CNC machining services help you to manufacture and fabricate different parts of metal as per the requirements. This process also helps in creating tolerances for various materials and metal parts. This process is usually a subtractive method of producing metal parts.

This article will help you understand the process of CNC machining services. It will also explain how CNC mills and cutters work in this process. It will also describe the steps and methods involved in the process of creating metal parts through CNC machining services.

CNC machining is a process that helps in cutting different materials. The cutting of materials helps in creating metal parts of different sizes and shapes. Thus, the process actually removes the material from the metal surface in order to modify it.

The cutting process of CNC machining uses different types of cutting tools. There are different types and varieties of cutting tools available in the market. These help in cutting and trimming the metal to create different metal parts. All the processes are controlled by computers. Hence it is known as Computer Numerical Control (CNC) machining.

The process of CNC machining services involves certain steps. The first step in the process is to form the design of the part that we have to create. The formation of the design of the part is a function of CAD (Computer Aided Design) software. We can make the design that we require with the help of a computer for this software.

The next part of the process is to convert the design into physical form. This step of the process is the function of the CNC machine which recognizes the design of the part and converts it into physical appearance. The machine works according to the instructions we give it through the software.

The machine table contributes a lot in the creation of metal parts. The role of the machine table is to keep the material in place. The piece of material placed on the table is the workpiece. Therefore, the work table is vital for the efficient operation of the machine.

The table of a CNC machine has the ability to move in CNC machining services. However, the table may not move depending on the design of the machine and the type of process. Depending on the project, some machines have a moving table and some have a fixed table.

When the machine starts the cutting process, the table helps in bringing the cutting tool near the workpiece. As a result, the cutting tool comes close to the workpiece and starts cutting. Thus, the machine cuts the material in such a way that it cuts layers of material on its surface. The cutting process is carried out exactly as per the instructions of the computer.

The table of the machine or workpiece moves or rotates during the process. However, this rotation is carried out according to the G-code instructions of the software with the design of the metal part. In this way, the material layers are cut according to the design requirements of the software. This process continues until we get to the final part of the end product.

There are different types of CNC machines used in CNC machining services. the CNC machines include CNC milling machines, CNC Turning Machine, CNC routers, and Electro Discharge Machining (EDM) machines. Let us describe some of these CNC machines.

CNC mills are an important type of CNC machine. They have designated cutting tools. These tools are important in the cutting process of material parts. Moreover, these machines have the ability to rotate according to the design requirements of the metal CNC milling parts. Thus, they can cut the material at different angles and areas to make a perfect design.

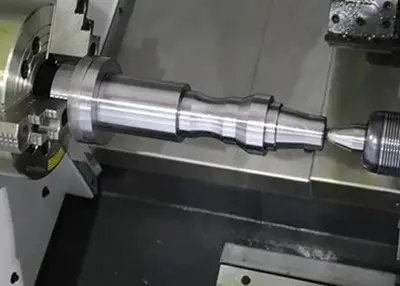

CNC turning machine have a different type of working as compared to CNC milling machines. These machines do not rotate on their own. But they rotate the work piece to perform different types of cutting actions. The cutting tools of these machines are stationary and do not move or rotate.

This way, the workpiece can be rotated and moved as needed, and the machining can be completed to get a fine piece of product.Precision CNC turning are especially important in the creation and manufacturing of cylindrical parts out of materials.

CNC router machines have similar jobs and functions as CNC milling machines. However, there is a difference between the two. The difference is that CNC routers cannot cut the hardest metals with ease. They are important in cutting soft materials. However, these machines are faster than CNC milling machines.

Electrical Discharge Machining (EDM) machines are CNC machines that do not use a tool in the cutting process. They use an electrical discharge or spark in the process to cut the material. However, there is no physical contact between the CNC machine and the material.

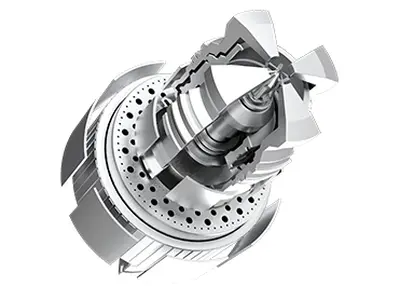

The specific characteristic of a CNC machine is the number of axes in the machine. The more axes the machine can move, the more complex designs it can generate. More axes help in creating complex and intricate metal parts.

