Not so long ago, prototyping and low-volume parts manufacturing was a fairly costly and time-consuming process. You sent a paper drawing to the precision machine shop of your choice, briefly discussed the delivery date and price with the owner or shop manager, and waited. If it had to be done quickly, one paid overtime to get the parts sooner, but prototyping was still a test of patience. You got real parts, but at the cost of valuable production time and money.

Then came the service companies with their 3D printers. Plastic prototypes could now be ordered quickly and far more cheaply than from the local machine shop, which had to set up a machine first. The only problem was materials - those early stereolithography (SL) systems were limited to one or two types of liquid photopolymers, suitable only for display objects or as patterns for printing and injection molding.

Additive manufacturing was still in its infancy. Soon, other methods with confusing acronyms became available. One of these is selective laser sintering (SLS), which uses a powder bed of a polyamide-based material instead of molten plastic. Support structures, as with SL, are not required here, resulting in less post-processing, saving time and money.

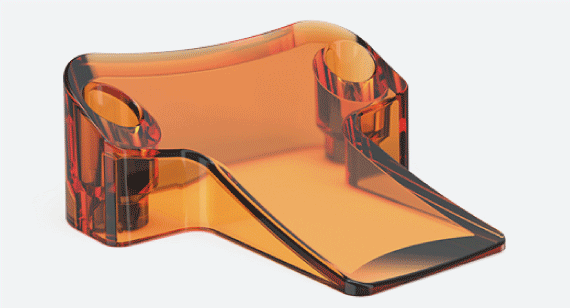

Stereolithography has not rested on its laurels in the meantime. SL parts are now made from a range of plastics that have some of the properties of engineering plastics. These are available in a variety of colors and strengths, making them suitable for more than just presentation purposes.

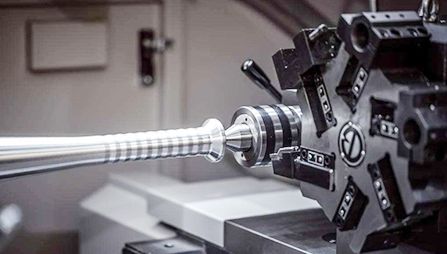

Machining has also evolved over the years. For example, Richconn' CNC machining service is able to deliver machined plastic and metal parts in less time than it takes traditional machine shops to quote. Upload a CAD file, select the material and quantity, and let us know when you need the parts. Chances are you can get the parts by the next day, at a cost comparable to 3D printing and even lower for certain geometries.

As with buying a smartphone, the problem today is the wide selection. How does a product designer or engineer know which process is best for their part design? Let's start with machining, which has been around at least a century longer than additive manufacturing.

In general, plastic is very easy to cut. Granted, fiberglass-reinforced materials are somewhat difficult to cut for end mills, and acrylics can break. Teflon is smoother than a politician. But in essence, machining plastic is as easy as it seems.

Richconn is capable of machining more than three dozen types of engineering thermoplastics. Some of these are also available with Richconn' additive processes, but in terms of material selection and quality, machining clearly wins. Acrylic, acetal, ABS, nylon, PC, PP, PEI and PEEK - these and a range of other plastics cover the needs of almost any part design imaginable. Finished plastic parts can be used for mold and fit testing and, in many cases, even as functional parts.

Material options are more limited for additive processes using plastic. SL parts are built from photopolymers that have some of the properties of plastics, such as ABS, PC and PP. They work well for prototypes to verify shape and fit, but for functional parts, machining should be chosen if the design allows. It's a slightly different story with SLS, which uses true thermoplastic polyamides for part construction. This process typically gives 3D-printed parts greater durability and rigidity, but color options are literally limited to black and white, and surface finishes are not nearly as high quality as machined parts.

When it comes to part geometry, the machining process sometimes comes off poorly. Richconn uses 3-axis CNC machining centers. These produce mostly orthogonal parts: an engine mount, a camera housing, the base plate for a thermostat, or even the thermostat housing itself - these are consistently well suited for machining.

Sharp inside edges on vertical walls present a challenge, as do undercuts more than a few inches deep. Almost everything else, however, is a breeze. Richconn plans to introduce a CNC turning service for plastics during 2015 as a counterpart to our current CNC turning process for metals. Until then, cylindrical plastic parts - a drive shaft for a snowmobile or a trailer hitch - can still be made by machining (or 3D printing).

And then there are part designs where machining fails. This is where additive processes enter the picture. For example, it would be impossible to machine a punched ball - an easy game for SL and SLS, on the other hand. Machining the internal cooling channels of a heat exchanger would also be a challenge, but entirely possible with additive manufacturing.

