The two technologies CNC machining and 3D printing have a major impact on many industries. But do they compete or complement each other?

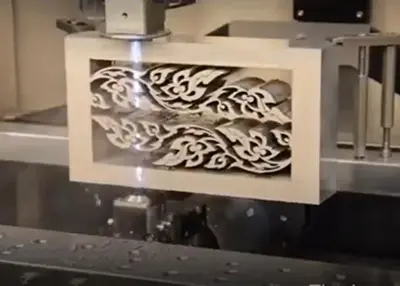

Simply put, CNC machining is the inverse of 3D printing. While 3D printing creates objects by building three-dimensional layers, CNC machining cuts into those objects. It's like the difference between making a sculpture out of clay (an additive process) and carving it out of marble (a subtractive process).

Of course, some pieces are best made by one process or the other. But in many cases, they work well together. A good example of this is "finishing" a 3D-printed object using CNC machining to enhance the surface or add holes, grooves or threads.

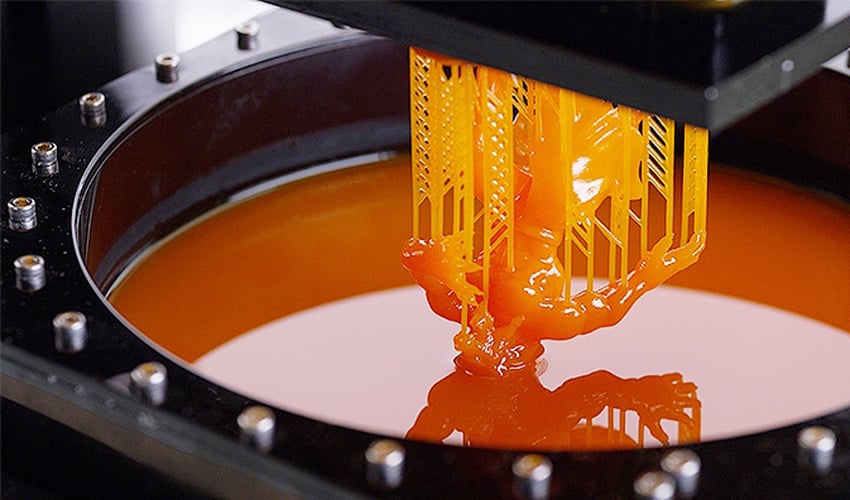

When is it advisable to separate the two processes? In what ways is one better than the other? If you've ever resorted to 3D printing, you'll know that the process is particularly well-suited for very specialized designs. Since it starts from scratch and adds layer after layer, there are almost no limits to the results. The only limitation is in the capabilities of the printer. It is also a flexible process, so you can quickly switch back and forth between different jobs. The unit cost of a given object is always the same, regardless of the quantity. Thus, 3D printing is ideal for the production of individual, even unique objects. It's no wonder that the process is used in many medical and dental applications, where it can be used to customize objects for individual patients.

But this great strength can also prove to be a weakness: For some mass production applications, 3D printing can be uneconomical. In addition, the output size is limited. While the process is perfect for small, intricate objects, the maximum size is close to the size of a washing machine (stereolithography with certain materials).

In such cases, CNC machining sometimes gets the job done. This can efficiently produce significant quantities of Precision Machining products from a variety of materials. Parts for commercial and industrial applications and machinery are particularly popular, especially those made from high-density metals. The process is also suitable for smaller batch quantities, although unit costs are then typically higher.

The decision between 3D printing and CNC machining thus often depends on the size of the production run and the output size. However, if these factors are neither too large nor too small to rule out either process, the techniques can be effectively combined.

This combined approach should be urgently explored and developed. As manufacturers need to meet the increasing demands of their customers, technology must evolve to keep pace. This involves producing higher-performing products and services faster and more efficiently. That's why the combination of 3D printing and CNC machining can bring significant benefits.

