In the preparation of CNC machining programs, proper use of methods and techniques is of great significance to ensure and improve the machining accuracy of CNC machine tools. So what determines the machining accuracy of CNC services?

The position detection element is composed of detection elements (sensors) and signal processing devices, and is an important part of the closed-loop servo system of CNC machine tools. Its function is to detect the actual value of the position and speed of the workbench, and send a feedback signal to the numerical control device or servo device, thus forming a closed-loop control. The detection element generally uses the principle of light or magnetism to complete the detection of position or speed.

The position detection element is divided into direct measurement element and indirect measurement element according to the detection method. Linear detection elements are generally used for linear movement measurement of the machine tool, which is called direct measurement, and the formed position closed-loop control is called fully closed-loop control. The measurement accuracy mainly depends on the accuracy of the measuring element and is not affected by the transmission accuracy of the machine tool.

Since the linear displacement of the aluminium CNC service machine tool table has an accurate proportional relationship with the rotation angle of the driving motor, the method of driving the detection motor or the rotation angle of the screw can be used to indirectly measure the moving distance of the table. This method is called indirect measurement. The formed position closed-loop control is called semi-closed-loop control.

The machining accuracy of the closed-loop CNC machine tool is largely determined by the accuracy of the position detection device, and the service CNC machine tools materials has very strict requirements on the position detection element. Compared with the numerical control device, the probability of failure of the detection element is still relatively high, and the phenomenon of cable damage, component contamination, and collision deformation often occurs.

If it is suspected that the detection element is faulty, first check whether the cable is broken, stained, deformed, etc., and can also determine the quality of the detection element by measuring its output, which requires mastering the working principle of the detection element and the output signal. . The following is an example to illustrate, for example, what should be done when the detection device malfunctions and the mechanical oscillation (during acceleration/deceleration)?

(1) The pulse encoder is faulty. At this time, check whether the voltage of the feedback line terminal on the speed unit drops at a certain point. If the voltage drops, it indicates that the pulse encoder is defective, and the encoder should be replaced.

(2) The cross coupling of the pulse encoder may be damaged, causing the shaft speed to be out of sync with the detected speed, and the coupling should be replaced.

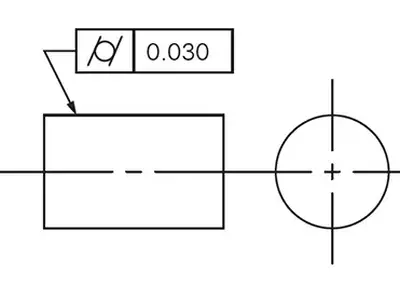

Unlocking Precision: Mastering Cylindricity for Engineering ExcellenceNovember 21, 2023In the intricate world of engineering, precision reigns supreme. Enter the realm of cylindricity - a fundamental attribute dictating the perfection of cylindrical forms. Here, I guide you through an explorative journey, unveiling the essence of cylindricity, its nuanced applications in GD&T (Geometric Dimensioning and Tolerancing), and the crucial methods to measure and comprehend this vital parameter.view

Unlocking Precision: Mastering Cylindricity for Engineering ExcellenceNovember 21, 2023In the intricate world of engineering, precision reigns supreme. Enter the realm of cylindricity - a fundamental attribute dictating the perfection of cylindrical forms. Here, I guide you through an explorative journey, unveiling the essence of cylindricity, its nuanced applications in GD&T (Geometric Dimensioning and Tolerancing), and the crucial methods to measure and comprehend this vital parameter.view Electrophoresis Metal Coating: Enhancing Analytical Chemistry ApplicationsFebruary 29, 2024Analytical chemistry is a branch of chemistry that deals with the identification and quantification of chemical compounds. Electrophoresis is a technique commonly used in analytical chemistry to separ...view

Electrophoresis Metal Coating: Enhancing Analytical Chemistry ApplicationsFebruary 29, 2024Analytical chemistry is a branch of chemistry that deals with the identification and quantification of chemical compounds. Electrophoresis is a technique commonly used in analytical chemistry to separ...view Precautions for Stamping Dies 1July 11, 2023Spring compression and calculationIn a set of stamping dies, more elastic materials need to be used, including springs of different specifications, urethane, nitrogen springs, etc., and different elas...view

Precautions for Stamping Dies 1July 11, 2023Spring compression and calculationIn a set of stamping dies, more elastic materials need to be used, including springs of different specifications, urethane, nitrogen springs, etc., and different elas...view CNC POR: Demystifying the Key Technology in CNC MachiningNovember 2, 2023In the world of precision engineering and manufacturing, CNC technology plays a pivotal role. Among the various CNC techniques, CNC POR stands out as a critical component, offering unmatched precision, efficiency, and versatility.view

CNC POR: Demystifying the Key Technology in CNC MachiningNovember 2, 2023In the world of precision engineering and manufacturing, CNC technology plays a pivotal role. Among the various CNC techniques, CNC POR stands out as a critical component, offering unmatched precision, efficiency, and versatility.view Hot Rolled vs Cold Rolled: Which One Is Right for Your Project?February 26, 2024To optimize the properties of steel for specific applications, it is necessary to consider factors beyond its chemical composition. Hot rolling or cold rolling is a process employed to enhance the sha...view

Hot Rolled vs Cold Rolled: Which One Is Right for Your Project?February 26, 2024To optimize the properties of steel for specific applications, it is necessary to consider factors beyond its chemical composition. Hot rolling or cold rolling is a process employed to enhance the sha...view CNC Machined Motorcycle Parts: Precision Craftsmanship by RichconnNovember 14, 2023Rev up your expectations as we delve into the intricate world of CNC machined motorcycle parts. I'm excited to guide you through the details, showcasing how Richconn is your go-to source for precision solutions. Let's ride into the comprehensive exploration!view

CNC Machined Motorcycle Parts: Precision Craftsmanship by RichconnNovember 14, 2023Rev up your expectations as we delve into the intricate world of CNC machined motorcycle parts. I'm excited to guide you through the details, showcasing how Richconn is your go-to source for precision solutions. Let's ride into the comprehensive exploration!view

EN

EN

ru

ru