With the improvement of people's living standards, the luxury market is booming. Many luxury goods use specialized high-tech materials in their design and manufacturing processes to ensure that their quality is different. Carbon fiber is a specialized material widely used in the luxury sector. Among them, NTPTTMultra-high-performance prepreg carbon fiber has become one of the carbon fiber materials chosen by luxury manufacturers because of its excellent material properties. This article will comprehensively analyze the excellent characteristics of NTPTTM ultra-high-performance prepreg carbon fiber and its application in the luxury field.

Carbon fiber form.

Carbon fiber sheet, carbon fiber plate, carbon fiber tube, chopped carbon fiber, prepreg carbon fiber, etc.

Carbon fiber products

Carbon fiber fabric, carbon fiber weaving, carbon fiber cloth, carbon fiber tape, honeycomb carbon fiber, etc.

Carbon fiber composites.

Carbon fiber reinforced polymer (CFRP), carbon fiber reinforced concrete, carbon fiber reinforced silicon carbide (C/SiC), etc.

Carbon fiber applications

Drones, automobiles, aerospace, sports equipment, golf, watches, ships, etc.

Other

Carbon fiber price, carbon fiber color (white, blue, yellow, etc.), carbon fiber manufacturing process, etc.

Here I briefly summarize several common preparation processes of ordinary carbon fiber:

Craft | Illustrate |

PAN precursor method | 1. Spun polyacrylonitrile (PAN) solution into PAN precursor yarn 2. Heat treatment to orient PAN molecules 3. Carbonization and surface treatment in an inert atmosphere |

Vapor deposition method | 1. Use carbon source gases such as methane and propane 2. Carbon fibers are grown under the action of transition metal catalysts |

Liquid phase deposition method | 1. Dissolve PAN or sugars in organic solvents 2. Spraying on the substrate for pyrolysis 3. Generate directionally grown carbon fibers |

Grafting self-assembly method | 1. Grow short carbon tubes in gas or liquid phase deposition 2. Grafting and self-assembly generate continuous carbon fiber |

Precursor transformation | 1. Use fine PAN or lignin fibers as precursors 2. Heat treatment to convert resin into carbon |

Here is a tabular summary of the common carbon fiber products, characteristics and approximate prices of several brands:

Brand | Model | Intensity level | Peculiarity | Price(RMB/ton) |

Toray | T300 | General intensity | Higher stiffness | 75,000-85,000 |

T700 | Medium to high strength | Cost-effective | 95,000-120,000 | |

T800 | Strength | Excellent strength and stiffness | 130,000-150,000 | |

T1000 | Ultra-high strength | The intensity is extremely high | 160,000-200,000 | |

Celanese | Celion | Medium intensity | Good toughness | 80,000-100,000 |

G40-800 | Strength | High modulus of elasticity | 120,000-140,000 | |

Huzhou Oriental Carbon | GRANOC | General intensity | Price advantage | 65,000-80,000 |

GRANOC YS | Strength | Strength | 100,000-120,000 | |

Toray TCAC | T300 | General intensity | Cost-effective | 70,000-90,000 |

T700GC | Medium to high strength | The intensity is more balanced | 100,000-120,000 | |