In particular, the two technologies together can help address the major design challenges facing manufacturers today - especially with regard to the demand for lighter components and products, as well as objects with increasingly complex geometries. This is where 3D printing, in combination with CNC machining, can achieve more than any other process. The flexibility of 3d printing service is enhanced by the precision of CNC machining, enabling the production of even more complicated objects.

And because CNC machining can provide the finishing touches needed to complement 3D printing, it doesn't have to be limited to larger production runs. Richconn has the equipment for both 3D printing and CNC machining. As a result, we often combine the two technologies to produce prototypes and models, or for mid-size runs needed for performance testing. This dual approach is also ideal for producing replacement parts for obsolete products.

The trick is to recognize the specific value of each technique and apply it in the most appropriate way to the design and production processes. At each point in the prototyping, testing and manufacturing cycle, 3D printing and CNC machining services can be used either individually or together. By working with a provider where both technologies are under one roof, you can move more flexibly between the two. The result? You make the most of both processes to meet the demands of today's rapidly changing markets.

Unveiling the Wonders of Electrophoresis Metal Coating in Gel ElectrophoresisFebruary 29, 2024Gel electrophoresis, a foundational technique in the field of molecular biology, serves as a crucial tool for scientists to unravel the complexities of genetic material. At the heart of this precision...view

Unveiling the Wonders of Electrophoresis Metal Coating in Gel ElectrophoresisFebruary 29, 2024Gel electrophoresis, a foundational technique in the field of molecular biology, serves as a crucial tool for scientists to unravel the complexities of genetic material. At the heart of this precision...view CNC Turning Process And Process AnalysisJune 21, 20221. The content of CNC turning processThe CNC turning process is the sum of the methods and technical means used when CNC lathes are used to process parts. Its main contents include the following aspec...view

CNC Turning Process And Process AnalysisJune 21, 20221. The content of CNC turning processThe CNC turning process is the sum of the methods and technical means used when CNC lathes are used to process parts. Its main contents include the following aspec...view What Are the Categories of Fastener Nuts?October 30, 2023Some parts manufactured in the automotive industry can only function if they are connected to other parts during the assembly process. As a result, automotive parts manufacturing relies on designs that have high tolerances and incorporate connecting mechanism features, of which fasteners are very common.view

What Are the Categories of Fastener Nuts?October 30, 2023Some parts manufactured in the automotive industry can only function if they are connected to other parts during the assembly process. As a result, automotive parts manufacturing relies on designs that have high tolerances and incorporate connecting mechanism features, of which fasteners are very common.view What Products Can Be Customized with a Five Axis CNC Machining Center?August 14, 2023A five-axis machining center is a highly technological, high-precision machine tool specialized in processing complex surfaces, and has a crucial influence on industries such as national aerospace, mi...view

What Products Can Be Customized with a Five Axis CNC Machining Center?August 14, 2023A five-axis machining center is a highly technological, high-precision machine tool specialized in processing complex surfaces, and has a crucial influence on industries such as national aerospace, mi...view CNC Cutting Aluminum Sheets for Electronics EnclosuresFebruary 29, 2024Elevating Electronics Enclosures with CNC PrecisionIn today's fast-paced technological landscape, where precision and efficiency are critical, the manufacturing of electronics enclosures demands i...view

CNC Cutting Aluminum Sheets for Electronics EnclosuresFebruary 29, 2024Elevating Electronics Enclosures with CNC PrecisionIn today's fast-paced technological landscape, where precision and efficiency are critical, the manufacturing of electronics enclosures demands i...view Titanium vs Steel: Is Titanium Stronger Than Steel?August 29, 2023Is titanium stronger than steel? Here's a brief guide that compares steel to titanium from different aspects.view

Titanium vs Steel: Is Titanium Stronger Than Steel?August 29, 2023Is titanium stronger than steel? Here's a brief guide that compares steel to titanium from different aspects.view

EN

EN

ru

ru