In today's competitive market, every business is constantly finding ways to cut costs without compromising the quality of their products or services. When it comes to CNC machining, one of the most effective strategies is to find affordable materials that still meet the required specifications. In this blog post, we will explore some of the best cheap CNC material options that can help you reduce expenses while maintaining superior quality.

In the world of CNC machining, the cost of materials plays a significant role in determining the feasibility of a project. While high-quality materials are essential for precision and durability, they often come with a hefty price tag. However, with the right knowledge, businesses can find cheap CNC material alternatives that offer similar qualities at a fraction of the cost.

When it comes to affordable CNC materials, there are several options that businesses can consider. One popular choice is plywood, which is not only cost-effective but also versatile and readily available. Plywood CNC cutouts can be used in a wide range of applications such as signage, furniture, and prototypes.

Another inexpensive option is medium-density fiberboard (MDF). MDF is known for its stability, smooth finish, and low cost compared to solid wood. It is an ideal choice for projects that require intricate designs or intricate detailing, such as decorative items or custom cabinetry.

Additionally, there are various types of plastics that provide excellent cost-effectiveness while offering durability and versatility. Acrylic, for example, is a widely used plastic material that can be CNC machined into complex shapes and is commonly used in signage, automotive parts, and point-of-sale displays.

While finding cheap CNC materials is crucial to cutting costs, it is equally important to strike a balance between affordability and quality. Here are a few tips to help you make the right choice:

Evaluate the project requirements: Determine the specific characteristics and performance criteria that your project demands, such as strength, durability, or resistance to certain environments. This will help you select the appropriate cheap CNC material that fulfills these requirements without breaking your budget.

Consider secondary processes: Sometimes, cheaper materials might require additional finishing processes to achieve the desired look or functionality. Take into account the costs of any post-machining treatments, such as painting, coating, or sealing, when calculating the overall cost of the project.

Partner with a trusted supplier: Working with a reputable supplier who understands your cost-saving goals and can guide you in selecting the best cheap CNC material is essential. They can provide expert advice and recommend materials that meet both your financial and quality requirements.

Cutting costs in CNC machining without compromising quality is a challenge faced by many businesses. By exploring the wide range of cheap CNC material options available and following the tips mentioned above, you can successfully reduce expenses while maintaining superior quality in your projects. Remember, it's all about finding the right balance between affordability and the desired performance characteristics.

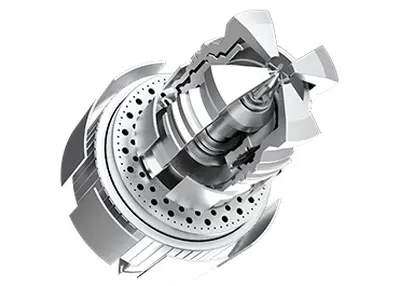

Unleashing Precision: Richconn's CNC Machined Steel ExcellenceNovember 10, 2023Welcome to the realm of precision and durability, where machined steel takes center stage. In this comprehensive exploration, we'll navigate through the intricacies of machined steel, unveil its diverse applications, compare various types, delve into performance metrics, examine Richconn's CNC machining advantages, and provide essential knowledge on mechanical machining.view

Unleashing Precision: Richconn's CNC Machined Steel ExcellenceNovember 10, 2023Welcome to the realm of precision and durability, where machined steel takes center stage. In this comprehensive exploration, we'll navigate through the intricacies of machined steel, unveil its diverse applications, compare various types, delve into performance metrics, examine Richconn's CNC machining advantages, and provide essential knowledge on mechanical machining.view Galvanized vs. Galvannealed Steel: A ComparisonNovember 28, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. However, steel is also susceptible to corrosion and rust when exposed to moisture and oxygen.view

Galvanized vs. Galvannealed Steel: A ComparisonNovember 28, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. However, steel is also susceptible to corrosion and rust when exposed to moisture and oxygen.view Flexible CNC Lead Times - Save Money with Longer Lead TimesOctober 12, 2023From now on, you have the flexibility to choose your CNC delivery times and thus determine your own delivery dates and costs for your CNC parts. As part of the Flexible Manufacturing option, our lead times of 6 to 12 days offer you a lower price - and you'll still receive your parts faster than most other suppliers.view

Flexible CNC Lead Times - Save Money with Longer Lead TimesOctober 12, 2023From now on, you have the flexibility to choose your CNC delivery times and thus determine your own delivery dates and costs for your CNC parts. As part of the Flexible Manufacturing option, our lead times of 6 to 12 days offer you a lower price - and you'll still receive your parts faster than most other suppliers.view Aluminum Alloy Anodic Oxidation Common ProblemsOctober 23, 2023Anodizing is one of the most common metal surface treatment operations performed on aluminum parts. It is an electrochemical process that involves immersing aluminum parts in a series of tanks to transform the aluminum surface into a durable and corrosion-resistant finish.view

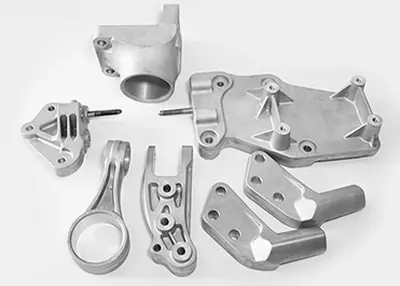

Aluminum Alloy Anodic Oxidation Common ProblemsOctober 23, 2023Anodizing is one of the most common metal surface treatment operations performed on aluminum parts. It is an electrochemical process that involves immersing aluminum parts in a series of tanks to transform the aluminum surface into a durable and corrosion-resistant finish.view Precision Components: Unveiling Excellence in CNC ManufacturingNovember 17, 2023In the realm of precision engineering, where intricacy meets innovation, the quest for superior precision components drives industries forward. At Richconn, we don't just craft components; we sculpt reliability and precision. Prepare to delve deep into the world of precision components with us, discovering the nuances, intricacies, and pathways to excellence.view

Precision Components: Unveiling Excellence in CNC ManufacturingNovember 17, 2023In the realm of precision engineering, where intricacy meets innovation, the quest for superior precision components drives industries forward. At Richconn, we don't just craft components; we sculpt reliability and precision. Prepare to delve deep into the world of precision components with us, discovering the nuances, intricacies, and pathways to excellence.view Revolutionizing Automotive Manufacturing with CNC Cutting Aluminum SheetsFebruary 29, 2024The Rise of CNC Cutting in Automotive ManufacturingIn the fast-paced world of automotive manufacturing, precision and efficiency are key factors that can make or break a company's success. One tec...view

Revolutionizing Automotive Manufacturing with CNC Cutting Aluminum SheetsFebruary 29, 2024The Rise of CNC Cutting in Automotive ManufacturingIn the fast-paced world of automotive manufacturing, precision and efficiency are key factors that can make or break a company's success. One tec...view

EN

EN

ru

ru