The full name of CNC is Computer Numerical Control, and a tooling machine with a computer as the control center is called a CNC machine. The traditional tooling machines need to be manually operated to achieve a variety of metal processing techniques, CNC machine is by the engineers of the computer input product drawings, complete the product required tooling sequence, processing environment parameters and other data, by the computer according to the above instructions for automated production. CNC machine greatly reduces the consumption of materials and errors, and effectively improve the production efficiency, but also to complete the asymmetric modeling of the high degree of difficulty in the processing, has now become the mainstream equipment in the manufacturing industry. It has become the mainstream equipment in the manufacturing industry.

In addition to the continuation of the standard equipment of the traditional tooling machine, such as the ability to machine metal tools, fixtures used to fix the workpiece, etc., CNC machine more computerized operation panel, can read the product file to achieve low error processing. Advanced CNC machine computers even take care of changing tools, putting on raw materials and removing finished products, eliminating metal shavings and other operations that originally required a lot of manpower, saving a lot of time for manual operation. In addition to controlling the processing process of the brain, CNC machine also needs to assist the body to processing. Depending on the degree of precision, CNC machines are equipped with different robotic arms or spindle heads that can manipulate the machining angle... All of these precision equipments make CNC machines capable of creating a wide variety of high-precision products.

Lathe machining is a processing method that rotates the metal material at high speed and cuts it with a tool in the corresponding part. CNC lathe can complete the above commands through computerized signals, which greatly reduces the possibility of human error and improves the product accuracy and production speed. It is suitable for products that require a large number of lathes.

The so-called milling machine is a processing method in which the tool rotates at high speed and cuts on the static metal material. Similarly, as long as the machine is specialized in milling and the production process is controlled by a computer, it is called a CNC milling machine. Advantages are the same as CNC lathe, computerized control of the machining sequence, feed angle and feed speed, so as to reduce the defective rate of the product. It is suitable for products that require a large number of milling machines.

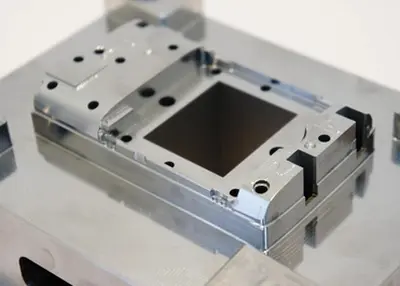

When a CNC machine integrates various machining methods such as lathe and milling machine, it can be called CNC machining center machine. Many machined parts need to go through different kinds of machining methods, then the machining center machine can integrate many machining steps, reduce the time of handling workpieces, automated replacement of cutting tools, do not have to recalibrate the machining coordinates on different machining machines, etc., and can produce products of high complexity.

Horizontal CNC machines usually have horizontal tools that move the XYZ axes of the workpiece to machine the vertical surfaces of the workpiece. Horizontal machines offer several benefits, such as more space for machining and the ability to machine large workpieces. Some horizontal CNC machines even eliminate the need to manually change surfaces, simply by rotating and moving the four sides of the workpiece, the other surfaces can be machined with a high degree of accuracy, avoiding the errors associated with manual changeovers. Moreover, since the tool is cut from the horizontal plane, metal chips will easily fall into the chipformer, thus preventing metal chips from affecting the machining accuracy of the tool, and thus prolonging tool life. However, horizontal CNC machines are large and can cost up to ten million dollars, so smaller factories are generally more difficult to get a horizontal CNC machine.

Compared to horizontal CNC machines with horizontal tools, vertical CNC machines mainly place the tool on top of the workpiece and move the XYZ axis of the workpiece to adjust the machining angle. Because the body occupies less space, and the cost of the machine falls in the seven-digit range, so the vertical machine is also more frequently used by enterprises, but also because of its small size, so it is not suitable for large-scale workpiece machining, more suitable for narrow workpieces. In addition, the vertical machining angle is intuitive, easy for operators to judge the tool path in the process of machining in time to fine-tune the parameters, is a major advantage of vertical CNC machine. In addition to the dimensional requirements of the workpiece, chips tend to accumulate during the cutting operation, so it is necessary to periodically spray air or coolant to remove the chips from the machining surface.

