In the realm of precision engineering, where intricacy meets innovation, the quest for superior precision components drives industries forward. At Richconn, we don't just craft components; we sculpt reliability and precision. Prepare to delve deep into the world of precision components with us, discovering the nuances, intricacies, and pathways to excellence.

Precision components are the epitome of engineering excellence, meticulously designed and manufactured to exacting standards. These parts, ranging from micro-sized gears to intricate medical implants, adhere to extremely tight tolerances, ensuring seamless integration within complex systems. Whether it's aerospace, automotive, medical, or electronics, precision components serve as the backbone, dictating the functionality and reliability of the final product.

Precision engineering transcends mere manufacturing; it's an art form that demands mastery of materials, cutting-edge technologies like CNC machining, and a profound understanding of the end application. Each component embodies a symphony of precision, durability, and performance, crafted to function seamlessly in critical systems where accuracy is paramount.

The landscape of precision components spans diverse categories, each tailored to specific applications and industries. These categories include:

Mechanical Precision Components: From gears and shafts to bearings and couplings, these components power machinery, ensuring smooth operation and precise motion control.

Electronic Precision Components: Integrated circuits, connectors, and sensors represent the heart of modern electronics, where nanoscale precision is non-negotiable for performance and reliability.

Medical Precision Components: Implants, prosthetics, and surgical instruments demand uncompromising precision to ensure compatibility, functionality, and biocompatibility within the human body.

Automotive Precision Components: Critical components like fuel injectors, engine parts, and transmission components require precision engineering to enhance fuel efficiency, performance, and safety.

Each category exhibits its unique set of challenges, materials, and manufacturing techniques. For instance, electronic precision components demand nanoscale accuracy, while medical counterparts prioritize biocompatibility and durability.

The creation of precision components transcends traditional manufacturing. It's a synergy of art and science, relying on advanced technologies and craftsmanship to achieve perfection. Computer-Aided Design (CAD) plays a pivotal role, enabling precise visualization and simulation of components before actual production. This minimizes errors and optimizes designs for functionality and manufacturability.

The manufacturing process itself often involves CNC machining machining, a versatile technology revered for its precision, repeatability, and ability to work with various materials. Whether it's CNC milling machining , CNC turning machining , or grinding, CNC machining ensures high-quality, intricate components that meet exact specifications.

Achieving precision isn't solely about machining; it's a holistic approach involving stringent quality control measures, material selection, and a deep understanding of how each component integrates into the larger system.

In the quest for superior precision components, identifying trustworthy suppliers becomes pivotal. The process involves strategic steps to ensure alignment with quality, reliability, and delivery requirements.

Begin by defining your needs precisely. Outline technical specifications, tolerances, materials, and volume requirements. This clarity forms the foundation for a successful partnership with a supplier.

Next, explore various avenues to discover potential suppliers. Online directories, industry exhibitions, and referrals can be goldmines. Evaluate their expertise, production capabilities, and adherence to quality standards.

Once potential suppliers are identified, assessing their competence is critical. This involves a multi-dimensional evaluation:

Quality Standards: Assess certifications (ISO, AS9100, etc.) and quality control processes. Look for reliability and consistency in delivering high-quality components.

Capacity and Scalability: Analyze production capacity to ensure the supplier can meet your current and future demands. Scalability is crucial for long-term partnerships.

Technology and Innovation: Consider suppliers who embrace innovation and modern manufacturing techniques. Those leveraging advancements like additive manufacturing or AI-driven quality control may offer a competitive edge.

Crafting a robust supply chain hinges on selecting suppliers aligned with your standards. Develop a scoring matrix considering critical factors like:

Quality Assurance: Rate suppliers based on product quality, adherence to specifications, and defect rates.

Reliability and Timeliness: Evaluate on-time delivery performance and their ability to meet deadlines consistently.

Cost and Value: Consider pricing structures while also weighing in additional value-added services, such as post-processing, technical support, and inventory management.

By assigning weightage to each metric, you can objectively compare suppliers and make informed decisions.

Establishing clear communication channels and fostering a collaborative relationship with chosen suppliers is paramount. Clearly outline expectations, maintain open dialogue, and provide constructive feedback. This facilitates smoother operations, fosters innovation, and strengthens partnerships for mutual growth.

Enter Richconn, a bastion of precision engineering, renowned for its commitment to excellence and reliability in crafting precision components. With a heritage steeped in innovation and a track record of delivering high-quality solutions, Richconn stands as a beacon in the realm of precision manufacturing.

