In past communications with customers, we often encounter these situations:

1. The customer's drawings only specify the color, without specific requirements.

2. The customer's technical requirements only have rendered images, without color codes.

3. The customer only has a sample, without textual descriptions.

These situations lead to a common problem when doing surface treatment of parts: when should we choose spray paint versus powder coating? Surface treatment is crucial for the appearance, durability, and functionality of parts. In this article, we will delve into the factors that influence the choice between spray paint or powder coating for surface treatment. By understanding these factors, you will be able to make informed decisions during part machining to choose the appropriate surface treatment method.

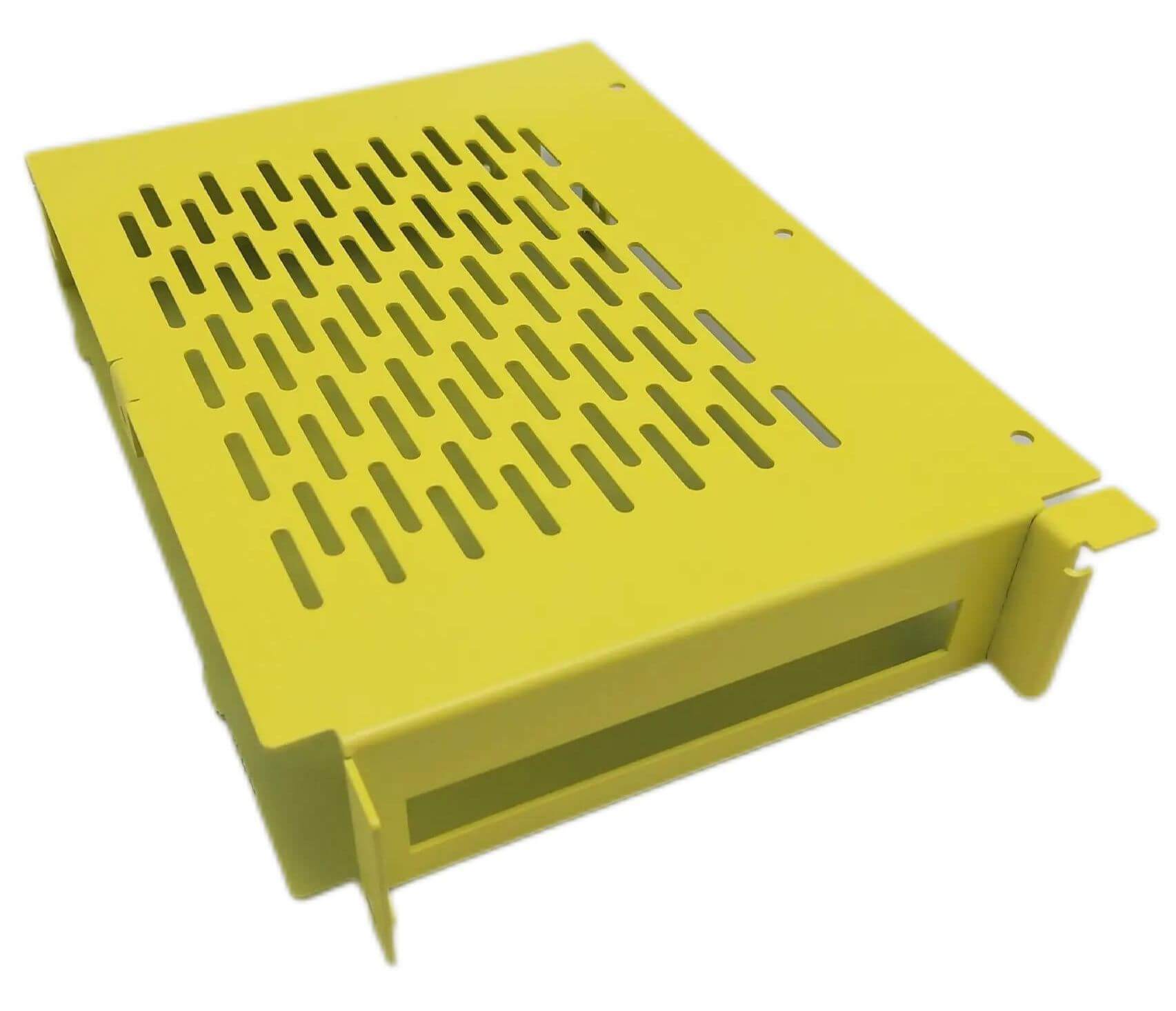

Spray Paint Effects

Determining the applicable surface treatment method (spray paint or powder coating) depends on several factors. Here are 6 key elements for discussion that I hope will help you:

