Richconn has developed extensive experience in cold chamber die casting, assembly and metal fabrication. We are proudly certified to the rigors of TS 16949 and ISO 9001:2008, providing our customers with the assurance of high quality manufacturing.

Strict quality control process.

Good supply chain management for timely delivery.

Global market coverage in 70+ countries.

Provide customized cold chamber die casting solutions.

Sixteen years of strong commitment and continued growth have made Richconn a leading company you can trust. Our stainless steel cold chamber die casting process imparts superior corrosion resistance and outstanding durability to the finished product. However, what's even more exciting is that we don't just provide exceptional products, we also offer intelligent advice, recommending the best methods and materials to ensure the best possible outcome for your project.

Main applications include automotive parts, electronic housings and aerospace components.

Mainly used in the automotive and aerospace industries.

Mainly used in hardware accessories, electrical components and decorations.

Mainly used in power transmission components and communication equipment.

Mainly used in marine environment or food processing equipment.

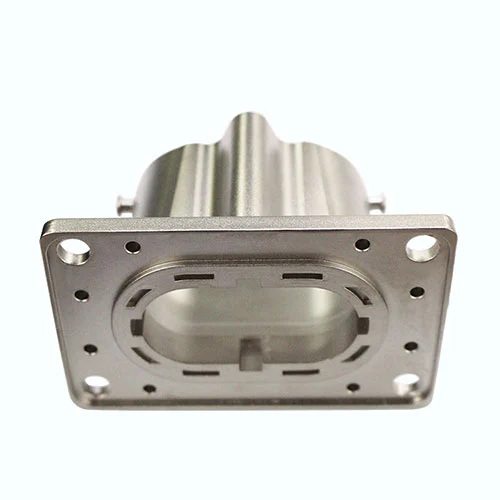

Richconn offers OEM cold chamber die casting services to produce your customized parts.

· Richconn has introduced advanced equipments and has 16 years of manufacturing experience, mainly dealing with modular product development and design, CNC machining design and manufacturing, hardware stamping, zinc and aluminum alloy die-casting, slide rails.

· Our equipments include 23 sets of 80300T double-axis Taiwan imported punching machines, 7 sets of 125T900T zinc-aluminum die-casting machines, 36 sets of CNC, 8 sets of automated robotic sanding equipments and automated spraying equipments.

· We pursue the ultimate of our products with exquisite craftsmanship and have a superb technical team that can provide customers with product design, research and development, and drawing improvement in order to reduce costs and increase market sales.

· We provide perfect after-sales service with experienced sales team and strong technical support to solve customers' worries and protect investment interests.

Cold chamber die casting is a metal die casting process used to manufacture parts made from high melting point metal alloys. The process creates high-quality, high-precision parts by placing molten metal in solid form into a cold chamber furnace and then injecting it into a mold through an injection system. This method is suitable for high melting point metals, reduces porosity and impurities, and provides superior surface quality, and is widely used in the automotive, electronics, and aerospace industries.

The cold chamber die casting process involves placing a metal alloy in solid form into a device known as a cold chamber furnace and then pushing the molten metal through an injection system by pushing the molten metal under pressure into a specially designed mold. Once the molten metal has been injected into the mold, the metal cools and solidifies inside the mold to form the desired shape of the part. Once the part is formed, it needs to be cooled within the mold to ensure that the part cools evenly and maintains its structural integrity, once the part is completely cooled and has the desired shape, the mold opens and the part can then be removed. At this stage, any burrs or bad edges may need to be removed to ensure that the final part has the required surface quality and accuracy.

Suitable for high melting point metals: Cold chamber die casting is suitable for high melting point metal alloys such as aluminum, copper and magnesium, which are difficult to handle in conventional hot chamber die casting.

High precision and surface quality: This process produces high precision parts with excellent surface quality, reducing the need for subsequent machining.

Reduced porosity and impurities: Because the metal cools and solidifies at lower temperatures, cold chamber die casting helps to minimize the formation of porosity and impurities, improving the quality of the part.

Complex geometries: It allows the manufacture of parts with complex geometries without the need for additional processes or assembly.

High throughput: Cold chamber die casting machines typically have high throughput and can produce large quantities of parts in a short period of time.

Repeatability: Process parameters can be precisely controlled, resulting in highly repeatable parts.

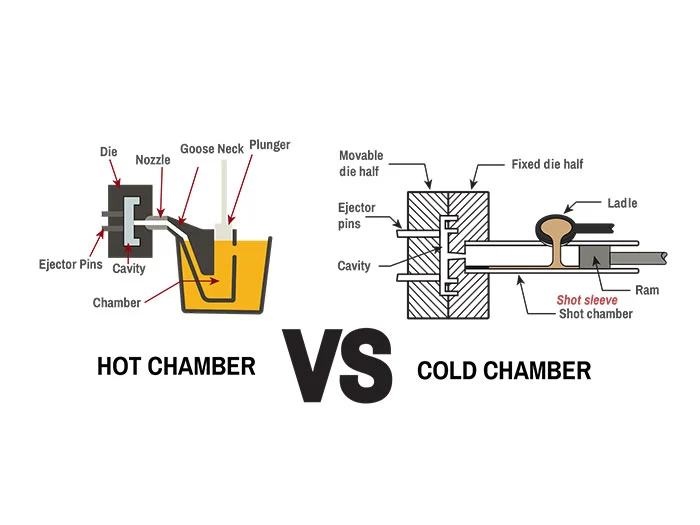

Cold chamber die casting and hot chamber die casting are two different die casting process, they in the principle of operation, applicable materials and application areas there are significant differences.

Cold chamber die casting for high melting point metal alloys, provide high precision and excellent surface quality, suitable for the requirements of high quality and complex geometric shape of the parts manufacturing, such as automotive and electronic.

Hot chamber die casting is used for low melting point metals and is typically used for high volume production, but has lower precision and surface quality than cold chamber die casting and is suitable for relatively less demanding applications.

EN

EN

ru

ru