From now on, you have the flexibility to choose your CNC delivery times and thus determine your own delivery dates and costs for your CNC parts. As part of the Flexible Manufacturing option, our lead times of 6 to 12 days offer you a lower price - and you'll still receive your parts faster than most other suppliers.

Of course, you can still choose standard delivery with as little as 3 days notice, or, for urgent projects, our Rapid Manufacturing service if you need parts within a day. Simply choose the best delivery time for your project.

Of course, even with more cost-effective manufacturing options, you can benefit from the same automated CNC machining services (including feasibility analysis), the same choice of materials, and the same quality of parts as our free quote service. The only difference is the delivery time.

Our free consultation service platform gives you complete control over your CNC machining project. Please proceed as follows:

Upload your CAD file to the quotation system

Enter the required material and part quantities

Display the different delivery times and the corresponding costs

Select the desired delivery date

You will then receive a free quote from us, including a feasibility analysis of your 3D design.

If your design is feasible, just place the order and we will do the rest!

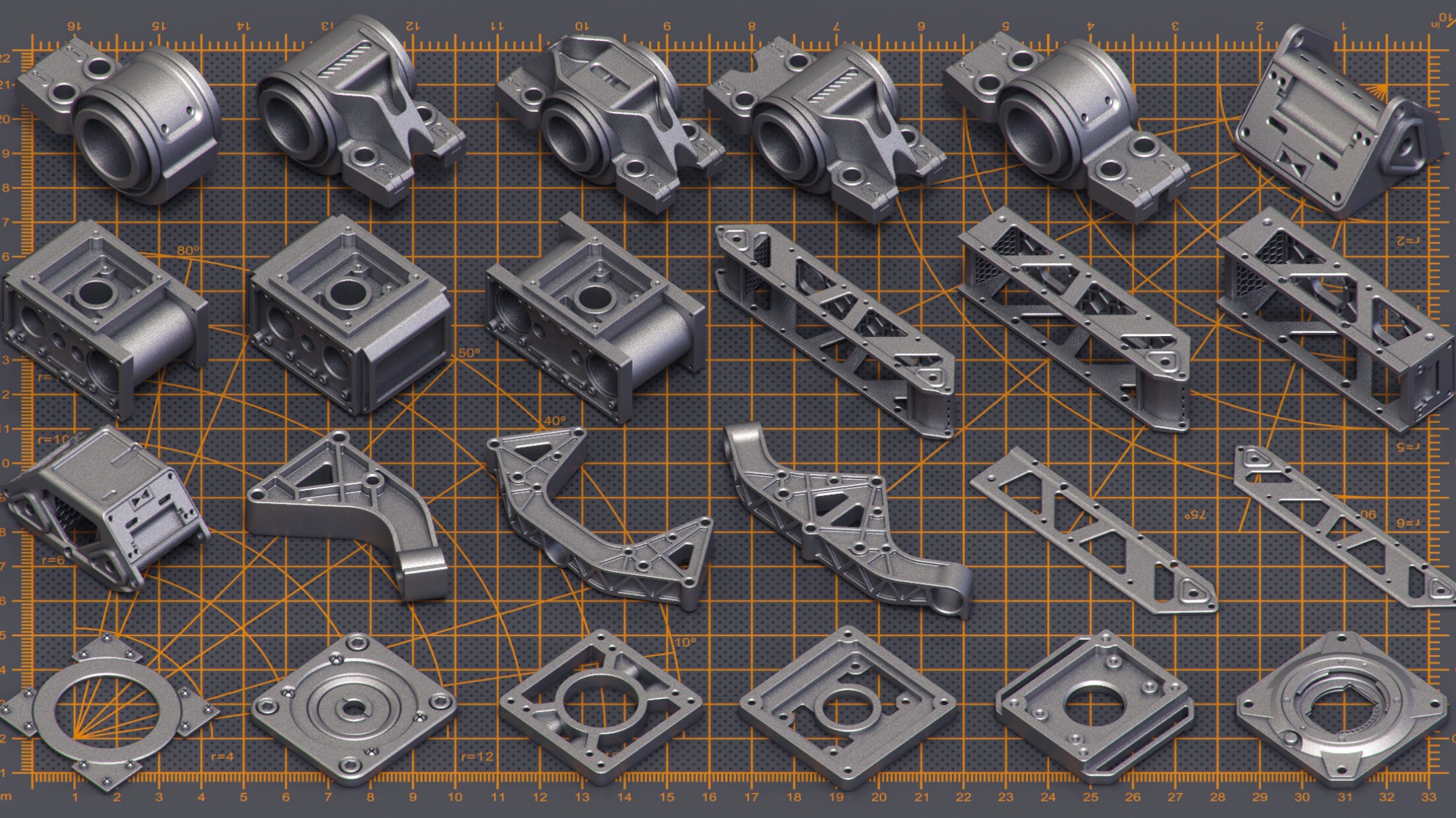

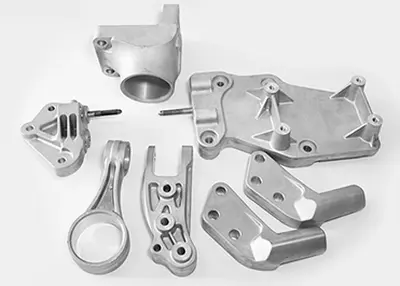

We use 3 Axis machining and 5 Axis CNC machining for rapid prototyping, producing small batches of end-use plastic and metal parts. We also use power tooling (a combination of turning and milling capabilities) to produce cylindrical parts from metal rods.