Richconn’s forte lies in its diverse expertise across multiple industries. From aerospace to medical devices and automotive applications, Richconn caters to a spectrum of needs, offering an array of precision components designed to surpass industry standards.

The company’s comprehensive services encompass:

Consultative Approach: Collaborating closely with clients to understand specific needs and customize solutions accordingly.

Advanced Manufacturing Technologies: Leveraging cutting-edge CNC machining and innovative manufacturing techniques to ensure precision and consistency.

Quality Assurance: Stringent quality control measures at every stage to guarantee components that meet stringent specifications.

Choosing Richconn as a precision components partner offers a myriad of advantages:

Reliability and Consistency: Richconn’s commitment to quality ensures consistent delivery of precision components meeting exacting standards.

Customization and Flexibility: Tailoring solutions to match unique client requirements, offering flexibility in designs, materials, and production volumes.

Innovation and Scalability: Embracing technological advancements to drive innovation, ensuring scalability to meet evolving industry demands.

Richconn's ethos revolves around fostering collaborative partnerships with clients. By delving deep into understanding client needs, Richconn aligns its expertise and resources to deliver not just components but comprehensive solutions that fuel client success stories.

The company's dedication to continuous improvement and innovation ensures clients stay ahead in their respective industries, propelling them towards excellence.

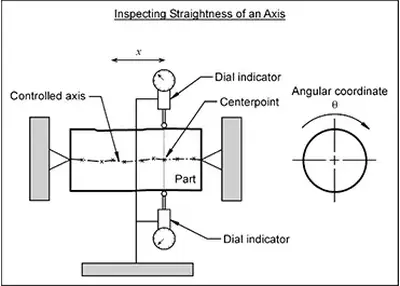

Understanding Straightness: Unveiling Precision in EngineeringNovember 21, 2023Welcome to a journey through the realm of straightness—a fundamental concept in the world of engineering and precision manufacturing. Ever wondered how straightness impacts the quality of products or the efficiency of industrial processes? Join me as we explore the nuances and practical applications of this crucial element.view

Understanding Straightness: Unveiling Precision in EngineeringNovember 21, 2023Welcome to a journey through the realm of straightness—a fundamental concept in the world of engineering and precision manufacturing. Ever wondered how straightness impacts the quality of products or the efficiency of industrial processes? Join me as we explore the nuances and practical applications of this crucial element.view Dual-tone Baking Paint Technology: Achieving Unique Visual EffectsJuly 31, 2023Have you seen two-tone colored cars, phones, appliances, buildings? Want to understand how to achieve two-tone baked paint? This article introduces this unique parts painting technique in detail, expl...view

Dual-tone Baking Paint Technology: Achieving Unique Visual EffectsJuly 31, 2023Have you seen two-tone colored cars, phones, appliances, buildings? Want to understand how to achieve two-tone baked paint? This article introduces this unique parts painting technique in detail, expl...view Cast Iron vs Steel: Which One to Choose for Your CNC Project?January 15, 2024Cast iron vs steel is one of the many comparisons common among manufacturers. What are the differences between them? Read on and you can get the answer.view

Cast Iron vs Steel: Which One to Choose for Your CNC Project?January 15, 2024Cast iron vs steel is one of the many comparisons common among manufacturers. What are the differences between them? Read on and you can get the answer.view How to Reduce CNC CostsOctober 16, 2023In CNC machining, there are advances and improvements year after year. As a result, it is also becoming more complex. Consequently, it's also becoming more difficult to decide what to consider whe...view

How to Reduce CNC CostsOctober 16, 2023In CNC machining, there are advances and improvements year after year. As a result, it is also becoming more complex. Consequently, it's also becoming more difficult to decide what to consider whe...view How to Measure Surface Roughness?August 2, 2023In order to ensure the optimal quality of parts, the surface of components after manufacturing applications must be maintained within the desired range of roughness. Surface treatment plays a critical...view

How to Measure Surface Roughness?August 2, 2023In order to ensure the optimal quality of parts, the surface of components after manufacturing applications must be maintained within the desired range of roughness. Surface treatment plays a critical...view What is Black Oxide? A Guide on Black Oxide Coating 2023September 5, 2023While there are indeed numerous surface finish types available for manufacturers to choose from, the black oxide coating is a popular choice for many. The black oxide coating offers a combination of v...view

What is Black Oxide? A Guide on Black Oxide Coating 2023September 5, 2023While there are indeed numerous surface finish types available for manufacturers to choose from, the black oxide coating is a popular choice for many. The black oxide coating offers a combination of v...view

EN

EN

ru

ru