In the world of automotive manufacturing, precision and reliability are crucial for the smooth operation of gear systems. As technology advances, the demand for precision components in the automotive industry has led to the increasing use of CNC automotive parts. This blog explores the unrivaled precision offered by CNC automotive parts and its impact on the performance and efficiency of gear systems.

CNC, which stands for Computer Numerical Control, refers to the process of using computerized machinery to precisely control the movement of tools that shape and form automotive components. CNC automotive parts are manufactured by computer-controlled machines, which guarantee consistent and accurate production of intricate components. This enables gear systems to operate seamlessly, reducing friction and wear.

The precision offered by CNC automotive parts significantly enhances the performance and durability of gear systems. These parts are manufactured to extremely tight tolerances, ensuring that each component fits perfectly within the system. This level of accuracy minimizes backlash, reduces noise, and optimizes power transmission efficiency. As a result, vehicles equipped with CNC automotive parts experience improved fuel efficiency, smoother shifting, and reduced maintenance requirements.

CNC automotive parts allow for a high degree of customization and flexibility in gear system design. With the ability to program the CNC machines, manufacturers can create complex shapes and sizes, ensuring a perfect fit within unique gear configurations. This adaptability is essential in the ever-evolving automotive industry, where various gear systems tailored to different vehicles and applications are required. CNC technology enables automotive manufacturers to easily adapt and optimize gear systems according to specific performance requirements, resulting in more efficient and reliable vehicles.

One of the key advantages of CNC automotive parts lies in their stringent quality control measures. CNC machines can run automated inspections to verify each manufactured part's accuracy and consistency, ensuring that only components meeting strict quality standards are utilized in gear systems. This process minimizes the risk of faulty parts, enhances the overall reliability of gear systems, and ultimately improves vehicle safety.

As automotive manufacturers strive for excellence in gear system performance, RICHCONN emerges as a leader in the production of CNC automotive parts. With years of expertise and cutting-edge technology, RICHCONN specializes in manufacturing high-quality precision parts that meet the demanding requirements of the automotive industry. Their commitment to precision, customization, and superior quality control ensures that gear systems equipped with RICHCONN components operate flawlessly.

The precision of CNC automotive parts plays a vital role in the performance, durability, and efficiency of gear systems in automotive vehicles. With their near-perfect accuracy, customization capabilities, and stringent quality control measures, CNC automotive parts revolutionize the automotive industry by enabling seamless power transmission and enhanced performance. RICHCONN's position as a leading manufacturer exemplifies the importance of CNC technology in meeting the ever-increasing demands of the automotive industry. Embracing CNC automotive parts ensures the reliability and longevity of gear systems, providing a seamless driving experience for motorists worldwide.

The Benefits of Anodizing Precision Machined Aluminum ProductsOctober 19, 2023Why might you want to anodize aluminum? There are several good reasons to consider anodizing aluminum parts. Anodizing aluminum creates a layer of oxide and forms a layer on the surface of the aluminum.view

The Benefits of Anodizing Precision Machined Aluminum ProductsOctober 19, 2023Why might you want to anodize aluminum? There are several good reasons to consider anodizing aluminum parts. Anodizing aluminum creates a layer of oxide and forms a layer on the surface of the aluminum.view What Does Color Flaw Detection Mean?October 19, 2023Color flaw detection is a method of non-destructive testing, it is a surface inspection method, mainly used to detect such as the naked eye can not identify the cracks and other surface damage, such as the detection of stainless steel material near the surface defects (cracks), porosity, porosity, delamination, unwelded and unfused and other defects (also known as PT detection).view

What Does Color Flaw Detection Mean?October 19, 2023Color flaw detection is a method of non-destructive testing, it is a surface inspection method, mainly used to detect such as the naked eye can not identify the cracks and other surface damage, such as the detection of stainless steel material near the surface defects (cracks), porosity, porosity, delamination, unwelded and unfused and other defects (also known as PT detection).view Anodized Aluminum: How to Anodize Aluminum Parts?January 23, 2024Are you familiar with anodizing aluminum? If not, you can read this article and get to know about the process and other related things.view

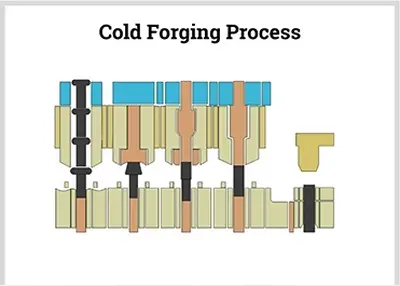

Anodized Aluminum: How to Anodize Aluminum Parts?January 23, 2024Are you familiar with anodizing aluminum? If not, you can read this article and get to know about the process and other related things.view When to Use the Cold Heading ProcessOctober 19, 2023As a professional machining manufacturer, we use the most appropriate machining process to precision machine products and reduce customers' purchasing costs and production time. Precision casting, forging, and profile machining are all very common. In addition cold heading, oil extrusion and other processes are also often used.view

When to Use the Cold Heading ProcessOctober 19, 2023As a professional machining manufacturer, we use the most appropriate machining process to precision machine products and reduce customers' purchasing costs and production time. Precision casting, forging, and profile machining are all very common. In addition cold heading, oil extrusion and other processes are also often used.view Electrophoresis Plating in Corrosion ResistanceJanuary 5, 2024When it comes to protecting metal objects from corrosion, electrophoresis plating is a game-changer. This process not only enhances the appearance of the metal but also provides a robust shield agains...view

Electrophoresis Plating in Corrosion ResistanceJanuary 5, 2024When it comes to protecting metal objects from corrosion, electrophoresis plating is a game-changer. This process not only enhances the appearance of the metal but also provides a robust shield agains...view CNC Steel: Key to Precision in CNC MachiningNovember 6, 2023Are you seeking the perfect material for your CNC machining project, one that promises precision and durability? Look no further than CNC steel. In this guide, I'll take you through the world of CNC steel, helping you understand its various types, selection criteria, and how to make the most of this essential material in your CNC machining endeavors.view

CNC Steel: Key to Precision in CNC MachiningNovember 6, 2023Are you seeking the perfect material for your CNC machining project, one that promises precision and durability? Look no further than CNC steel. In this guide, I'll take you through the world of CNC steel, helping you understand its various types, selection criteria, and how to make the most of this essential material in your CNC machining endeavors.view

EN

EN

ru

ru