Screws the most common fasteners used to create removable threaded connections in household appliances, industrial equipment, transportation, building structures and other machines and mechanisms. Consider the varieties of bolts, the materials of construction, and the characteristics of their manufacture.

Bolts consist of a cylindrical rod with a screw slot at one end and a head at the other, designed to create a removable connection. Depending on the shape of the head, there are several types of bolts:

Hexagonal;

Round;

Oval;

Square;

Semi-circular.

The most common are bolts with hexagonal heads for connections subjected to loads of various natures - static, cyclic and dynamic. They are actively used in the automotive industry for the connection of parts that operate in harsh conditions - fastening connecting rods, crankshaft covers, connecting the heads of cylinder blocks, as well as elements of the chassis.

Thread diameter and smooth part of the rod;.

Thread length and total rod length.

Normal or reduced diameter of the head.

Bolts are manufactured with three types of accuracy - rough, normal and increased. According to this indicator, the hardware is distinguished by the accuracy of geometric dimensions, the magnitude of deviation from the nominal shape and cosmetic defects, which are regulated by the provisions of the standard.

Most often, bolts with metric threads are applied to the outside of the rod. The shape of the grooves and protrusions form isosceles triangles. The unit of measurement is the millimeter. Hardware with pipe, trapezoidal, thrust or rectangular threads is less common.

Zinc - the most common anticorrosive coating, which provides anodic protection of steel from atmospheric influences at normal and low temperatures.

Cadmium - is rare in modern industry, due to the toxicity of this chemical element and its compounds. Also, performance properties are comparable to zinc coatings.

Nickel - is cathodic with respect to steel, so the coating is used to improve the visual quality of hardware. The main field of application is the production of furniture.

Phosphatizing is the chemical treatment of surfaces with special compounds, which results in the formation of phosphate films with high protective properties. The type of crystal structure depends on the quality of the prepared alkali; and

Oxidizing is the formation of an oxide film on the surface of the bolt with protective properties close to those of a phosphate coating.

The best characteristic is the zinc flake coating, which does not include hexavalent chromium. Aluminum and zinc flakes provide protective properties.

During lot acceptance, a control sample of the product is checked for compliance with the following mechanical properties:

Time resistance is the ratio of the maximum load to the original cross-section.

Yield strength is the lowest stress at which there is no significant increase in tensile load when deformation of the material occurs.

Elongation is the ratio of the length of the sample after rupture to the original value.

Brinell hardness is the ratio of force to the printed area left by the identifier.

Impact strength is the total work expended on the deformation and destruction of the preformed sample.

The strength rating of a bolt depends on the type of steel used to make the hardware. Mechanical properties and test methods for bolts, screws, and studs are governed by current standards that specify strength grades, material types, chemical compositions, and minimum release temperatures.

Hardware with a strength of 3.6 - 6.8 is made of carbon steel.

Hardware with a strength of 8.8 - 12.9 is made of carbon steel without additives or alloying elements, hardened and released.

Hardware made of austenitic, martensitic and ferritic steel grades meets the requirements of GOST ISO 3506-1-2014.

In the mass production of bolts, Cold chamber die casting technology is used, which makes it possible to produce products of suitable quality in large quantities.

The stability of the process depends to a large extent on the quality of the workpiece. During the stamping process, surface defects can lead to cracks and tears. In order to reduce the rejection rate, the pre-stripping of blanks is carried out mechanically or by fire methods.

Pre-stripping of workpieces results in minimal decarburization, which reduces the likelihood of forming deep punches and scratches. In order to remove the oxide film, which can lead to premature wear of technical equipment, they resort to etching the surface with an acid solution, followed by washing under pressure with cold or hot water. In order to neutralize the acid residues, the use of lime under the influence of high temperatures is permitted. In addition, this process helps to reduce the coefficient of friction during calibration or cold stamping.

