Welcome to the realm of precision and durability, where machined steel takes center stage. In this comprehensive exploration, we'll navigate through the intricacies of machined steel, unveil its diverse applications, compare various types, delve into performance metrics, examine Richconn's CNC machining advantages, and provide essential knowledge on mechanical machining. Let's embark on this detailed journey, ensuring each section is rich with information.

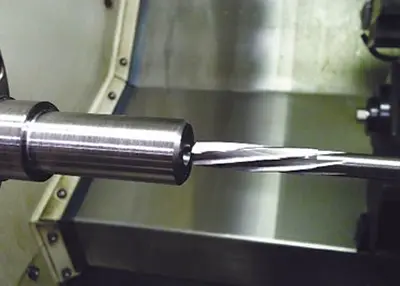

Machined steel is not just a material; it's a testament to precision engineering. The process involves the removal of material from a workpiece to achieve the desired shape and size. The machining methods vary, including CNC turning, CNC milling, and drilling. To fully grasp the basics, let's explore the machining techniques that transform raw steel into finely crafted components.

| Technique | Description |

|---|---|

| Turning | Rotating the workpiece while a cutting tool shapes it. |

| Milling | Utilizing rotary cutters to remove material from a workpiece. |

| Drilling | Creating holes using a drill bit or other cutting tools. |

Machined steel's versatility shines in its applications across diverse industries. From aerospace to automotive, let's explore how machined steel plays a pivotal role in shaping the modern world.

In the aerospace industry, machined steel components ensure the structural integrity of aircraft. Precision parts, such as turbine blades and landing gear components, demand the highest quality machining to meet stringent safety standards.

Machined steel's impact on the automotive sector is profound. From engine components to transmission parts, the automotive industry relies on the durability and precision of machined steel for optimal performance.

In the medical field, machined steel contributes to the manufacturing of intricate surgical instruments and medical devices. The biocompatibility and precision of machined steel are crucial in creating tools that save lives.

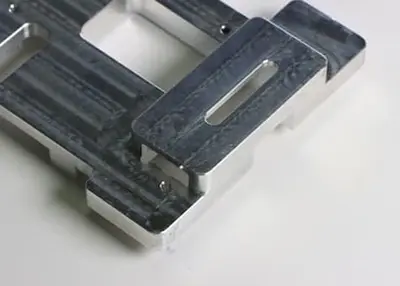

Not all machined steel is created equal. Various alloys and compositions cater to specific needs. Let's delve into a comparative analysis of different machined steel types, examining their strengths, weaknesses, and ideal applications.

| Property | Carbon Steel | Alloy Steel |

|---|---|---|

| Strength | Moderate to High | High |

| Toughness | Good | Excellent |

| Corrosion Resistance | Low | Varies based on alloy composition |

| Ideal Applications | Structural components, machinery parts | High-stress applications, aerospace |

| Stainless Steel Type | Composition | Applications |

|---|---|---|

| 304 Stainless Steel | Chromium, Nickel | Food processing, architecture |

| 316 Stainless Steel | Chromium, Nickel, Molybdenum | Medical devices, marine applications |

Machined steel's performance is not solely determined by its type but also by its specific properties and adherence to stringent specifications. Let's delve into the nuanced aspects of machined steel performance and the technical specifications that guide its application.

Understanding the mechanical properties is crucial for selecting the right machined steel for a particular application. The key properties include:

Hardness: The resistance of machined steel to deformation or scratching.

Tensile Strength: The maximum stress a material can endure without breaking.

Yield Strength: The stress at which a material begins to deform plastically.

Impact Toughness: The ability of machined steel to absorb energy under impact.

Precision in machining is not just an art; it's a science. Meeting specific technical specifications and industry standards is paramount. Richconn adheres to international standards, ensuring that every machined steel component meets or exceeds the requirements for:

Dimensional Accuracy: Precise adherence to specified measurements.

Surface Finish: Achieving the desired surface texture and quality.

Tolerance Levels: Ensuring components meet specified tolerances.

Choosing the right supplier for machined steel is a critical decision that directly impacts the quality and success of your projects. Let's explore the factors that set Richconn apart and guide you through the intricacies of machined steel pricing.

Richconn stands as a reliable partner, offering a spectrum of CNC machining services. Our commitment to excellence is reflected in:

State-of-the-Art Equipment: Utilizing advanced CNC machining technology.

Expertise Across Industries: Catering to diverse sectors with precision.

Customization Options: Tailoring solutions to meet unique project requirements.

Understanding the factors influencing machined steel pricing empowers you to make informed decisions. Pricing considerations include:

Material Costs: Varied costs associated with different machined steel types.

Complexity of Machining: Intricacy of the design and machining process.

Volume and Batch Size: Economies of scale influencing pricing.

