For CNC machining of parts with multiple and complex surfaces, the sequence of CNC machining, heat treatment, and auxiliary processes should be arranged reasonably, and the connection between processes should be resolved. Before clamping the raw material, measure whether the size of the blank meets the drawing requirements, and carefully check whether its placement is consistent with the programming instructions. In medical CNC machining, self-inspection should be performed in a timely manner after rough machining is completed, so as to adjust the error data in time.

Whether the mechanical parts are loose during the machining process;

Whether the processing technology of medical parts is correctly aligned with the starting point;

Whether the size of the CNC medical machining part to the benchmark edge (reference point) meets the drawing requirements;

The position and size of medical parts. After checking the position and size, the shape and size of the rough machining (except for arcs) need to be measured.

Medical parts should be finely machined after confirmation of rough machining. Before the precise machining of medical parts, self-inspection of the shape and size of the drawing parts should be carried out: check the length and width dimensions of the vertical surface machining position; measure the base point size marked on the drawing of the inclined surface machining position. After completing the self-inspection of the parts and confirming that they meet the requirements of the drawing and process, the workpiece can be taken out and sent to the inspector for special inspection. When medical parts are produced in small batches, batch processing should be carried out after confirming the first piece is qualified. What are the specific requirements for medical CNC machining parts?

Reliability and high quality are the top priorities of medical CNC machining, so the medical device industry has put forward new requirements for professional precision cutting tools. Difficult-to-machine materials, complex workpiece shapes, and frequent CNC small-batch production require very high requirements for cutting tools used to process professional medical devices. The main manifestations are:

Advanced medical device machining equipment such as automatic lathes, multi-spindle machine tools, and rotary worktables are completely different from the machining centres and lathes saws. Their size is very small and the structure is very compact. In response to such requirements, the structure of the cutting tool also needs to be specially designed, and the size of the cutting tool also needs to be small, while ensuring the rigidity of the cutting tool.

For medical devices, the most important thing is the efficiency of medical CNC machining services, that is, the machining cycle time, which requires the ability to replace the blade in the shortest possible time.

The workpiece itself, it is very different from other mechanical parts. The medical devices implanted in the human body first require good smoothness, high accuracy, and no deviation, which requires that the design of the cutting tool from the structure of the cutting blade to the design of the cutting blade coating must meet very high processing requirements.

Micron-scale tolerances are very common in the medical industry, and choosing the right cutting tool requires keen insight and rich experience. On the one hand, even drilling small holes requires the use of lubricants to reduce friction, reliably dissipate heat, and treat fine iron chips at the cutting edge; on the other hand, when producing cutting-edge medical devices (without burrs), it is necessary to use sharp and stable cutting tools to obtain high-quality surfaces.

As a professional CNC China company, Richconn provides quality OEM precision CNC machining solutions for your medical needs. Feel free to send us your requirements.

Unveiling the Precision World of Machined Gears: A Richconn PerspectiveNovember 10, 2023In the intricate tapestry of mechanical engineering, machined gears stand as the unsung heroes, translating rotational motion with unparalleled precision. These gears are meticulously crafted to meet the demanding requirements of various industries, ensuring seamless operation in complex machinery.view

Unveiling the Precision World of Machined Gears: A Richconn PerspectiveNovember 10, 2023In the intricate tapestry of mechanical engineering, machined gears stand as the unsung heroes, translating rotational motion with unparalleled precision. These gears are meticulously crafted to meet the demanding requirements of various industries, ensuring seamless operation in complex machinery.view CNC Machined Bicycle Parts: Elevate Your Cycling Experience with Richconn PrecisionNovember 13, 2023In the realm of cycling, precision matters. Every curve, every gear, and every component plays a crucial role in enhancing the rider's experience. That's where Richconn comes in – a name synonymous with excellence in CNC machining for bicycle parts.view

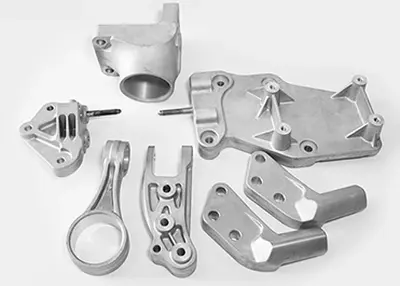

CNC Machined Bicycle Parts: Elevate Your Cycling Experience with Richconn PrecisionNovember 13, 2023In the realm of cycling, precision matters. Every curve, every gear, and every component plays a crucial role in enhancing the rider's experience. That's where Richconn comes in – a name synonymous with excellence in CNC machining for bicycle parts.view What Are the Advantages of Cast Aluminum PartsOctober 19, 2023The continuous development of society, people's lives are increasingly high demand for aluminum casting process is also increasing in demand. In our use and use of aluminum casting process, do we understand the aluminum casting production out of aluminum die casting parts have what advantages?view

What Are the Advantages of Cast Aluminum PartsOctober 19, 2023The continuous development of society, people's lives are increasingly high demand for aluminum casting process is also increasing in demand. In our use and use of aluminum casting process, do we understand the aluminum casting production out of aluminum die casting parts have what advantages?view Richconn 2024 Chinese New Year Holiday NoticeJanuary 2, 2024January 02, 2024Chinese New Year is approaching! We would like to remind you that Richconn will be on holiday to celebrate our Chinese New Year. For your convenience in arranging your project, please ...view

Richconn 2024 Chinese New Year Holiday NoticeJanuary 2, 2024January 02, 2024Chinese New Year is approaching! We would like to remind you that Richconn will be on holiday to celebrate our Chinese New Year. For your convenience in arranging your project, please ...view Surface Finish 101: An Overview of Plastic Surface Finish ChartSeptember 5, 2023A process that involves the use of a machine to impose characteristic irregularities on the surface of its product. Constant use tends to cause the product to wear down over time. This is usually due ...view

Surface Finish 101: An Overview of Plastic Surface Finish ChartSeptember 5, 2023A process that involves the use of a machine to impose characteristic irregularities on the surface of its product. Constant use tends to cause the product to wear down over time. This is usually due ...view What Are Tolerances? How Are Tolerances Determined When Designing Machinery?October 26, 2023Tolerance is precise machining and design, the actual parameter values of the parts of the allowable amount of change, such as a certain part of the upper and lower limits were 100, 60, then its tolerance is 40; if the upper and lower limits were +100, -100, then its tolerance is 200.view

What Are Tolerances? How Are Tolerances Determined When Designing Machinery?October 26, 2023Tolerance is precise machining and design, the actual parameter values of the parts of the allowable amount of change, such as a certain part of the upper and lower limits were 100, 60, then its tolerance is 40; if the upper and lower limits were +100, -100, then its tolerance is 200.view

EN

EN

ru

ru