At Richconn, you can easily add threaded holes to your CNC machined parts. Adding by turning gives you many additional threading options. There are two types when it comes to threading: Internal threads and external threads.

Internal threads are machined with a single-flute tool rather than a traditional threading tool. For parts with core holes that require internal threads, the actual threads must be removed from the CAD model, leaving only the core hole diameter. Our engineers recognizes a hole to be threaded if it:

* falls within the diameter range for the desired thread, and

* for the milling process on one of the three main axes or

* is perpendicular to the axis of rotation for the turning process.

Richconn supports right-hand threaded holes on machined parts for UNC and UNF threads between N 2 and 1/2 inch; metric threads from M2 to M12 are also available. Due to their intended position and manufacturing method, some threads may not be able to be executed.

The maximum depths for threads specified by our threading tools are another critical factor that must be considered. Our #2 threads have a maximum thread depth of 5.1mm, measured from the top of surrounding features. With a thread depth of up to 25.4mm, our 1/2-inch threads can be cut much deeper. For metric threads, thread depths from 5.1 mm to 25.4 mm are possible. The thread depths that can be produced increase gradually as the thread diameter increases. You can find out more about this below in the design tip.

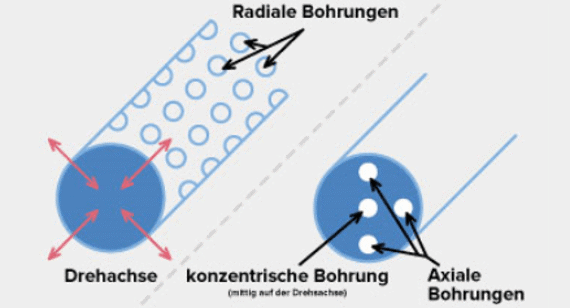

Internal threads are also available for turned parts. Many of the rules also apply to machining threads with driven tools on a lathe. However, the range of threads that can be produced is more limited here than with the milling process. UNC and UNF threads range from N 4-40 to 1/2-20, metric threads from M3 to M10. Since adding driven tools to our capacity, we are able to produce bores radially, axially and on axis. This has an effect on thread cutting, as some threads are only available lying on the axis. Please pay close attention to your quote or contact a customer service representative if further clarification is needed.

The illustrations show three different types of bores that are possible for CNC turned parts.

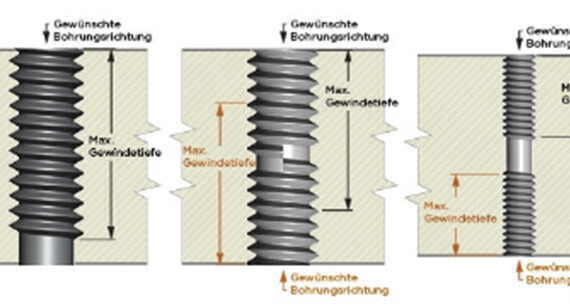

When machining internally threaded holes, a hole can often be longer than can be reached by our threading tools. In this case, there are a few options available depending on your needs.

* For a long through hole that exceeds the maximum reach, select the side from which the screw is expected to be threaded, as shown in Figure 1. If your screw is expected to run all the way through the part, a tap will also need to be run through the hole (in a finishing step) to complete the thread.

From left to right, Figures 1, 2 and 3 show three methods for dealing with maximum thread depths.

* You can also thread the feature from both sides, as shown in Figure 2. Note, however, that the maximum thread depths overlap in the hole. When features are threaded from both sides, there is a risk that the threads will tilt and a screw may not thread completely and cleanly through the part. But as long as the threads do not overlap as shown in Figure 3, there is usually nothing wrong with selecting tapped holes from both sides.

With the introduction of lathes, the options for making external threads increased. You can now get external threads for selected sizes, provided your parts are suitable for the turning process. We use a special threading tool with a specific number of thread sizes, depths and positions within the part geometry. However, Richconn's modern turning process provides external threads on the center axis of the part as well as driven tools that can thread holes as long as they follow similar guidelines to milling. The process can produce not only on-axis holes, but also axial and radial holes.

As with internal threads, designing external threads on turned parts requires removing the thread from the CAD model so our software can recognize it. Also, when designing external threads, you should use the milling process as a guide, not the turning process. After you receive your quote for the turning process, you can select the appropriate thread size.

Although milled external threads are used on parts much less frequently than internal threads, they can be machined effectively. Milled external threads are made over half the diameter. The part is then rotated 180 degrees so that the opposite threads can be machined in the same manner. This works well for larger, coarser external threads. We are able to produce high quality 1/2 inch threads. However, you may want to re-tap the threads to remove any material debris or misalignment because the threads are made using two different machining processes.

The CAD model shows a view of the milled external thread, with the resulting radii highlighted in yellow. This only applies to cnc milling parts.

Smaller external threads such as N 6-32UNC are much more difficult to produce with a ball and end mill, since a larger radius would result at the root of the thread due to the thread pitch being too small. You would have to recut the threads in this case with a die to remove the material residue. For many parts, a radius of 0.2 mm to 0.4 mm would remain.

