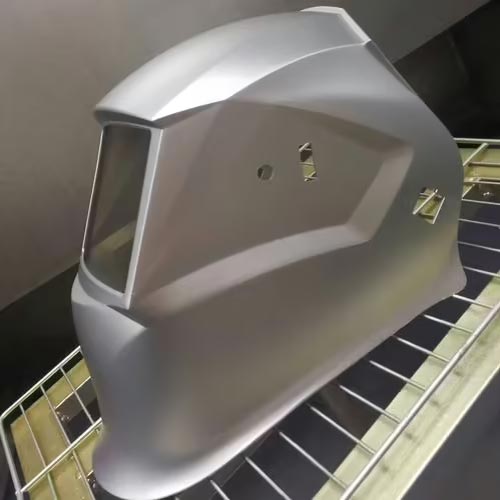

Waterborne aluminum powder coating on nylon+fiberglass composite materials is an ingenious technology that combines nylon and fiberglass to give a unique metallic appearance. This innovative coating technique is widely used to bring distinct visual effects to products across industries.

Waterborne aluminium powder coating on nylon+fiberglass composite materials is an amazing technology that ingeniously combines nylon and fibreglass to give a unique metallic appearance to the coating. This innovative CNC powder coating technique has been widely used in various industries, from automotive manufacturing to home decoration, bringing distinct textures and visual effects to products.

Waterborne aluminium powder coating on nylon+fiberglass composite materials is a coating technique that combines nylon and fibreglass materials and applies waterborne aluminium powder coating on their surface to create a metallic appearance. This technology combines strength, lightweight and aesthetics, making the material applicable in multiple fields.

Fiberglass composite materials have excellent mechanical properties such as high strength, rigidity and corrosion resistance. Combining them with materials like nylon can leverage the advantages of both materials to create more distinctive composite materials. In addition, these composite materials also have lower density, which helps reduce overall weight.

Waterborne aluminum powder coating gives the composite material a metallic texture, making it look like a real metal product. This coating is not only weather resistant but also effectively protects the material from erosion by the external environment, thereby extending the product's service life.

Ensure the surface is clean and dry, free of oils, contaminants or other substances that may affect adhesion. Wipe lightly with a small amount of acetone or alcohol to remove surface contaminants.

Select water-based epoxy or polyurethane primer suitable for fiberglass composite materials to increase adhesion. Spray a thin layer of primer to form a sealed paint film on the surface.

Polyester or acrylic surfacer can be used with water-based primer. Dilute the surfacer to spray viscosity and apply a thin layer to fill surface pores.

After the primer dries, the coating surface may need slight sanding for an even smoother texture. Bubbles, sagging or other issues during coating need to be repaired and smoothed out to ensure final coating quality.

Use water-based polyurethane or acrylic topcoat specially formulated for fiberglass composite materials. Ensure compatibility with primer and surfacer. Apply 2-3 layers of topcoat with 30-40μm wet film thickness per layer, bake at 140-160°C for 20-30mins between each layer.

If needed, a transparent water-based clear coat can be applied over the waterborne aluminum powder coating. This can further enhance the coating's protective properties, increasing its wear resistance and weather resistance, thus prolonging the service life of the coated surface.

Following the above steps creates an excellent coating with glossy appearance and water/corrosion resistance, increasing the service life of products made from the fiberglass composite material.

Waterborne aluminum powder coating on nylon+fiberglass composite materials has a wide range of applications. In automotive manufacturing, it can be used for car body coating to give cars a more futuristic look. In construction, this technology can be used for indoor and outdoor decoration to create unique metallic texture effects. It also has potential applications in home furnishings, marine vessels, electronics and more.

To maintain the appearance and durability of the coating, regular cleaning and maintenance is needed. Use mild detergents and soft cloths, avoiding corrosive substances. Periodically check for wear or damage to the coating and repair in a timely manner to prolong coating life.

A: Fiberglass composites offer high strength and lightweight properties, while the waterborne aluminum powder coating provides metallic texture and weather resistance. Combining both creates unique appearances and superior performance.

A: Waterborne aluminum powder coating has excellent weather resistance and can retain its color and avoid peeling for many years outdoors.

A: Applying this coating needs some professional skills and experience, especially during coating and curing. Seeking professional OEM precision CNC machining assistance is necessary.

A: As a waterborne paint, waterborne aluminum powder coating is more eco-friendly than traditional solvent-borne coatings, reducing pollution.

A: Avoid using corrosive cleaners on the coating to prevent damaging the surface. Use mild detergents and soft cloths for cleaning.

A: For food contact, the coating needs to meet certain safety standards. Seeking professional advice when selecting coatings is recommended.

