When weighing your options, you need to find answers to a number of important questions - but what are they?

Does the supplier you are considering offer the manufacturing processes you need?

The best way to see for yourself is to visit.

Can the supplier deliver quickly enough?

Get assurances that manufacturing speed and capacity will meet your product development, launch and production needs.

Does the supplier have a minimum order quantity?

Some suppliers set a high minimum order quantity. If you only need small quantities initially, you are usually best served by an on-demand manufacturing service with no minimum quantity.

Does the quality control meet your requirements?

Is the standard offered suitable for your product? For example, quality control at a supplier for medical device parts should be much more stringent than for commercial products. Pay only for the level of quality you need.

Does the company work with the materials you need?

If a wide range of materials is important to you, on-demand manufacturing services often have the best selection in stock and have the specialized knowledge to use them to their best advantage. And they are also able to work with customer-supplied materials.

Will you get the design support you need?

If you're not a manufacturing expert yourself, it's best to choose a service that can support you and advise on the feasibility of your part or product.

-640x360_tcm27-98897.jpg)

In addition to the questions listed above, when choosing a manufacturer, you also need to consider whether a supplier can offer the benefits of digital manufacturing, including lower total cost of ownership (TCO).

TCO considers the direct and indirect costs of procuring and using a part or product throughout its lifecycle. Essentially, it is the purchase price plus additional costs such as shipping and logistics, warehousing, operations, maintenance and parts retirement. This is a better measure of value for money or return on investment than purchase price alone. Evaluating suppliers for TCO is also about quality, consistency and timely delivery, not just initial financial outlay.

Advanced manufacturing technologies are driving the new industrial revolution known as "Industry 4.0," and more suppliers are using automated processes to quickly and cost-effectively evaluate, plan and produce custom parts and products.

For example, some on-demand manufacturers offer cost advantages in the production of tools and parts. These are achieved through:

# services to manufacture a project or design from prototype to production. This reduces the cost and complexity of working with multiple vendors.

# Size and advanced automation of production facilities, resulting in on-time and timely delivery.

# Reducing inventory costs by offering buyers the flexibility to order only the quantities they need at any given time

# Managing fluctuations in demand: rapid production even when demand increases, avoiding the risk of lost sales opportunities

# Usage guarantees for injection molding projects. Certain suppliers offer a lifetime warranty on your molds, so there are no additional mold costs for repeat orders.

So it pays to take the time to find a supplier that is an exact fit for the buyer company. Think of it as a partnership that both parties are committed to and invested in. And in the digital age, it's increasingly advisable to look at additional total cost of ownership (TCO) savings as well.

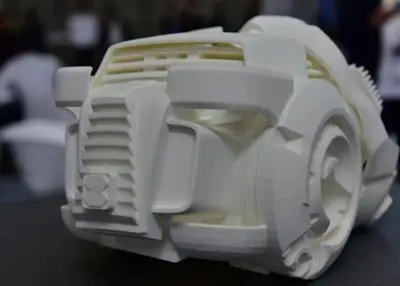

The Ultimate 3D Printing Guide: Types of 3D Printers, Materials & MoreApril 17, 2024Here is an ultimate guide to 3D printing technology, including types of 3D printers, materials, and more. Read on and choose the right one for your project.view

The Ultimate 3D Printing Guide: Types of 3D Printers, Materials & MoreApril 17, 2024Here is an ultimate guide to 3D printing technology, including types of 3D printers, materials, and more. Read on and choose the right one for your project.view CNC Machine Cost - Your Comprehensive Guide to Understanding and Navigating CostsNovember 2, 2023In today's fast-paced manufacturing world, the utilization of CNC (Computer Numerical Control) machines has become pivotal for businesses and hobbyists alike. These automated tools offer unparalleled precision and efficiency in various industries, from automotive to aerospace, and even the creation of intricate custom components. However, one question looms large for anyone considering CNC machining: What are the costs involved?view

CNC Machine Cost - Your Comprehensive Guide to Understanding and Navigating CostsNovember 2, 2023In today's fast-paced manufacturing world, the utilization of CNC (Computer Numerical Control) machines has become pivotal for businesses and hobbyists alike. These automated tools offer unparalleled precision and efficiency in various industries, from automotive to aerospace, and even the creation of intricate custom components. However, one question looms large for anyone considering CNC machining: What are the costs involved?view Richconn 2023 Chinese New Year Holiday NoticeDecember 2, 2022November 29, 2022Chinese New Year is approaching! We would like to remind you that Richconn will be on holiday to celebrate our Chinese New Year. For your convenience in arranging your project, please...view

Richconn 2023 Chinese New Year Holiday NoticeDecember 2, 2022November 29, 2022Chinese New Year is approaching! We would like to remind you that Richconn will be on holiday to celebrate our Chinese New Year. For your convenience in arranging your project, please...view What is Tensile Strength for CNC Machining?October 25, 2023Tensile strength is a key characteristic that engineers and materials specialists must consider when designing and selecting materials for their applications. It is the maximum stress that a material can withstand before it breaks or deforms under tension.view

What is Tensile Strength for CNC Machining?October 25, 2023Tensile strength is a key characteristic that engineers and materials specialists must consider when designing and selecting materials for their applications. It is the maximum stress that a material can withstand before it breaks or deforms under tension.view Boring Machining Process GuideNovember 22, 2023In CNC machining, boring technology is used as a precision machining process with a spindle mounted sleeve. Boring is a machining process in which the internal surface of a workpiece is cut by a rotating tool on a boring machine to determine the precise hole diameter and surface quality.view

Boring Machining Process GuideNovember 22, 2023In CNC machining, boring technology is used as a precision machining process with a spindle mounted sleeve. Boring is a machining process in which the internal surface of a workpiece is cut by a rotating tool on a boring machine to determine the precise hole diameter and surface quality.view Better CNC Parts Through Fine tuning of TolerancesOctober 13, 2023Tolerances that are too tight can require rework, which in turn drives up costs. If tolerances are too loose, the part may not fit with the mating part. So to optimize your designs, know what tolerances are needed and when: Standard tolerances can improve quality, ensure fast repeatability and reduce manufacturing costs.view

Better CNC Parts Through Fine tuning of TolerancesOctober 13, 2023Tolerances that are too tight can require rework, which in turn drives up costs. If tolerances are too loose, the part may not fit with the mating part. So to optimize your designs, know what tolerances are needed and when: Standard tolerances can improve quality, ensure fast repeatability and reduce manufacturing costs.view

EN

EN

ru

ru