Using our new e-commerce platform, you can easily add threads to your interactive products, such as in the form of self-locking and helical threaded inserts. Our automated design analysis allows you to adjust difficult-to-machine features before you put the part into production, eliminating costly rework later in product development.

We stock more than 30 technical plastics and metals for a variety of applications and industries. These include plastics such as ABS, polycarbonate, nylon and PEEK, and metals such as aluminum, stainless steel, magnesium and copper.

See for yourself today and upload a CAD file for a free quote, including a feasibility analysis.

Fasteners 101: Common Types of Automotive FastenersAugust 24, 2023Automotive fasteners are an essential component in the construction and maintenance of vehicles. As a result, automotive part manufacturing relies on high-tolerance designs that include connecting mec...view

Fasteners 101: Common Types of Automotive FastenersAugust 24, 2023Automotive fasteners are an essential component in the construction and maintenance of vehicles. As a result, automotive part manufacturing relies on high-tolerance designs that include connecting mec...view Unveiling the World of Complex Machined Parts: A Comprehensive ExplorationNovember 14, 2023Embark on a journey into the intricate realm of complex machined parts, where precision meets innovation and engineering excellence takes center stage. In this comprehensive exploration, we'll delve into the definition, manufacturing processes, applications across industries, quality standards, material selection, market trends, and even the key players in the supply chain. Get ready to unlock the secrets behind these components that power the machinery shaping our modern world.view

Unveiling the World of Complex Machined Parts: A Comprehensive ExplorationNovember 14, 2023Embark on a journey into the intricate realm of complex machined parts, where precision meets innovation and engineering excellence takes center stage. In this comprehensive exploration, we'll delve into the definition, manufacturing processes, applications across industries, quality standards, material selection, market trends, and even the key players in the supply chain. Get ready to unlock the secrets behind these components that power the machinery shaping our modern world.view What Is High Carbon Steel? What Is the Difference Between High Carbon Steel Sk2, Sk4, Sk5, Sk7, Etc.?October 27, 2023High carbon steel is a type of steel with a carbon content between 0.6% and 1.7%, which contains much more carbon than ordinary carbon steel, and is therefore also caled carbon tool steel. High carbon steel has high hardness, high strength, low toughness, and is easy to quench and temper, so it is widely used in the manufacture of machine parts, tools and blades that require high strength and hardness.view

What Is High Carbon Steel? What Is the Difference Between High Carbon Steel Sk2, Sk4, Sk5, Sk7, Etc.?October 27, 2023High carbon steel is a type of steel with a carbon content between 0.6% and 1.7%, which contains much more carbon than ordinary carbon steel, and is therefore also caled carbon tool steel. High carbon steel has high hardness, high strength, low toughness, and is easy to quench and temper, so it is widely used in the manufacture of machine parts, tools and blades that require high strength and hardness.view What Are the Benefits of Cnc Precision Machining?October 25, 2023The sunk costs of CNC precise machining may be a bit higher than traditional machining methods. However, in the long run, the benefits offered by the process definitely make it worth the extra investment, and today Richconn will share with you what all the benefits of CNC machining are.view

What Are the Benefits of Cnc Precision Machining?October 25, 2023The sunk costs of CNC precise machining may be a bit higher than traditional machining methods. However, in the long run, the benefits offered by the process definitely make it worth the extra investment, and today Richconn will share with you what all the benefits of CNC machining are.view Richconn: Secondary ServicesOctober 12, 2023Many of our customers order parts that come ready-made from plastic injection molding or CNC machining. Many others, however, want or need "secondary machining" of the parts so produced.view

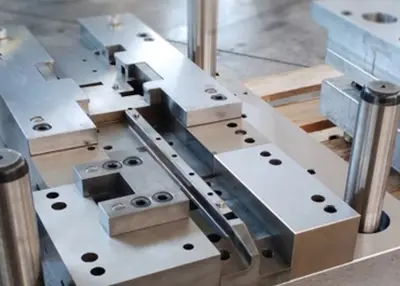

Richconn: Secondary ServicesOctober 12, 2023Many of our customers order parts that come ready-made from plastic injection molding or CNC machining. Many others, however, want or need "secondary machining" of the parts so produced.view Experience Sharing on Design and Manufacturing of Metal Stamping DiesJuly 21, 2023Here, we will share some specific design and manufacturing experiences to provide our understanding of dies accumulated over the years. Through this article, we hope to give you a better understanding...view

Experience Sharing on Design and Manufacturing of Metal Stamping DiesJuly 21, 2023Here, we will share some specific design and manufacturing experiences to provide our understanding of dies accumulated over the years. Through this article, we hope to give you a better understanding...view

EN

EN

ru

ru