T800GC | Strength | High modulus of elasticity | 130,000-150,000 | |

Zhongfu Shenying | CF0300 | General intensity | Affordable | 65,000-80,000 |

CF0700 | Medium to high strength | Good value for money | 90,000-110,000 | |

CF0800 | Strength | Higher intensity | 120,000-140,000 |

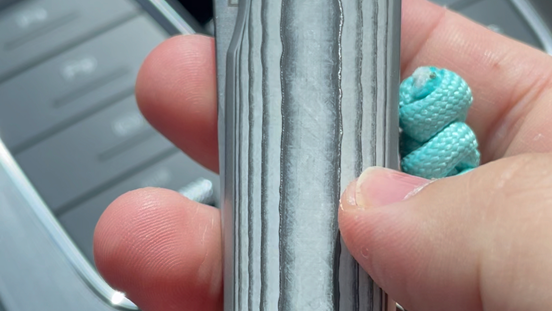

NTPT stands for Thin Ply Technology, which means thin layer technology, and is a French company of control technology (Toray Composites France S. A.) A carbon fiber reinforced composite material developed in the 90s. By reprocessing traditional carbon fibers, the thickness of the unidirectional thin layer is greatly reduced, and the unidirectional layer thickness of NTPT carbon fiber can reach 0.03mm, which is 1/10 of ordinary carbon fiber. The ultra-fine thin layer thickness reduces the anisotropy of NTPT carbon fiber, resulting in more uniform performance.

After more than 20 years of development, NTPT carbon fiber has now become a high-end carbon fiber brand with excellent performance, which is widely used in racing cars, aircraft, yachts, watches and other fields with extremely high requirements for strength and rigidity. It has also been selected as a special material by many luxury brands due to its unique properties, and is used in the manufacture of luxury goods such as limited edition sports cars and luxury yachts.

The manufacturing process of NTPT carbon fiber is very complex and requires precise control of all links:

PAN (polyacrylonitrile) was selected as a precursor raw material, and ultrafine PAN precursor fibers were prepared by solution spinning.

PAN fibers are subjected to high-temperature oxidation, carbonization and surface treatment to form fine carbon fibers with a high degree of warp orientation.

Fine carbon fibers and epoxy resins are pre-impregnated to precisely control the resin content.

The prepreg is made into an ultra-fine unidirectional thin layer of about 0.03mm through a patented process.

Ultra-fine unidirectional thin layers are stacked through automated equipment for design-oriented layers.

Carbon fiber composite sheet is made by vacuum hot pressing process.

CNC cutting of plates to obtain composite parts of the desired shape.

Finally, the curing process is carried out to complete the manufacturing of ultra-high-performance NTPT carbon fiber composite materials.

Compared with ordinary carbon fiber, the core innovation of NTPT carbon fiber lies in the preparation of ultra-fine unidirectional layers, which greatly improves the anisotropy and mechanical properties of the material. This patented process makes it a high-end carbon fiber material.

Compared with ordinary carbon fiber, NTPT carbon fiber has obvious advantages in strength, stiffness, compression resistance, fatigue resistance and other aspects. Here's a specific analysis of its outstanding features:

The single layer thickness of NTPT carbon fiber can be refined to 0.03mm, which is 1/10 of the thickness of ordinary carbon fiber single layer 0.25mm. The fine layer thickness greatly reduces the anisotropy of NTPT carbon fiber and makes the mechanical properties of the material uniform in all directions. This provides great flexibility in the design of composite materials.

The tensile strength of NTPT carbon fiber can reach 4900MPa, and the tensile modulus can reach 285GPa, which is twice that of ordinary carbon fiber. This means that NTPT carbon fiber has extremely high strength and stiffness, which can provide greater rigid support while maintaining a lighter weight.

Under high-pressure loads, NTPT carbon fiber has little loss of strength. This makes it ideal for applications where pressure resistance is extremely demanding, such as deep-sea submarines, high-altitude aircraft, etc.

NTPT carbon fiber has little loss of fatigue strength after being subjected to dynamic vibration loads. This means that its fatigue life is very long and can withstand long cyclic loads. This makes it particularly suitable for luxury goods such as racing cars that require long-lasting fatigue resistance.

The elongation at break of NTPT carbon fiber reaches 1.8%, showing excellent toughness. This makes it less prone to brittle failure and guarantees structural integrity even in complex stress environments.

The fine unidirectional layer thickness minimizes the anisotropy of NTPT carbon fiber, which greatly improves the construction flexibility of the material. Users can design various orientations according to their needs, without being limited by the anisotropy of ordinary carbon fibers.