To truly appreciate machined steel, understanding the essence of mechanical machining is imperative. This section explores the fundamental concepts, techniques, and the pivotal role Richconn plays in ensuring precision through advanced mechanical machining processes.

Mechanical machining is more than just cutting metal; it's a meticulous craft. Richconn employs a range of techniques, including:

Turning: Rotating the workpiece to shape it.

Milling: Employing rotary cutters to remove material.

Drilling: Creating holes using drill bits.

Richconn's CNC machining prowess is a result of a comprehensive approach to precision. Our methods include:

Computer-Aided Design (CAD): Translating designs into machine-readable code.

Computer Numerical Control (CNC): Ensuring unparalleled accuracy in machining.

Quality Assurance Protocols: Rigorous checks to guarantee precision.

Richconn stands at the forefront of CNC machining services, delivering not just components but solutions. Explore the facets that define Richconn's advantages and set it apart as your trusted partner in precision machining.

Richconn invests in cutting-edge CNC machining equipment, ensuring:

High Speed and Precision: Meeting tight tolerances with speed.

Multi-Axis Machining: Enabling complex geometries.

Efficiency and Consistency: Delivering reliable results, every time.

Quality is not a compromise at Richconn; it's a commitment. Our quality control includes:

Advanced Inspection Tools: Utilizing state-of-the-art measuring equipment.

Traceability Protocols: Ensuring accountability throughout the production process.

ISO Certification: Complying with international quality management standards.

Real success lies in the satisfaction of our customers. Explore how Richconn's CNC machining services have fueled success stories across industries, attesting to our commitment to excellence.

As we conclude this exploration into machined steel and Richconn's CNC machining excellence, the journey doesn't end here. Whether you're seeking precision components or a reliable CNC machining partner, Richconn invites you to elevate your projects to new heights. Connect with us today and experience the fusion of innovation, precision, and excellence in every machined steel masterpiece.

Contact us to discuss your project requirements, explore customization options, and witness the unparalleled precision that Richconn brings to the world of CNC machined steel. Your journey to precision begins with a click or a call – reach out to Richconn now!

7 Best Tips for Sandblasting (The Complete Basics to Get Started)August 24, 2023Sandblast is a process that has been used for many years. It is used to clean, etch, and prepare surfaces before they are painted or coated with another material. Unfortunately, sandblasters are machi...view

7 Best Tips for Sandblasting (The Complete Basics to Get Started)August 24, 2023Sandblast is a process that has been used for many years. It is used to clean, etch, and prepare surfaces before they are painted or coated with another material. Unfortunately, sandblasters are machi...view What Is Reaming & Reamer And Their DifferencesSeptember 26, 2023Reaming is an important process in CNC machining services, and its main purpose is to join parts or components so that they can rotate or oscillate relative to each other and move at a specific angle or direction.view

What Is Reaming & Reamer And Their DifferencesSeptember 26, 2023Reaming is an important process in CNC machining services, and its main purpose is to join parts or components so that they can rotate or oscillate relative to each other and move at a specific angle or direction.view CNC Milling Definition Guide (Latest Insights for 2023)September 8, 2023CNC milling is a process of using a computer-controlled rotating cutting tool to remove material from a workpiece and create a custom-designed part or product. Milling is one of the most common types ...view

CNC Milling Definition Guide (Latest Insights for 2023)September 8, 2023CNC milling is a process of using a computer-controlled rotating cutting tool to remove material from a workpiece and create a custom-designed part or product. Milling is one of the most common types ...view Understanding Steel Material for Custom Prototyping: Properties, Grades, and ApplicationsMarch 14, 2024Let’s explore the diverse properties, grades and uses of steel material in prototyping, from its melting point to its versatility across different industry sectors.view

Understanding Steel Material for Custom Prototyping: Properties, Grades, and ApplicationsMarch 14, 2024Let’s explore the diverse properties, grades and uses of steel material in prototyping, from its melting point to its versatility across different industry sectors.view What Will Determine the Precision of CNC Machining?August 10, 2022In the preparation of CNC machining programs, proper use of methods and techniques is of great significance to ensure and improve the machining accuracy of CNC machine tools. So what determines the ma...view

What Will Determine the Precision of CNC Machining?August 10, 2022In the preparation of CNC machining programs, proper use of methods and techniques is of great significance to ensure and improve the machining accuracy of CNC machine tools. So what determines the ma...view Carbon Steel vs Cast Iron: Which Is Better for CNC Machining?November 24, 2023Carbon steel and cast iron are two common types of metal materials that are used for CNC machining. They are both composed of iron and carbon, but they have different amounts of carbon and different structures.view

Carbon Steel vs Cast Iron: Which Is Better for CNC Machining?November 24, 2023Carbon steel and cast iron are two common types of metal materials that are used for CNC machining. They are both composed of iron and carbon, but they have different amounts of carbon and different structures.view

EN

EN

ru

ru