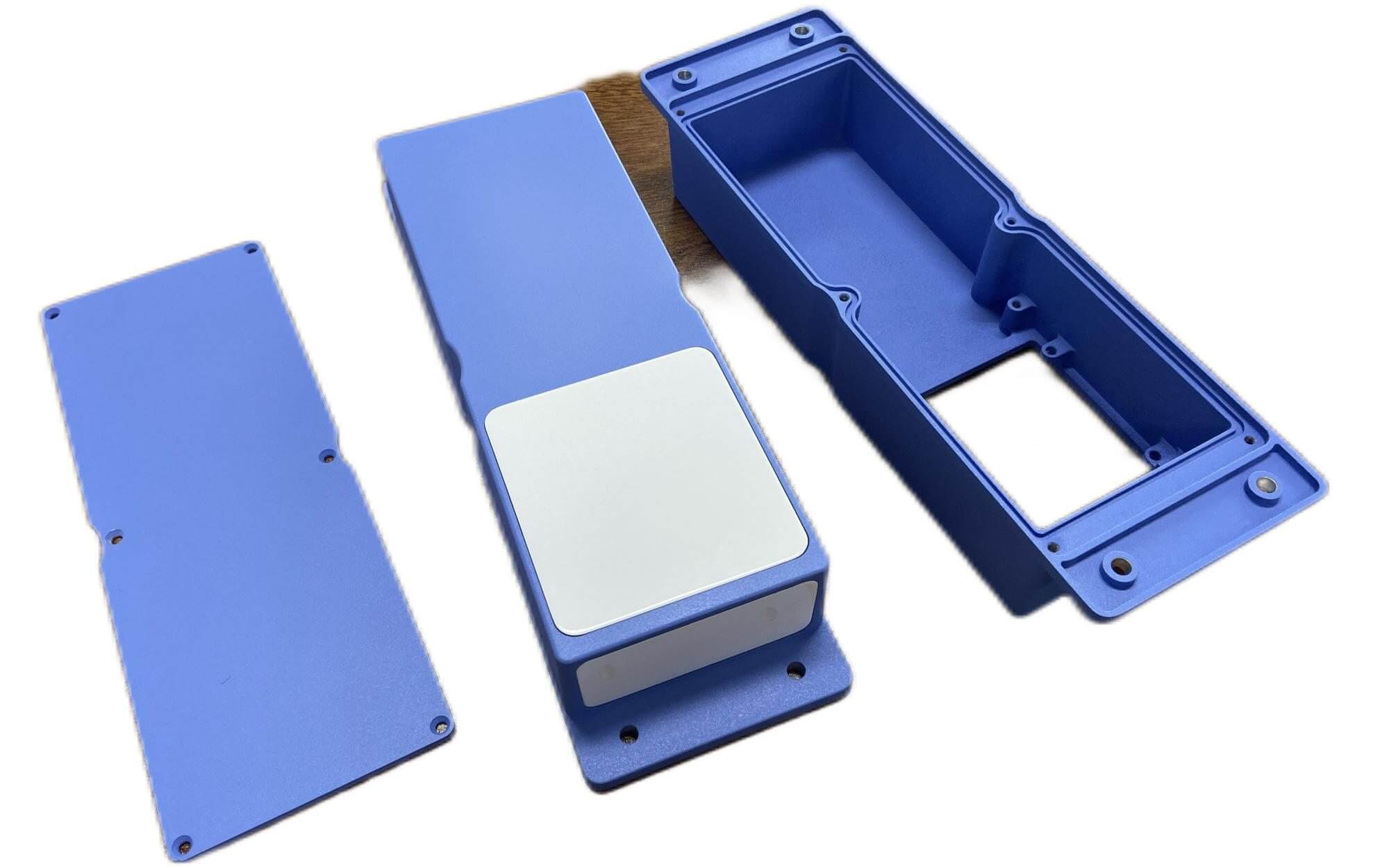

The primary consideration when determining the surface treatment method is the quality requirements of the part. Different surface treatment methods provide different levels of quality, performance, and aesthetic effect. If the part needs a smooth, glossy surface finish, spray paint is often chosen, such as for indoors aesthetics parts (like the one above). On the other hand, if a more durable, abrasion resistant surface is needed, especially for parts exposed to harsh environments or high wear, powder coating is preferred, such as for auto bodies, equipment cabinets, etc. (like the one below).

Powder Coating Effect 1

The material and surface finish of the part is another key factor in determining the applicable surface treatment method. Different materials and surface finishes will react differently to spray paint and powder coating. Compatibility with the surface treatment method must be considered to avoid any adverse reactions (poor adhesion) or quality reduction (poor surface effect). Testing and consulting our surface treatment experts can help determine the optimal process for specific materials and surface finishes.

Powder Coating Effect 2

Cost is an important factor in choosing which surface treatment method to use. We should also consider cost when choosing between spray paint and powder coating. For small batch or highly customized production, spray paint is often more cost-effective. On the other hand, for large batch production, powder coating is more economical because it reduces material waste and improves processing efficiency. In China, both spray paint and powder coating are produced in specialized licensed facilities. They are relatively more expensive specialty processes.

Auto Powder Coating

In recent years, environmental factors have become increasingly important in manufacturing processes. Industrial recycling and eco-friendly processes are our constant pursuit. Both spray paint and powder coating involve the use of solvents and chemicals which, if handled improperly, can be hazardous to the environment. On the other hand, powder coating is considered more eco-friendly because it produces less waste and avoids the use of solvents. Evaluating environmental impact is crucial for making sustainable surface treatment choices, which is our common goal.

Spray Paint Effect 2

