, tables, cabinets, etc.

CNC machines are used to produce toy parts and assemble toys such as model airplanes, robots, puzzles, and more.

These are just a few examples of CNC manufacturing applications; in fact, CNC technology can be used in almost any field that requires high precision and automated manufacturing. It not only improves productivity, but also reduces manufacturing errors, bringing higher quality and reliability to a variety of industries. As the technology continues to evolve, CNC manufacturing will continue to play an important role in driving innovation and progress in manufacturing on a global scale. For more information on advanced CNC machining services, including Shenzhen CNC machining, China 4 axis CNC machining, blackening surface treatment, and online CNC machining services China, visit Richconn's website.

CNC machining technology encompasses a wide variety of machining methods, including milling, turning, drilling, grinding, EDM, laser cutting, and more. These methods can be used to machine workpieces in a variety of different materials such as metals, plastics, wood, ceramics, etc. CNC machining is based on the principle that, according to pre-programmed commands, a computer controls the movements on the machine tool and the manipulation of the tools in order to accurately cut and form the workpieces to achieve the shapes and sizes required by the design.

High Accuracy: CNC machining is capable of achieving very high machining accuracy, often down to the sub-millimeter or even sub-micron level. This is important for the manufacture of workpieces and parts that require a high degree of precision, such as in the aerospace, medical device and automotive industries.

High productivity: CNC machining is faster and more consistent than traditional manual operations, which can greatly increase productivity. The automated machining process can run continuously without the need for intermediate stops, thus reducing production time.

Flexibility: CNC machining machines can be programmed to change to suit the requirements of different workpieces without having to change the entire machine setup. This flexibility allows the line to quickly adapt to the machining needs of different workpieces, reducing production downtime.

Machining of Complex Shapes: CNC machining can handle complex geometries including curves, surfaces and multi-axis motion. This makes it suitable for manufacturing workpieces that require complex shapes, such as turbine blades, parts and tooling molds.

Program control: CNC machining operates on the basis of pre-written programs, which means that the operator can change the machining process of a workpiece by modifying the program without having to change the machine settings. This makes the manufacturing process more controllable and adjustable.

Reduced Human Error: CNC machining reduces the risk of human error compared to traditional manual operations because it is computerized and independent of the operator's skill level.

Automation and monitoring: CNC systems are often equipped with automation features such as tool changing, workpiece clamping and quality monitoring. This helps reduce labor costs and increase productivity.

Data logging and analysis: CNC systems can log large amounts of machining data, which can help with quality control and process optimization. Operators can use this data to monitor the production process, identify potential problems and take corrective action.

Remote operability: Some CNC systems can be monitored and operated via remote access, which is useful for multinational manufacturing and remote technical support.

CNC machining technology represents a significant advancement in modern manufacturing and is used in a wide range of industrial applications. From small machine shops to large manufacturing plants, CNC machining plays a vital role. As computer technology continues to evolve, CNC machining systems are becoming more intelligent and advanced, capable of responding to increasingly complex machining needs.

At Richconn, our commitment to quality is unshakeable. We employ strict quality control standards to ensure that every product meets the highest quality standards. We believe that only exceptional quality can earn the trust and respect of our customers. Whether it's CNC machining service, sheet metal service, die casting service or 3D printing service, Richconn will provide you with reliable quality assurance.

CNC Machining Technology and ProcessJuly 27, 2023CNC Machining TechnologyCNC machining technology mainly includes CNC machine tool machining technology and CNC machine tool programming technology. CNC machine tool machining technology directly compl...view

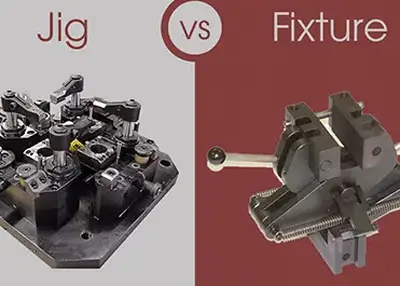

CNC Machining Technology and ProcessJuly 27, 2023CNC Machining TechnologyCNC machining technology mainly includes CNC machine tool machining technology and CNC machine tool programming technology. CNC machine tool machining technology directly compl...view Jig vs Fixture: Understanding the Differences and Applications of Two Common Workholding DevicesDecember 1, 2023Jig vs Fixture is a common topic in manufacturing and engineering. Jigs and fixtures are two types of devices that are used to hold, support, and locate workpieces during machining or assembly processes. However, they have some differences in their design, function, and application.view

Jig vs Fixture: Understanding the Differences and Applications of Two Common Workholding DevicesDecember 1, 2023Jig vs Fixture is a common topic in manufacturing and engineering. Jigs and fixtures are two types of devices that are used to hold, support, and locate workpieces during machining or assembly processes. However, they have some differences in their design, function, and application.view How to Define Insert? Understanding Its Process and Considerations (Explained)October 19, 2023Everyday objects that we use often involve different materials. For instance, scissors usually have plastic handles and metal blades. Although it may seem straightforward, engineers must carefully con...view

How to Define Insert? Understanding Its Process and Considerations (Explained)October 19, 2023Everyday objects that we use often involve different materials. For instance, scissors usually have plastic handles and metal blades. Although it may seem straightforward, engineers must carefully con...view What Is the Difference Between 304 Stainless Steel and 316 Stainless Steel?October 27, 2023It is alloyed from steel, chromium, nickel and other elements, where steel is the main component of stainless steel, while chromium is the main corrosion prevention element of stainless steel, and nickel helps to improve the corrosion resistance and strength of stainless steel.view

What Is the Difference Between 304 Stainless Steel and 316 Stainless Steel?October 27, 2023It is alloyed from steel, chromium, nickel and other elements, where steel is the main component of stainless steel, while chromium is the main corrosion prevention element of stainless steel, and nickel helps to improve the corrosion resistance and strength of stainless steel.view Metal CNC Machine: The Beginner’s Guide to Aluminum CNC MachineMarch 27, 2024Aluminum CNC machine is one of the most common types of metal CNC machines. Let’s have a look at its types, processes, applications and benefits.view

Metal CNC Machine: The Beginner’s Guide to Aluminum CNC MachineMarch 27, 2024Aluminum CNC machine is one of the most common types of metal CNC machines. Let’s have a look at its types, processes, applications and benefits.view 7 Types of CNC MachinesSeptember 13, 2023Here are the types of CNC machine. Read on to learn all you should know about this topic to help you select the best CNC machine type.view

7 Types of CNC MachinesSeptember 13, 2023Here are the types of CNC machine. Read on to learn all you should know about this topic to help you select the best CNC machine type.view

EN

EN

ru

ru