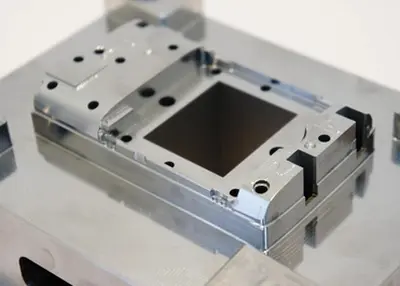

Small-scale production of bolts using turning, milling, drilling and grinding machines begins with the development of technical drawings, calculation of blanks, allowances and cutting patterns.

The production of non-standard bolts is a popular service for many manufacturing companies that have improved their processes. In order to produce a new type of product, sometimes original shape or hardware with increased strength is required. Construction organizations often order the manufacture of foundation and footbolt bolts of non-standard design, depending on the characteristics of the production site and working conditions.

Richconn was founded in 2008, for the manufacturing of bolts and fasteners, we have 16 years of production experience, Richconn can provide you with bolts CNC machining services, quickly contact us for a cheap quote!

Hot Rolled vs Cold Rolled: Which One Is Right for Your Project?February 26, 2024To optimize the properties of steel for specific applications, it is necessary to consider factors beyond its chemical composition. Hot rolling or cold rolling is a process employed to enhance the sha...view

Hot Rolled vs Cold Rolled: Which One Is Right for Your Project?February 26, 2024To optimize the properties of steel for specific applications, it is necessary to consider factors beyond its chemical composition. Hot rolling or cold rolling is a process employed to enhance the sha...view Choosing the Optimal Material For CNC Machining.October 17, 2023If you find the vast selection of different materials for CNC machining confusing, this blog will tell you how to reduce that number to a manageable level.

Choosing the right material for CNC machining can make all the difference in getting a working part or prototype made at a reasonable price.view

Choosing the Optimal Material For CNC Machining.October 17, 2023If you find the vast selection of different materials for CNC machining confusing, this blog will tell you how to reduce that number to a manageable level.

Choosing the right material for CNC machining can make all the difference in getting a working part or prototype made at a reasonable price.view What Kind of Common CNC Metal Machining Technology Do You Know?August 10, 20221. CNC metal machining technology: selective laser meltingIn a tank filled with metal powder, a computer-controlled high-power carbon dioxide laser selectively sweeps the surface of the metal powder. ...view

What Kind of Common CNC Metal Machining Technology Do You Know?August 10, 20221. CNC metal machining technology: selective laser meltingIn a tank filled with metal powder, a computer-controlled high-power carbon dioxide laser selectively sweeps the surface of the metal powder. ...view Resin Materials: What They Are, How They Differ, and How to Use ThemDecember 8, 2023Resin materials are synthetic or natural substances that can be molded or shaped into various forms. They are widely used in many industries and applications, such as art, crafts, jewelry, furniture, electronics, medical, aerospace, etc.view

Resin Materials: What They Are, How They Differ, and How to Use ThemDecember 8, 2023Resin materials are synthetic or natural substances that can be molded or shaped into various forms. They are widely used in many industries and applications, such as art, crafts, jewelry, furniture, electronics, medical, aerospace, etc.view The Working Principle of CNC Cutting Aluminum SheetsFebruary 29, 2024The Intricacies of CNC Cutting Aluminum SheetsIn the intricate world of manufacturing and fabrication, CNC cutting aluminum sheets has become a cornerstone practice, heralding a new era of precision a...view

The Working Principle of CNC Cutting Aluminum SheetsFebruary 29, 2024The Intricacies of CNC Cutting Aluminum SheetsIn the intricate world of manufacturing and fabrication, CNC cutting aluminum sheets has become a cornerstone practice, heralding a new era of precision a...view Rubber mold customization:know everything about design, material selection and manufacturingDecember 18, 2023Introduction:Custom rubber mold making is a complex process that involves issues such as design, materials, manufacturing, inspection, production, maintenance, and so on. The aim of this article is to...view

Rubber mold customization:know everything about design, material selection and manufacturingDecember 18, 2023Introduction:Custom rubber mold making is a complex process that involves issues such as design, materials, manufacturing, inspection, production, maintenance, and so on. The aim of this article is to...view

EN

EN

ru

ru