Welding is a highly efficient method used to join metal pieces and create single components, commonly employed in sheet metal fabrication for finalizing part production. However, despite its advantages, there is a risk of welding defects that can lead to weld failure.

Sheet metal welding often exhibits defects caused by incorrect welding patterns or methods, compromising the strength of the joint and potentially causing product failure. It is important to know that some of the defects can be accepted as long as they do not violate established standards and quality requirements. However, defects such as cracks are not acceptable. This guide will assist you in identifying common defects in welds, understanding their causes, and providing remedies to address them.

Welding defects result from poor welds that weaken the joint and are defined as points that fall outside the acceptable tolerance range in the welding process.

Imperfections may occur in terms of dimensional deviations, where the outcome does not meet the required standards. They can also manifest as discontinuities or variations in material properties. Welding defects commonly stem from factors like incorrect welding patterns, improper material selection, lack of skill, or incorrect machine settings such as welding speed, current, and voltage.

Resolving welding defects involves various options depending on the situation. Sometimes, the metal can be repaired, while in other cases, the metal has melted and the welding process needs to be restarted.

Weld discontinuities can arise due to different reasons, resulting in various welding defects. These defects can be categorized into two main groups: internal welding defects and external welding defects.

Internal welding defects are characterized by their occurrence beneath the material's surface, making them visually undetectable. Despite being invisible, they are equally significant as external defects. Examples of internal defects include incomplete fusion, slag inclusion, and incomplete penetration.

Incomplete fusion occurs as a consequence of subpar welding practices, leading to insufficient melting of the parent and base metals. This causes gaps to form in the weld zone, resulting in a lack of fusion. This defect can manifest in different ways:

1. Lack of fusion between the parent metal and the weld metal at the root of the weld.

2. Lack of sidewall fusion between the parent metal and the weld metal at the sidewall of the weld.

3. Lack of inter-run fusion between adjacent layers of weld metal during multi-run welding.

Although this defect is primarily internal, incomplete fusion can also be observed on the outer surface of the weld. This occurs when there is improper fusion between the outer sidewall and the parent metal.

Causes:

Insufficient heat input leads to inadequate melting of the metals.

Incorrect joint angle, torch angle, and bead position.

Excessively large weld pool.

Remedies:

Using higher welding current and slower travel rates to ensure proper melting of the metals.

Improving welding positions, including joint angle, torch angle, and bead position.

Lowering the deposition rate.

Slag inclusion is a welding defect that occurs when slag becomes trapped in the weld bead, compromising the durability and structure of the metal. It can manifest either on the surface of the weld or between welding cycles. Slag inclusion is commonly observed in welding processes that involve the use of flux, such as stick, flux-cored, submerged arc welding, and brazing. The presence of slags, resulting from the melting of flux during welding, adversely affects the weldability and toughness of the metal, ultimately reducing the structural performance of the weld.

Causes:

Inadequate welding angle and travel speed of the welding torch.

Poor pre-cleaning of the weld surface edge.

Insufficient welding current density results in inadequate heat for the metals.

Remedies:

Using higher welding current density.

Maintaining optimal welding angle and travel speed to prevent slag inclusion in the weld pool.

Ensuring consistent cleaning of the weld edge and removal of slag from each layer.

Incomplete penetration typically happens in butt welding when there is an incomplete filling of the gap between the metals throughout the joint thickness. This results in one side of the joint not being fused at the root.

Cause:

Improper application of welding technique.

Incorrect electrode size.

Low deposition rate.

Remedies:

Utilizing the appropriate welding technique and following the correct procedure.

Increasing the deposition rate.

Selecting the proper electrode size.

External welding defects, also referred to as surface or visual welding faults and defects, are observable on the surface itself. They encompass surface cracks, overlaps, undercuts, porosity, and spatter. This section will provide a detailed discussion of each defect.

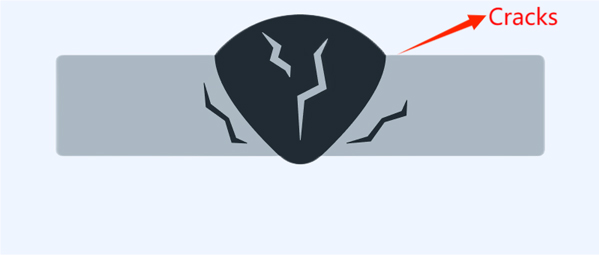

Cracks are considered the most severe welding discontinuities as they have the potential to expand rapidly and ultimately lead to failure. Weld cracks are categorized based on their formation within the weld bead.

Longitudinal cracks run parallel to the weld bead, while transverse cracks form across the width of the weld. Crater cracks occur at the end of the bead, where the arc concludes.

Welding cracks can occur at different temperatures:

Hot cracks

Hot cracks develop when weld joints solidify at temperatures exceeding 1000°C, leading to crystallization of the parent and base metals. The main causes of hot cracks are the use of incorrect filler metal and high heating and cooling rates in processes like laser welding.