CNC machining services are useful process to create different types of metal parts easily. We can generate any number or quantity of plastic and metal parts as per our requirement or need. Thus, this process helps us to mass produce the best and most efficient metal and plastic parts.

This machining service helps us to get rid of the high expenditure on the use of tools and hardware. Moreover, we can also save our budget by using expensive setups and tools. Moreover, the machining process helps in forming simple and complex designs equally.

We can use a wide range of materials in our CNC machining services. These include plastics, aluminum, titanium, brass, steel, metal alloys and other important materials. The type of material used depends on the nature of the metal part we have to manufacture.

Different projects and clients require different types of parts made from different materials. In this way, the materials we use in the machining process will also vary depending on the conditions.

CNC Machined Bottle Openers: Elevating Craftsmanship with Richconn PrecisionNovember 14, 2023Welcome to the realm where precision meets innovation – Richconn's CNC machined bottle openers redefine the art of craftsmanship. As a leading CNC machining service provider, Richconn is committed to delivering not just bottle openers, but a symphony of precision, design excellence, and user satisfaction.view

CNC Machined Bottle Openers: Elevating Craftsmanship with Richconn PrecisionNovember 14, 2023Welcome to the realm where precision meets innovation – Richconn's CNC machined bottle openers redefine the art of craftsmanship. As a leading CNC machining service provider, Richconn is committed to delivering not just bottle openers, but a symphony of precision, design excellence, and user satisfaction.view Different Types of Lathe Tools for CNC Lathe Machine and ApplicationsJanuary 10, 2024What are lathe tools? What are their essential components, types and classifications? Trust Richconn as your reliable partner for CNC machining solutions.view

Different Types of Lathe Tools for CNC Lathe Machine and ApplicationsJanuary 10, 2024What are lathe tools? What are their essential components, types and classifications? Trust Richconn as your reliable partner for CNC machining solutions.view Implant Abutment Materials and SelectionOctober 24, 2023Commonly used implant abutment materials can be divided into five categories: titanium (precision machining, polished, laser etched), surgical grade stainless steel, cast gold alloys, zirconium oxide, and polyether ether ketone (PEEK).view

Implant Abutment Materials and SelectionOctober 24, 2023Commonly used implant abutment materials can be divided into five categories: titanium (precision machining, polished, laser etched), surgical grade stainless steel, cast gold alloys, zirconium oxide, and polyether ether ketone (PEEK).view CNC Motion Control and Three Common TypesOctober 20, 2023Many CNC machines can be left unattended throughout the machining cycle, freeing the operator for other tasks. This benefit allows CNC users to provide several side effects, including reduced operator fatigue, errors due to operator error, and consistent and predictable machining times for each workpiece.view

CNC Motion Control and Three Common TypesOctober 20, 2023Many CNC machines can be left unattended throughout the machining cycle, freeing the operator for other tasks. This benefit allows CNC users to provide several side effects, including reduced operator fatigue, errors due to operator error, and consistent and predictable machining times for each workpiece.view 3-Axis Vs 4-Axis Vs 5-Axis CNCJuly 21, 20233-axis machiningThree axis CNC machining is the most basic, commonly used in the machinery manufacturing industry is one of the most important processing methods. Common understanding is: accurate lin...view

3-Axis Vs 4-Axis Vs 5-Axis CNCJuly 21, 20233-axis machiningThree axis CNC machining is the most basic, commonly used in the machinery manufacturing industry is one of the most important processing methods. Common understanding is: accurate lin...view Unlocking Precision: Exploring the Parts of a CNC MachineSeptember 22, 2023Are you ready to dive into the world of CNC (Computer Numerical Control) machines? If you're fascinated by precision engineering and the wonders it can achieve, you've come to the right place.view

Unlocking Precision: Exploring the Parts of a CNC MachineSeptember 22, 2023Are you ready to dive into the world of CNC (Computer Numerical Control) machines? If you're fascinated by precision engineering and the wonders it can achieve, you've come to the right place.view

EN

EN

ru

ru