NTPT carbon fiber enables high-fidelity performance conversion with minimal performance loss from prepreg to final product. Users can take full advantage of the excellent properties of the prepreg.

In summary, NTPT carbon fiber far surpasses ordinary carbon fiber in terms of strength, stiffness, compression resistance, fatigue resistance, toughness and other aspects, and is a real high-performance carbon fiber. The fine unidirectional layer thickness also provides great build flexibility. It is these outstanding properties that make NTPT carbon fiber the first-class carbon fiber material of choice for luxury brands.

NTPT carbon fiber, as a new high-performance material, although the overall performance is excellent, but also has some disadvantages:

1. High price

The manufacturing process of NTPT carbon fiber is complex, the raw materials are expensive, and the current production is limited, and its price can be as high as 3 million US dollars per ton, which is 10-100 times that of general carbon fiber, making it only suitable for low-volume luxury production.

2. It is difficult to process

NTPT carbon fiber is extremely hard and brittle, not easy to cut and manufacture, extremely high requirements for processing equipment, and poor machinability. This increases the difficulty of production and processing.

3. The interface bonding force is weak

The interface adhesion between NTPT carbon fiber and materials such as resin is not as good as that of general carbon fiber, which is not conducive to the production of composite materials. Surface treatment is required to improve adhesion.

4. The manufacturing process is complicated

NTPT carbon fiber manufacturing process is complex, equipment investment is large, only a very small number of companies master key technologies, resulting in very limited global production capacity.

5. Low repeatability

The performance parameters of each batch of NTPT fiber will have certain variation, and the repeatability is not as good as that of other mature types of carbon fiber.

6. Insufficient long-term performance data

As a new material, the performance data of NTPT carbon fiber after long-term use still needs to be accumulated. Its long-term stability remains to be seen.

7. Difficulty in recycling

NTPT carbon fiber is not easy to recycle, which also limits its large-scale application.

In general, NTPT carbon fiber as a new high-performance fiber material, its production and application still has a lot of room for improvement. With the further maturity of related technologies, it is expected to overcome these shortcomings and achieve wider commercial applications.

Due to its excellent mechanical properties, NTPT carbon fiber is often used in luxury goods with extremely high material requirements, mainly in two major fields:

NTPT carbon fiber is widely used in the body structure material of ruthless F1 cars and other top race cars. Its thinness and lightness reduce mass, and excellent strength, stiffness and fatigue resistance are essential to ensure the safety of the car. Many first-tier F1 teams are using NTPT carbon fiber in large quantities.

In addition, the limited edition supercar also chose NTPT carbon fiber. For example, models such as Pagani Huayra use NTPT carbon fiber reinforced titanium alloy materials, which reduce the quality of the vehicle and improve strength and rigidity. These supercars are also more collectible due to the use of this professional-grade carbon fiber material.

Many high-end yachts also choose NTPT carbon fiber as the hull construction material. Its excellent specific strength and specific stiffness help create a lighter and stronger hull and increase sailing speed. Some luxury yacht brands such as Wally have widely used NTPT carbon fiber on their limited edition yachts.

Many top Swiss watch brands such as Richard Mille, TAG Heuer, Vacheron Constantin, etc., apply NTPT carbon fiber to the case of flagship series or zone watches. This not only has a visual highlight, but also significantly improves the lightweight and impact resistance of the case. In particular, Richard Mille's full range uses NTPT carbon fiber material as the base material for the middle frame, panel and back plate of the fuselage, creating an unparalleled luxury price.

NTPT carbon fiber has low anisotropy, which can produce complex three-dimensional glasses frames and achieve unique styling designs. NTPT carbon fiber frame is used on sports glasses with high strength requirements such as ski goggles and cycling goggles to ensure that they can provide ultra-high impact resistance in sports. At the same time, it provides good heat dissipation performance and avoids the discomfort caused by wearing glasses for a long time.