For other parts, the outcome is completely open. A signet ring can be machined or printed, but it would be wasteful and time-consuming to mill the material out of the ring. The same is true for a picture frame or a napkin holder set. The additive process is ahead of the game here because it is able to print only the material that is actually needed.

Another important consideration that should be taken into account when considering geometry is whether the part can ultimately be produced in larger quantities in a manufacturing process, such as injection molding. Typically, a machined part can be more easily injection molded than an additive part for two reasons: the material used in machining can be more easily duplicated in injection molding, and 3D-printed parts with highly complicated geometries are very likely to require modification to be effectively injection molded.

In addition to material selection, there are other important differences between machining plastics and additive processes. In terms of accuracy and surface quality, machining tends to be more accurate and have better long-term dimensional stability than SL parts, while surface qualities between the two processes are roughly comparable. SLS parts have rougher surface finishes than SL or machined parts, are stronger than SL parts, and are about as dimensionally stable as machined nylon parts.

Rapid injection molding stands out when comparing additive processes and plastics machining. Although injection molding at Richconn is often used for low-volume production, most customers also use the service to produce small quantities of prototypes and production parts with similar processing times as with additive processes and machining. If this is the case, various design considerations play a role, for example, in the areas of material selection, geometry and tolerances mentioned above. However, that may be a topic for a future design tip.

With small quantities of plastic parts, there is a lot to consider. Once you have a design, it's best to upload it to richconn-cnc.com and request an interactive quote for the various manufacturing options to compare in terms of price, machining time and material selection. If you still have questions, please refer to our full range of materials, or simply call our technical support staff at +86-0755-28025755.

Unlocking Precision: The Definitive Guide to Machined Surface Finish in CNC MachiningNovember 10, 2023Welcome to the realm of precision engineering, where the art of CNC machining meets the science of Machined Surface Finish. In this comprehensive exploration, we journey through the intricacies of this vital process, revealing its nuances and applications. As a leader in CNC machining services, Richconn is your trusted partner in achieving unparalleled quality and precision.view

Unlocking Precision: The Definitive Guide to Machined Surface Finish in CNC MachiningNovember 10, 2023Welcome to the realm of precision engineering, where the art of CNC machining meets the science of Machined Surface Finish. In this comprehensive exploration, we journey through the intricacies of this vital process, revealing its nuances and applications. As a leader in CNC machining services, Richconn is your trusted partner in achieving unparalleled quality and precision.view Surface Finish 101: An Overview of Plastic Surface Finish ChartSeptember 5, 2023A process that involves the use of a machine to impose characteristic irregularities on the surface of its product. Constant use tends to cause the product to wear down over time. This is usually due ...view

Surface Finish 101: An Overview of Plastic Surface Finish ChartSeptember 5, 2023A process that involves the use of a machine to impose characteristic irregularities on the surface of its product. Constant use tends to cause the product to wear down over time. This is usually due ...view![Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]](/uploads/image/20231123/14/chamfer-101-understanding-chamfers-and-chamfered-edge-quick-guide_400x400.webp) Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]November 23, 2023Gain comprehensive knowledge about chamfers, including types, advantages and limitations, various methods of measurement and a comparative feature analysis.view

Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]November 23, 2023Gain comprehensive knowledge about chamfers, including types, advantages and limitations, various methods of measurement and a comparative feature analysis.view Delrin Material vs Acetal: What Are Their Differences? (A Detailed Comparison)November 28, 2023Delrin Material vs Acetal: which is better? Let’s compare the two materials to help you decide which is better for your project.view

Delrin Material vs Acetal: What Are Their Differences? (A Detailed Comparison)November 28, 2023Delrin Material vs Acetal: which is better? Let’s compare the two materials to help you decide which is better for your project.view About PVD Surface Treatment Technology and Its ApplicationSeptember 16, 2022With the rapid development of the automobile industry and the improvement of the technological level, especially the wide application of high-strength plates in automobile sheet metal, the cold work d...view

About PVD Surface Treatment Technology and Its ApplicationSeptember 16, 2022With the rapid development of the automobile industry and the improvement of the technological level, especially the wide application of high-strength plates in automobile sheet metal, the cold work d...view Implant Abutment Materials and SelectionOctober 24, 2023Commonly used implant abutment materials can be divided into five categories: titanium (precision machining, polished, laser etched), surgical grade stainless steel, cast gold alloys, zirconium oxide, and polyether ether ketone (PEEK).view

Implant Abutment Materials and SelectionOctober 24, 2023Commonly used implant abutment materials can be divided into five categories: titanium (precision machining, polished, laser etched), surgical grade stainless steel, cast gold alloys, zirconium oxide, and polyether ether ketone (PEEK).view

EN

EN

ru

ru