Cold cracks

Cold cracks emerge after the cooling phase of the weld metal. These cracks may appear hours or even days after the completion of the metal's cooling process.

Causes:

Utilizing hydrogen shielding gas when welding ferrous metals.

Presence of a ductile base metal combined with the presence of residual stress.

Constrained expansion and contraction of the metal due to rigid joints.

High levels of sulfur and carbon.

Remedies:

Preheating the metals and implementing gradual cooling of the weld joints.

Ensuring acceptable weld joint gaps.

Selecting the appropriate welding materials.

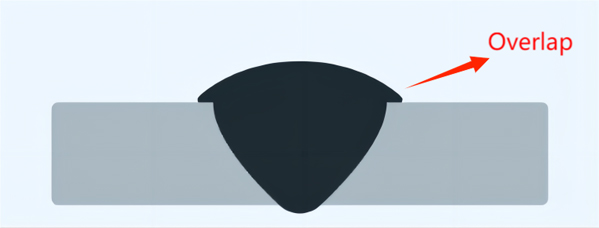

A weld overlap is a welding defect characterized by the filler material at the weld's toe not properly bonding with the metal. As a result, the weld pool excessively flows and extends past the toe. In this situation, the weld metal forms an angle below 90 degrees.

Causes:

Incorrect welding procedure.

Inappropriate selection of welding materials.

Improper preparation of base metals.

Remedies:

Utilizing smaller welding current.

Implementing proper welding techniques.

Using shorter welding electrodes.

Undercut defects are welding imperfections that manifest as irregular grooves resembling notches on the base metal. They arise from the melting of the base metal away from the weld zone and are distinguished by their length, depth, and sharpness. Undercut defects align parallel to the weldment and result in a reduction in thickness. This makes the weld joint more prone to fatigue. The types of undercuts include continuous undercut, inter-run undercut, and intermediate undercut.

1. Continuous Undercut

Continuous undercut is an undercut defect that extends along the entire length of the weld, resulting in a continuous groove on the base metal.

2. Inter-run Undercut

Inter-run undercut occurs between individual weld passes in multi-pass welding. It often happens when the subsequent pass is not properly fused to the previous pass, creating a groove at the juncture of the welds.

3. Intermediate Undercut

The intermediate undercut is a type of undercut defect that occurs partway along the length of the weld, creating a groove in the base metal. It typically happens due to inconsistent heat distribution or improper welding technique.

Causes:

Excessive arc voltage.

Incorrect electrode angle or using an electrode that is too large.

Incorrect selection of filler metal.

Inappropriate choice of shielding gas.

Remedies:

Utilizing a smaller arc length, reducing voltage, and adjusting travel speed.

Maintaining a 30 to 45-degree electrode angle.

Reducing the diameter of the electrode.

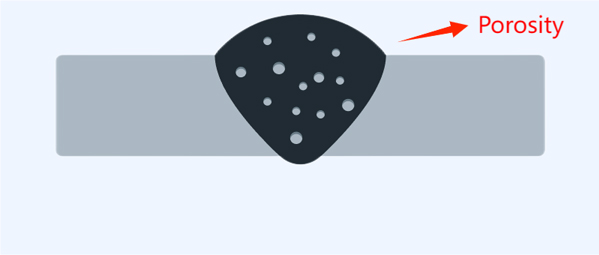

Porosity defects also referred to as wormhole welds, occur when air or gas bubbles become entrapped in the weld. During the welding process, gases like hydrogen, carbon dioxide, and steam are often generated. A cross-section of weld beads affected by porosity often exhibits a sponge-like appearance due to the accumulation of trapped air bubbles.

The entrapped gases can be localized or uniformly distributed within the weld. These gas bubbles can weaken the weld joint, making it vulnerable to fatigue and damage. These orbital welding errors can occur in different forms, including:

1. Gas Porosity

This type of error results in small, spherical-shaped cavities due to trapped gases. It can manifest as surface pores, elongated cavities, or linear porosity, among other variations.

2. Worm Holes

These errors appear as elongated or tubular cavities formed when trapped gases solidify. They can be observed as individual holes or a cluster of holes scattered across the weld surface.

3. Surface Porosity

This type of error breaks the surface of the weld metal, causing porosity to be visible on the weld's exterior.

Causes:

Insufficient or lack of shielding gas.

Mishandling or damage to shielding gas cylinder.

Welding current set too low or too high.

Excessive travel speed during welding.

Remedies:

Thoroughly clean the welding surface.

Establish the proper gas flow rate to ensure adequate shielding.

Regularly inspect and guard against moisture contamination in the shielding gas cylinder.

Adjust welding current and travel speed to optimal settings.

Spatter is a discontinuity welding that arises from the ejection of molten metal droplets onto the metal surface during the welding process. Once these droplets cool down, they solidify and adhere to the surface. While spatter typically does not affect the structural integrity of the weld, it often needs to be removed, leading to additional costs.