If you need stronger threads, wire thread inserts are also available. Coil insert threads are used for holes. However, wire inserts are not used during manufacturing. The inserts must be installed by the user after fabrication, but before the parts are assembled. Coil inserts are available for UNC and UNF threads between N 2 and 1/2 inch and for metric threads between M2 and M12 with the same depths as standard tapped holes. Richconn is optimized for HeliCoil brand inserts and supports standard sizes and lengths.

Since there are no uniform standards between CAD programs in terms of specifying threads, our automated system determines where threads can be placed, looking for suitable potential diameters. Avoid modeling threads on parts. We recommend selecting the core hole diameter as long as it is approximately 75 percent of the thread diameter in the design.

CAD files should be submitted in a file format other than STL. Of course, you can also upload CNC machining part files in STL format, and our engineers can identify features in multiple formats.

For milled parts that require external threads, you will need to design the threads on your part as our standard milling process uses ball and end mills. As mentioned earlier, this would not be the preferred method for producing threads as it would require secondary machining to re-tap the threads with a die to ensure proper assembly of the parts.

Turned parts are much better at producing external threads because the part is center turned and a sharp single-edged threading tool can produce a high-quality thread. The design of a turned external thread is similar to the internal hole. You will need to remove the threads so the software can digitally detect the outside diameter to determine the type of thread you need.

Within your Richconn quotation, you have the option to select internal and external threads in the part characteristics. On the Thread Mapping tab of your quote, you will see a fully interactive model where you can select the available thread features. Each selectable feature is highlighted and you can manually select threads. You can also assign multiple threads at once in UNC, UNF, and metric sizes, which can be faster than assigning threads to individual holes. However, be careful not to accidentally assign threads to holes that should not receive threads.

Richconn offers threads for milled parts made of plastic and metal. For turned parts, threads are currently only available for metals. In conjunction with coil inserts, we offer UNC, UNF, and metric threads (however, we do not provide or install coil inserts). For a complete list of threading guidelines for milled and turned parts, click here. If you have any questions, please feel free to contact our technical support staff at sales@richconn.com.cn or +86-0755-28025755.

Applications of CNC Machining in Automotive IndustryJune 14, 2024As we know, CNC machining is widely used in automotive manufacturing. What is the specific application of CNC machining in the field of automotive manufacturing? Here come the answers!view

Applications of CNC Machining in Automotive IndustryJune 14, 2024As we know, CNC machining is widely used in automotive manufacturing. What is the specific application of CNC machining in the field of automotive manufacturing? Here come the answers!view Luxury carbon fiber: NTPTTM ultra-high performance prepreg carbon fiber full resolutionSeptember 25, 2023With the improvement of people's living standards, the luxury market is booming. Many luxury goods use specialized high-tech materials in their design and manufacturing processes to ensure that th...view

Luxury carbon fiber: NTPTTM ultra-high performance prepreg carbon fiber full resolutionSeptember 25, 2023With the improvement of people's living standards, the luxury market is booming. Many luxury goods use specialized high-tech materials in their design and manufacturing processes to ensure that th...view How to choose the right material for cnc cnc machining parts?November 1, 2023In the field of CNC numerical control machining, the correct selection of suitable materials is crucial to the performance, accuracy and durability of parts. Different environments and application scenarios require different types of materials, and the following will analyze how to choose the right material from several aspects.view

How to choose the right material for cnc cnc machining parts?November 1, 2023In the field of CNC numerical control machining, the correct selection of suitable materials is crucial to the performance, accuracy and durability of parts. Different environments and application scenarios require different types of materials, and the following will analyze how to choose the right material from several aspects.view 5 Bending and Forming Methods for Sheet MetalDecember 4, 2023Sheet metal refers to a process used to manufacture a variety of metal products, which involves processing sheet metal into the desired shape and size by cutting, stamping, bending, and welding.view

5 Bending and Forming Methods for Sheet MetalDecember 4, 2023Sheet metal refers to a process used to manufacture a variety of metal products, which involves processing sheet metal into the desired shape and size by cutting, stamping, bending, and welding.view 18-8 Stainless Steel vs 304: What's the Difference and Which One to Choose?December 7, 2023Stainless steel is one of the most widely used materials in the world, thanks to its excellent properties, such as corrosion resistance, strength, durability, and aesthetics. However, not all stainless steel grades are the same.view

18-8 Stainless Steel vs 304: What's the Difference and Which One to Choose?December 7, 2023Stainless steel is one of the most widely used materials in the world, thanks to its excellent properties, such as corrosion resistance, strength, durability, and aesthetics. However, not all stainless steel grades are the same.view Surface Finish 101: An Overview of Plastic Surface Finish ChartSeptember 5, 2023A process that involves the use of a machine to impose characteristic irregularities on the surface of its product. Constant use tends to cause the product to wear down over time. This is usually due ...view

Surface Finish 101: An Overview of Plastic Surface Finish ChartSeptember 5, 2023A process that involves the use of a machine to impose characteristic irregularities on the surface of its product. Constant use tends to cause the product to wear down over time. This is usually due ...view

EN

EN

ru

ru