When the workpiece is asymmetrical or has an irregular design, a multi-axis CNC machine can realize such highly complex products. In addition to the original XYZ axes to move the workpiece, additional movable axes are added to the tool to allow the tool to cut into the product at multiple angles, ensuring that the tool is always perpendicular to each face of the workpiece, with the added benefit of protecting the tool and minimizing errors. Products of high complexity often go through many processes, using different tools with different machining angles, speeds, and depths, so multi-axis CNC machines are the best solution for this type of high complexity product.

The versatility and wide range of applications of CNC machines have made them a key tool in modern manufacturing. Whether you are producing large workpieces or highly complex products, CNC machines offer efficient, high-precision machining solutions. Therefore, as technology continues to evolve, CNC machine tables will continue to drive manufacturing forward, bringing more innovation and opportunities to a variety of industries.

Finally, take a look at Richconn, a precision manufacturing company founded in 2008. We offer CNC machining services, sheet metal services, and plating services to provide a comprehensive solution for our customers. No matter what type of CNC machine processing you require, Richconn can provide you with expert support to ensure that your product meets the high standards of quality and performance required. If you have any questions or need further information, please feel free to contact Richconn and they will be happy to assist you.

A Comprehensive Guide to Choosing CNC Machining ToolsJuly 19, 2023Description:Discover how to select suitable CNC machining tools through this comprehensive guide. Explore key considerations for choosing CNC machining tools, different tool types, and expert advice t...view

A Comprehensive Guide to Choosing CNC Machining ToolsJuly 19, 2023Description:Discover how to select suitable CNC machining tools through this comprehensive guide. Explore key considerations for choosing CNC machining tools, different tool types, and expert advice t...view Carbon Steel vs Cast Iron: Which Is Better for CNC Machining?November 24, 2023Carbon steel and cast iron are two common types of metal materials that are used for CNC machining. They are both composed of iron and carbon, but they have different amounts of carbon and different structures.view

Carbon Steel vs Cast Iron: Which Is Better for CNC Machining?November 24, 2023Carbon steel and cast iron are two common types of metal materials that are used for CNC machining. They are both composed of iron and carbon, but they have different amounts of carbon and different structures.view Material Comparison: Difference between High Speed Steel and Tungsten SteelOctober 31, 2023Materials play a vital role in modern industry, and in the field of precision manufacturing, both high-speed steel and tungsten steel are highly regarded materials. They have an important position in the field of tool, mold and mechanical parts manufacturing, etc. However, there are obvious differences between them in terms of characteristics, features, application areas, etc. In this article, we will introduce and compare them. This article will be introduced and compared.view

Material Comparison: Difference between High Speed Steel and Tungsten SteelOctober 31, 2023Materials play a vital role in modern industry, and in the field of precision manufacturing, both high-speed steel and tungsten steel are highly regarded materials. They have an important position in the field of tool, mold and mechanical parts manufacturing, etc. However, there are obvious differences between them in terms of characteristics, features, application areas, etc. In this article, we will introduce and compare them. This article will be introduced and compared.view What Is A Coordinate Measuring Machine Used For?July 16, 2024A coordinate measuring machine is often used to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about it to ensure every part you make meets and exceeds your expectations.view

What Is A Coordinate Measuring Machine Used For?July 16, 2024A coordinate measuring machine is often used to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about it to ensure every part you make meets and exceeds your expectations.view CNC Control Systems: Unraveling the Core of Computer Numerical ControlNovember 3, 2023Are you ready to delve into the heart of modern manufacturing technology? Welcome to the world of CNC Control Systems, where precision and automation meet to revolutionize industries.view

CNC Control Systems: Unraveling the Core of Computer Numerical ControlNovember 3, 2023Are you ready to delve into the heart of modern manufacturing technology? Welcome to the world of CNC Control Systems, where precision and automation meet to revolutionize industries.view Rubber mold customization:know everything about design, material selection and manufacturingDecember 18, 2023Introduction:Custom rubber mold making is a complex process that involves issues such as design, materials, manufacturing, inspection, production, maintenance, and so on. The aim of this article is to...view

Rubber mold customization:know everything about design, material selection and manufacturingDecember 18, 2023Introduction:Custom rubber mold making is a complex process that involves issues such as design, materials, manufacturing, inspection, production, maintenance, and so on. The aim of this article is to...view

EN

EN

ru

ru