Causes:

Insufficient voltage and excessive amperage current settings.

Incorrect selection of shielding gas.

Use of an inflexible electrode working angle.

Utilizing a wet electrode and maintaining a larger arc length.

Contamination of the metal surface.

Remedies:

Ensure the correct polarity and adjust the welding current.

Use the appropriate shielding gas.

Increase the electrode angle and decrease the arc length.

Thoroughly clean the metal surface before welding.

Distortion occurs as a result of the excessive heat applied during the welding process, causing alterations in the position and dimensions of metal plates. Thinner plates are more susceptible to this defect since their smaller surface area restricts efficient heat dissipation.

Causes:

Uneven temperature gradients during welding.

Excessive weld passes with small diameter electrodes.

High residual stress in the metal plate to be welded.

Remedies:

Follow appropriate temperature gradients for welding.

Optimize the design for sheet metal parts considering weld pass requirements.

Control the amount of weld metal to reduce contraction forces.

Mechanical damages, which appear as indentations on the parent metals or welds, frequently occur due to accidents during the welding process. These problems can arise as a result of using improper welding techniques or incorrectly using welding tools.

Causes:

Mishandling of electrode holders.

Excessive force applied during chipping.

Inefficient use of grinders.

Failure to establish a proper arc-to-metal connection.

Remedies:

Handle electrode holders properly after welding.

Utilize welding tools with professionalism.

Use controlled and moderate hammering when necessary.

Ensure the arc is engaged before starting the welding process.

Welding is a complex process that requires careful selection of techniques and proper execution to avoid welding defects. These defects can have a detrimental impact on product quality and business performance. It is vital to have a thorough understanding of the various types of welding defects, their underlying causes, and effective prevention methods.

To achieve your manufacturing objectives, it is crucial to invest in appropriate tools and select a dependable metal welding partner. Richconn offers top-notch sheet metal welding services, supported by robust facilities and a stringent quality inspection process. The team of highly skilled engineers and technicians utilizes the right materials and techniques to produce parts that meet your specific requirements. Contact us today to get started on your project.

CNC Control Systems: Unraveling the Core of Computer Numerical ControlNovember 3, 2023Are you ready to delve into the heart of modern manufacturing technology? Welcome to the world of CNC Control Systems, where precision and automation meet to revolutionize industries.view

CNC Control Systems: Unraveling the Core of Computer Numerical ControlNovember 3, 2023Are you ready to delve into the heart of modern manufacturing technology? Welcome to the world of CNC Control Systems, where precision and automation meet to revolutionize industries.view Importance Of CNC Machining In Manufacturing Different PartsOctober 24, 2023CNC machining services help you to manufacture and fabricate different parts of metal as per the requirements. This process also helps in creating tolerances for various materials and metal parts. This process is usually a subtractive method of producing metal parts.view

Importance Of CNC Machining In Manufacturing Different PartsOctober 24, 2023CNC machining services help you to manufacture and fabricate different parts of metal as per the requirements. This process also helps in creating tolerances for various materials and metal parts. This process is usually a subtractive method of producing metal parts.view Rivets: 25 Types Of Introduction And User GuideSeptember 26, 2023Rivets are parts that join multiple components and structures together to form a complete body. These parts can be manipulated with some specialized tools. One of the panaceas of manufacturing is rivets. Depending on their design requirements and performance, different types of rivets can be used.view

Rivets: 25 Types Of Introduction And User GuideSeptember 26, 2023Rivets are parts that join multiple components and structures together to form a complete body. These parts can be manipulated with some specialized tools. One of the panaceas of manufacturing is rivets. Depending on their design requirements and performance, different types of rivets can be used.view Bead Blasting 101: How Does a Bead Blaster Work?November 2, 2023Bead blasting is an abrasive technique where media is projected onto a surface. How does a bead blaster work to ensure a smooth bead blasting process? Read on.view

Bead Blasting 101: How Does a Bead Blaster Work?November 2, 2023Bead blasting is an abrasive technique where media is projected onto a surface. How does a bead blaster work to ensure a smooth bead blasting process? Read on.view The Features and Characteristics of CNC Milling MaterialsFebruary 29, 2024CNC milling, a cornerstone in the manufacturing processes of various industries, hinges significantly on the selection of materials.view

The Features and Characteristics of CNC Milling MaterialsFebruary 29, 2024CNC milling, a cornerstone in the manufacturing processes of various industries, hinges significantly on the selection of materials.view What Are Machining Operations?November 3, 2023Machining operations are at the core of modern manufacturing. These processes are the backbone of industries like aerospace, automotive, and electronics, allowing for precise shaping and finishing of materials.view

What Are Machining Operations?November 3, 2023Machining operations are at the core of modern manufacturing. These processes are the backbone of industries like aerospace, automotive, and electronics, allowing for precise shaping and finishing of materials.view