Seeking advice from experts or senior engineers in the field can provide valuable input to confirm the proper surface treatment method. Consulting professionals with extensive experience in surface treatment processes can assist you in making informed decisions based on the specific requirements of the part. Consulting us can provide guidance on best practices, lessons learned, applicable materials, pretreatments, related parameters, post-treatment processes, as well as the pros and cons of spray paint and powder coating.

Conducting testing and validation is critical to determine the optimal surface treatment method for a part. These tests can involve analyzing the quality, durability, and performance of parts after different surface treatment processes. By comparing the results, you can determine the surface treatment method that best meets the requirements. We offer the most comprehensive testing capabilities for both spray paint and powder coating, although some advanced tests do incur additional charges.

A: Spray painting can provide smooth, glossy surface treatment effects that are ideal for parts where aesthetic appearance is important. It also offers corrosion resistance and cost-effectiveness for small batch production.

A: Powder coating is recommended for surface treatment of parts that need enhanced durability, wear resistance, and withstand harsh environments. Since powder coating is more efficient with lower material waste, it is typically better suited for large batch production.

A: Although spray painting can provide ideal surface treatment effects, it may involve the use of environmentally hazardous solvents and chemicals. Proper safety and environmental guidelines must be followed when spray painting.

A: Consulting experts and conducting material compatibility testing is very important for determining the applicability of surface treatments on different materials. Compatibility testing helps identify any adverse reactions or quality issues.

A: Cost is an important factor in any manufacturing process. Typically spray painting is more cost effective for small batch production, while powder coating is more economical for large batches since it reduces material waste and improves processing efficiency.

A: Experts in surface treatment processes have extensive knowledge and experience that can provide valuable insights for determining the appropriate surface treatment method. They can guide you in following best practices, selecting suitable materials, and help make informed decisions based on specific requirements.