NTPT carbon fiber materials are also widely used in electronic products such as mobile phone cases, tablet computer shells, drone racks, camera bodies, high-end audio and other products. These are the elements of customizable texture, strong material properties and high-end quality. Let it be used in a lot in all aspects of our lives.

NTPT carbon fiber composite consists of two parts: prepreg and curing process. The following is a brief explanation of its manufacturing process:

Prepreg preparation

The high-strength and high-modulus PAN series resistant carbon fiber was selected for meticulous prepreg process design. High-quality epoxy resin is selected for thermosetting prepreg, and parameters such as volume content are carefully controlled to obtain carbon fiber prepreg with excellent performance.

Directional arrangement

Through the automation equipment, the slender NTPT prepreg is precisely arranged at the angle of design requirements, and the orientation of each layer of prepreg is controlled to reduce the misalignment between layers.

Vacuum bag forming

The arranged prepreg is tightly formed by vacuum bag technology, and the temperature is raised with a hot pressing plate to pre-solidify the resin in the prepreg.

Automatic cropping

The formed "part" is automatically cut by a CNC CUTTING machine to obtain the desired shape of carbon fiber composite parts.

Curing

The cut parts are cured using an automatic curing oven, and the curing temperature and time are strictly controlled according to the curing curve of the resin to obtain an NTPT carbon fiber composite final product with excellent performance.

It is foreseeable that NTPT carbon fiber composite materials will be used in more fields in the future.

Due to its extremely high specific strength and specific stiffness, NTPT carbon fiber will be used in more aerospace equipment, helping to continue to reduce weight and improve performance.

Electric vehicles have a huge demand for lightweight bodies, and the high strength, high rigidity and lightweight performance provided by NTPT carbon fiber will become an effective means of lightweight electric vehicles.

High-end consumer electronics such as mobile phones and laptops also need to be lightweight, and NTPT carbon fiber composite materials will provide structural material options.

Industrial fields such as construction machinery and wind power blades with high requirements for load and fatigue performance require excellent carbon fiber materials, and NTPT carbon fiber will also play a greater role.

The use of 3D printing technology for the additive manufacturing of carbon fiber is a hot spot in research and development. The elongated and low anisotropy nature of NTPT carbon fiber helps to print better carbon fiber structures.

In summary, NTPT carbon fiber, as a high-end carbon fiber brand with excellent performance, has been widely used in luxury manufacturing. Its extremely high mechanical properties will allow it to play a greater role in more high-performance fields. NTPT carbon fiber will continue to provide ultra-high-performance material solutions for various industries.

Q: What is carbon fiber?

A: Carbon fiber is a carbon element-based fiber material with excellent properties such as high strength, high modulus, high heat resistance and low density.

Q: What is the raw material of carbon fiber?

A: PAN (polyacrylonitrile) is the most commonly used precursor raw material for carbon fiber, and natural polymers such as viscose and lignin are also used as precursors.

Q: What is the manufacturing process of carbon fiber?

Answer: There are mainly PAN prefilament method, vapor deposition method, liquid deposition method, etc., and PAN prefilament method is the most widely used.

Q: What are the uses of carbon fiber?

A: Carbon fiber is widely used in aerospace, automotive, sporting goods, wind power blades and other fields.

Q: What is the difference between carbon fiber and glass fiber?

A: Compared with glass fiber, carbon fiber has higher specific strength and specific stiffness, lighter, but more expensive.

Q: What is prepreg carbon fiber?

A: The carbon fiber and resin are pre-impregnated to stabilize and facilitate the subsequent manufacture of semi-finished carbon fiber.

Q: What are carbon fiber composites?

A: Carbon fiber reinforced plastics (CFRP), carbon fiber reinforced concrete, carbon/carbon composites, etc.

