In the world of healthcare equipment, precision and durability are of the utmost importance. From monitoring devices to surgical tools, every piece of equipment must be able to withstand the demanding requirements of the healthcare industry. This is where CNC powder coating comes into play, offering a reliable and efficient solution for enhancing the performance and longevity of healthcare equipment.

CNC powder coating is a process that involves applying a dry powder material to a surface and then curing it with heat to create a durable and protective finish. This type of coating is commonly used in industries such as automotive, aerospace, and healthcare, thanks to its superior adhesion, corrosion resistance, and overall durability. With CNC precision technology, the powder is applied with high accuracy and consistency, ensuring a uniform coating that meets the exact specifications of the healthcare equipment.

One of the key advantages of CNC powder coating in healthcare equipment applications is its ability to provide a protective barrier against corrosion, chemicals, and wear. This is particularly important in healthcare settings where equipment is exposed to harsh cleaning agents and frequent use. By adding a durable powder coating, healthcare equipment can maintain its appearance and functionality for a longer period, ultimately reducing the need for costly repairs or replacements.

In addition, CNC powder coating offers flexibility in terms of color and finish options, allowing healthcare facilities to customize their equipment to match their branding or aesthetic preferences. This versatility is particularly valuable in settings such as hospitals and clinics, where the appearance of equipment can contribute to a positive patient experience.

CNC powder coating can be used in a wide range of healthcare equipment applications, including medical devices, surgical instruments, hospital furniture, and diagnostic tools. For example, surgical instruments often require a protective coating to prevent corrosion and maintain sharpness, while hospital furniture such as bed frames and IV stands can benefit from a durable finish that withstands frequent cleaning and handling.

In medical device manufacturing, CNC powder coating is commonly used to enhance the durability and performance of devices such as monitoring systems, imaging equipment, and laboratory instruments. By adding a protective coating, manufacturers can ensure that their products meet the stringent requirements of the healthcare industry and provide reliable performance for healthcare professionals and patients.

When incorporating CNC powder coating into healthcare equipment applications, it is essential to partner with a reputable and experienced coating provider. Look for a company that specializes in healthcare equipment coatings and has a track record of delivering high-quality results. Additionally, consider factors such as turnaround time, pricing, and customer service to ensure a smooth and successful coating process.

By choosing the right CNC powder coating partner, healthcare facilities can enhance the performance and longevity of their equipment, ultimately improving patient care and operational efficiency. With the benefits of CNC precision technology and durable powder coating, healthcare equipment can withstand the demanding requirements of the healthcare industry and deliver reliable performance for years to come.

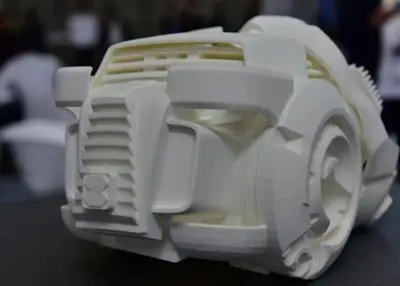

The Ultimate 3D Printing Guide: Types of 3D Printers, Materials & MoreApril 17, 2024Here is an ultimate guide to 3D printing technology, including types of 3D printers, materials, and more. Read on and choose the right one for your project.view

The Ultimate 3D Printing Guide: Types of 3D Printers, Materials & MoreApril 17, 2024Here is an ultimate guide to 3D printing technology, including types of 3D printers, materials, and more. Read on and choose the right one for your project.view How to Find the Right Manufacturing PartnerOctober 13, 2023It’s worth taking the time to find a supplier that’s a perfect fit for the buyer’s company. Think of it as a partnership in which both parties are committed and invested. In the digital age, it is increasingly advisable to also consider additional total cost of ownership (TCO) savings.view

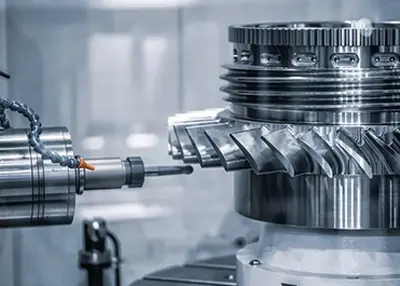

How to Find the Right Manufacturing PartnerOctober 13, 2023It’s worth taking the time to find a supplier that’s a perfect fit for the buyer’s company. Think of it as a partnership in which both parties are committed and invested. In the digital age, it is increasingly advisable to also consider additional total cost of ownership (TCO) savings.view Importance Of CNC Machining In Manufacturing Different PartsOctober 24, 2023CNC machining services help you to manufacture and fabricate different parts of metal as per the requirements. This process also helps in creating tolerances for various materials and metal parts. This process is usually a subtractive method of producing metal parts.view

Importance Of CNC Machining In Manufacturing Different PartsOctober 24, 2023CNC machining services help you to manufacture and fabricate different parts of metal as per the requirements. This process also helps in creating tolerances for various materials and metal parts. This process is usually a subtractive method of producing metal parts.view How to Remove Chrome Plating Easily? (A Complete Guide 2024)March 11, 2024Learn how to remove chrome plating effectively with our comprehensive guide and get expert tips for successfully stripping chrome from metal surfaces.view

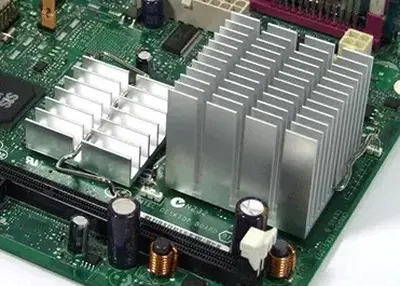

How to Remove Chrome Plating Easily? (A Complete Guide 2024)March 11, 2024Learn how to remove chrome plating effectively with our comprehensive guide and get expert tips for successfully stripping chrome from metal surfaces.view Heat Sinks: What They Are, How They Work, and How to Design ThemDecember 8, 2023Have you ever wondered how your laptop, smartphone, or gaming console can run so fast without overheating? The answer is heat sinks. Heat sinks are devices that help to cool down electronic components by transferring heat away from them. They are essential for ensuring the reliability and performance of many modern devices.view

Heat Sinks: What They Are, How They Work, and How to Design ThemDecember 8, 2023Have you ever wondered how your laptop, smartphone, or gaming console can run so fast without overheating? The answer is heat sinks. Heat sinks are devices that help to cool down electronic components by transferring heat away from them. They are essential for ensuring the reliability and performance of many modern devices.view Choosing the Optimal Material For CNC Machining.October 17, 2023If you find the vast selection of different materials for CNC machining confusing, this blog will tell you how to reduce that number to a manageable level.

Choosing the right material for CNC machining can make all the difference in getting a working part or prototype made at a reasonable price.view

Choosing the Optimal Material For CNC Machining.October 17, 2023If you find the vast selection of different materials for CNC machining confusing, this blog will tell you how to reduce that number to a manageable level.

Choosing the right material for CNC machining can make all the difference in getting a working part or prototype made at a reasonable price.view

EN

EN

ru

ru