Nylon+fiberglass composite materials have a range of unique properties that make them ideal choices across various fields. Not only do these materials have low density and high strength, but they also have good corrosion resistance and insulating properties. In industries like construction, automotive and aerospace, fiberglass composites have gained significant adoption. As a pro CNC China company, Richconn has complete material supply systems in Shenzhen, strong processing capabilities, and profound experience in surface treatment of fiberglass composites. For such needs, contact us.

What are the commonly used surface finishing?September 27, 2023Surface finishing is to clean, sweep, deburr, de-grease, de-oxidize, etc., the surface of the workpiece, which is used to meet the corrosion resistance, abrasion resistance, decorative or other special functional requirements of the product.view

What are the commonly used surface finishing?September 27, 2023Surface finishing is to clean, sweep, deburr, de-grease, de-oxidize, etc., the surface of the workpiece, which is used to meet the corrosion resistance, abrasion resistance, decorative or other special functional requirements of the product.view Top 12 CNC Machining Manufacturers in the USAJune 8, 2024Looking for reliable CNC machining parts manufacturers in the USA? Check out our list of the top 12 companies, each with its own unique advantages and processing capacities. Find the perfect partner for your business today!view

Top 12 CNC Machining Manufacturers in the USAJune 8, 2024Looking for reliable CNC machining parts manufacturers in the USA? Check out our list of the top 12 companies, each with its own unique advantages and processing capacities. Find the perfect partner for your business today!view Tips On How to Find Low Cost CNC Milling ServicesOctober 24, 2023CNC milling services are not cheap. The more accurate the design you need, the more money you can expect to spend. Reliable machine shops employ professional operators who use state-of-the-art equipment to fulfill orders. As a result, you can't afford to ignore your budget in order to shorten lead times or gain a competitive edge.view

Tips On How to Find Low Cost CNC Milling ServicesOctober 24, 2023CNC milling services are not cheap. The more accurate the design you need, the more money you can expect to spend. Reliable machine shops employ professional operators who use state-of-the-art equipment to fulfill orders. As a result, you can't afford to ignore your budget in order to shorten lead times or gain a competitive edge.view![Examining Alloy Definition and Alloying Examples [Basic Guide]](/uploads/image/20240226/14/basic-guide_400x400.webp) Examining Alloy Definition and Alloying Examples [Basic Guide]February 26, 2024Learn from alloy definitions and alloying examples, which can help you choose the best alloy for your project.view

Examining Alloy Definition and Alloying Examples [Basic Guide]February 26, 2024Learn from alloy definitions and alloying examples, which can help you choose the best alloy for your project.view Which Is Easier to Weld, Aluminum or Stainless Steel?October 26, 2023This is because the melting point of stainless steel is higher than that of aluminum alloys, which makes it more stable during the welding process. Aluminum alloys are prone to the risk of being burned through because of their low melting point during the welding process. In addition, aluminum alloys are also susceptible to the formation of an aluminum oxide film on the surface in air, which has a much higher melting point than aluminum itself, making it more difficult to weld.view

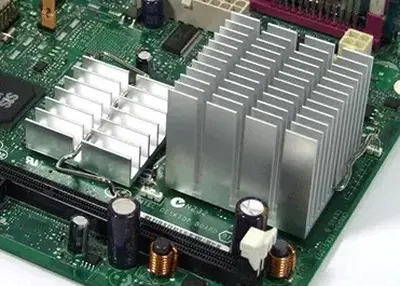

Which Is Easier to Weld, Aluminum or Stainless Steel?October 26, 2023This is because the melting point of stainless steel is higher than that of aluminum alloys, which makes it more stable during the welding process. Aluminum alloys are prone to the risk of being burned through because of their low melting point during the welding process. In addition, aluminum alloys are also susceptible to the formation of an aluminum oxide film on the surface in air, which has a much higher melting point than aluminum itself, making it more difficult to weld.view Heat Sinks: What They Are, How They Work, and How to Design ThemDecember 8, 2023Have you ever wondered how your laptop, smartphone, or gaming console can run so fast without overheating? The answer is heat sinks. Heat sinks are devices that help to cool down electronic components by transferring heat away from them. They are essential for ensuring the reliability and performance of many modern devices.view

Heat Sinks: What They Are, How They Work, and How to Design ThemDecember 8, 2023Have you ever wondered how your laptop, smartphone, or gaming console can run so fast without overheating? The answer is heat sinks. Heat sinks are devices that help to cool down electronic components by transferring heat away from them. They are essential for ensuring the reliability and performance of many modern devices.view

EN

EN

ru

ru