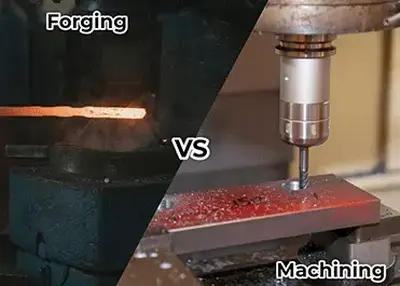

Forged vs. Machined: Unveiling the Essence of Manufacturing ExcellenceNovember 15, 2023In the ever-evolving landscape of manufacturing, the decision between forging and machining becomes the linchpin determining the quality, efficiency, and cost-effectiveness of the end product. Navigating the complexities of these two processes requires a nuanced understanding of their intricacies, advantages, and applications.view

Forged vs. Machined: Unveiling the Essence of Manufacturing ExcellenceNovember 15, 2023In the ever-evolving landscape of manufacturing, the decision between forging and machining becomes the linchpin determining the quality, efficiency, and cost-effectiveness of the end product. Navigating the complexities of these two processes requires a nuanced understanding of their intricacies, advantages, and applications.view The Functional Advantages of Custom PVD Coating in Automotive DesignJanuary 5, 2024When it comes to automotive design, every detail matters. From the sleek lines of the exterior to the carefully crafted interior, each element plays a crucial role in creating a unique and memorable d...view

The Functional Advantages of Custom PVD Coating in Automotive DesignJanuary 5, 2024When it comes to automotive design, every detail matters. From the sleek lines of the exterior to the carefully crafted interior, each element plays a crucial role in creating a unique and memorable d...view Analysis of the Advantages and Characteristics of 4-axis Machining Center ProcessingOctober 24, 2022At present, there are many methods and equipment used in machining centers, among which CNC four-axis machining centers are a more common machining method. Initially, three-axis machining was generall...view

Analysis of the Advantages and Characteristics of 4-axis Machining Center ProcessingOctober 24, 2022At present, there are many methods and equipment used in machining centers, among which CNC four-axis machining centers are a more common machining method. Initially, three-axis machining was generall...view What is a shaft in manufacturing? Detailed Process and TypesMay 4, 2024Explore the detailed process of shaft machining, its types, and surface finish choice. Discover challenges where shaft machining could be avoided.view

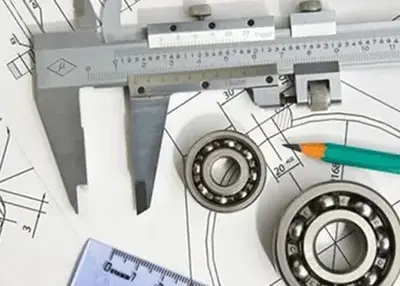

What is a shaft in manufacturing? Detailed Process and TypesMay 4, 2024Explore the detailed process of shaft machining, its types, and surface finish choice. Discover challenges where shaft machining could be avoided.view Fundamentals and Techniques of Engineering DrawingsDecember 1, 2023Engineering drawings are a graphical language used to express engineering design ideas and details, and they are an important tool for engineers for design, manufacturing and maintenance. Engineering drawings follow a number of international or national standards and specifications to ensure the accuracy, consistency and readability of engineering drawings.view

Fundamentals and Techniques of Engineering DrawingsDecember 1, 2023Engineering drawings are a graphical language used to express engineering design ideas and details, and they are an important tool for engineers for design, manufacturing and maintenance. Engineering drawings follow a number of international or national standards and specifications to ensure the accuracy, consistency and readability of engineering drawings.view The Science of Black: Understanding the Chemistry Behind Surface TreatmentsDecember 4, 2023Black as a color has always captivated and fascinated humans. It is mysterious, elegant, and striking, making it a popular choice for various applications. From fashion and design to technology and en...view

The Science of Black: Understanding the Chemistry Behind Surface TreatmentsDecember 4, 2023Black as a color has always captivated and fascinated humans. It is mysterious, elegant, and striking, making it a popular choice for various applications. From fashion and design to technology and en...view