A: Areas of regular parts that cannot be surface treated typically need to be masked prior to processing and unmasked after completion. Irregular areas may require customized masking materials. This is very important to detail with our engineers prior to surface treatment.

A: Common ones we discuss are thickness testing, adhesion testing, hardness testing, corrosion testing, impact testing, bend testing, smoothness testing, wear testing, color testing, cure testing. These require dedicated test equipment and procedures.

When selecting between spray paint or powder coating surface treatment methods, it is important to carefully consider various factors. By evaluating quality requirements, material compatibility, cost considerations, environmental impact, and seeking expert advice, you can determine the optimal surface treatment for your machined parts. Remember to conduct testing and validation to verify the efficacy of your chosen surface treatment method. Making informed decisions will ensure your parts receive enhanced appearance, durability, and functionality from the best surface treatment.

What is a CNC Lathe? Definitions, Uses, Types & BenefitsMarch 29, 2024This article provides a comprehensive introduction to CNC lathes, including their types, applications, benefits, and more. Read on and get detailed information.view

What is a CNC Lathe? Definitions, Uses, Types & BenefitsMarch 29, 2024This article provides a comprehensive introduction to CNC lathes, including their types, applications, benefits, and more. Read on and get detailed information.view The Application of CNC Machining in Mechanical Equipment - SheetMay 7, 2024Let’s explore the world of sheet in mechanical equipment! Read this article to discover its importance, applications, manufacturing processes, and more.view

The Application of CNC Machining in Mechanical Equipment - SheetMay 7, 2024Let’s explore the world of sheet in mechanical equipment! Read this article to discover its importance, applications, manufacturing processes, and more.view Introduction to MetalworkingOctober 24, 2023Humans have developed many methods of metal fabrication, which is the processing of metal into various shape types. Here we will introduce some of the concepts and processes of this metal working method.view

Introduction to MetalworkingOctober 24, 2023Humans have developed many methods of metal fabrication, which is the processing of metal into various shape types. Here we will introduce some of the concepts and processes of this metal working method.view Precision at Work: CNC Advancements in the Electronic SectorJuly 2, 2024Let’s discover the great impact of CNC technology in the electronic sector. Explore how precision, efficiency, and innovation converge to reshape electronic manufacturing processes, driving advancements and elevating industry standards to new heights.view

Precision at Work: CNC Advancements in the Electronic SectorJuly 2, 2024Let’s discover the great impact of CNC technology in the electronic sector. Explore how precision, efficiency, and innovation converge to reshape electronic manufacturing processes, driving advancements and elevating industry standards to new heights.view 7 Applications of CNC Machining Medical Parts ManufacturingOctober 25, 2023The medical industry is constantly innovating and finding ways to improve the quality of life and outcomes for patients. One such technology, computer numerical control (CNC) machining, has become a revolutionary tool in medical hardware manufacturing. In this rapidly evolving field, CNC machines not only provide a high level of precision and accuracy, but are also able to cope with a wide range of materials and complex geometries.view

7 Applications of CNC Machining Medical Parts ManufacturingOctober 25, 2023The medical industry is constantly innovating and finding ways to improve the quality of life and outcomes for patients. One such technology, computer numerical control (CNC) machining, has become a revolutionary tool in medical hardware manufacturing. In this rapidly evolving field, CNC machines not only provide a high level of precision and accuracy, but are also able to cope with a wide range of materials and complex geometries.view Five Axis CNC Machine Tool: Precision Machining of Carbon Fiber Composite MaterialsMay 22, 2023Further CNC cutting and drilling of raw carbon fiber parts is necessary to meet the precision requirements or assembly needs. According to new material introductions, carbon fiber reinforced composite...view

Five Axis CNC Machine Tool: Precision Machining of Carbon Fiber Composite MaterialsMay 22, 2023Further CNC cutting and drilling of raw carbon fiber parts is necessary to meet the precision requirements or assembly needs. According to new material introductions, carbon fiber reinforced composite...view

EN

EN

ru

ru