With the ever-increasing requirements for product quality, especially in some high-precision and high-demand industrial fields, such as automobile manufacturing, aerospace, medical devices, etc., the appearance and dimensional accuracy of a product become a key factor in determining its performance and market competitiveness. However, the traditional CNC machining technology, although able to meet the basic machining needs to a certain extent, often seems to be unable to deal with the surface finish and dimensional accuracy. Especially in some occasions with extremely high requirements for surface quality, such as high-precision bearings, high-precision gears, high-precision molds, etc., CNC machining is difficult to meet its requirements.

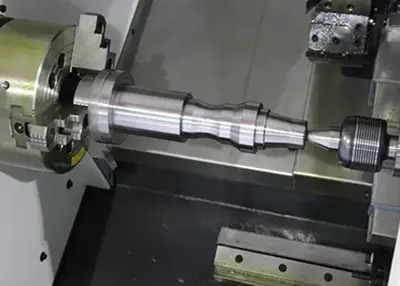

However, CNC honing technology came into being and became a sharp tool to solve this problem. CNC honing technology is a combination of CNC technology and honing technology based on the computer to accurately control the honing tool's trajectory and parameters for high-precision machining of the surface of the workpiece. It can not only significantly improve the surface finish and dimensional accuracy of the product, but also ensure the stability and reliability of the machining process, improve production efficiency and reduce production costs. Today we will take you to understand the CNC honing service.

CNC honing service, as a cutting-edge precision machining technology, its definition is not only limited to simple mechanical operation, but also combines modern CNC technology and traditional honing technology to achieve high precision and high-efficiency machining processing on the surface of the workpiece. Its core lies in the precise control of the honing tool's movement trajectory, speed, pressure and other key parameters through the high-precision CNC system, so as to ensure the stability and accuracy of the machining process.

In terms of characteristics, CNC honing service is firstly reflected in its high efficiency. Traditional honing technology often relies on the experience and skills of the operator, while CNC honing automatically completes the entire machining process through the preset CNC program, which greatly reduces the influence of human factors and improves machining efficiency. At the same time, due to the precise control of the CNC system, the error in the machining process is greatly reduced, thus ensuring the stability of machining accuracy and product quality.

Secondly, the precision of CNC honing service is also one of its important features. Through the precise control of the CNC system on the movement trajectory of the honing tool, it can achieve the processing of tiny details on the surface of the workpiece, which makes the processed products with high surface finish and high dimensional accuracy and meets the demand for high-precision products in modern industry.

In addition, CNC honing service also has a high degree of flexibility and expandability. Due to the editable nature of the CNC program, the processing parameters and process flow can be adjusted according to different processing needs to achieve the processing of workpieces of different shapes, sizes and materials. At the same time, CNC honing equipment can also be integrated with other automation equipment to form a complete automated production line, further improving production efficiency and quality.

With great flexibility and scalability, CNC honing service has a wide range of application prospects and huge market potential in industrial production. Take the engine block as an example, after machining is completed, it is often necessary to carry out honing on the piston hole to eliminate burrs and small defects produced during machining, to ensure the smoothness and stability of the engine during high-speed operation. CNC honing service is one of the effective means to meet this demand, and its high-precision and high-efficiency machining characteristics have significantly improved the machining quality of the engine block.

CNC honing service as an important technological innovation in the field of modern industrial manufacturing, its service scope is wide and diverse application areas. From automobile manufacturing to aerospace, from precision machinery to medical equipment, CNC honing technology plays an indispensable role. Take automobile manufacturing as an example, CNC honing technology is widely used in engine block, crankshaft and other key components of precision machining, effectively improving the surface quality and performance stability of parts. According to statistics, using CNC honing technology processing of automotive engine block, its surface roughness can be reduced to Ra0.2μm (see note ①) below, greatly improving the engine's fuel efficiency and power performance.

Note ①: Ra refers to the roughness, Roughness Average abbreviation. The unit is usually a micron (μm), which refers to the processing of the surface has a small pitch and small peaks and valleys of unevenness. The smaller the latter value, the smoother the surface, Ra0.2 is generally used to indicate the mirror effect.

In addition, in the aerospace field, CNC honing technology also plays an important role. Due to the extremely high requirements for precision and surface quality of aerospace parts, traditional honing technology is difficult to meet its needs. And CNC honing technology through accurate CNC programming and automated operation can achieve high precision machining of parts and surface quality of significant improvement. For example, after processing with CNC honing technology, the surface roughness of the turbine blades of certain aircraft engines will be reduced by more than 50%, effectively improving the thrust-to-weight ratio and reliability of the engine.

CNC honing technology is also widely used in precision machinery, medical equipment and other fields. In the field of precision machinery, CNC honing technology is used in the processing of high-precision bearings, gears and other parts, improving the transmission efficiency and stability of mechanical equipment. In the field of medical equipment, CNC honing technology is used to manufacture high-precision artificial joints, dental implants and other medical devices, making a positive contribution to people's health.

In summary, CNC honing service with its wide range of applications and significant technical advantages, the whole has become one of the indispensable and important technologies in the field of modern industrial manufacturing. With the continuous progress of science and technology and the continuous upgrading of industrial manufacturing, CNC honing technology will continue to play a greater role in the development of industrial manufacturing areas to inject new momentum.

The core principle of CNC honing technology lies in the combination of its advanced computer control system and precise mechanical structure, which achieves high-precision processing of the workpiece surface by precisely controlling the movement trajectory and parameters of the honing tool. This technology combines the essence of modern CNC technology and the traditional honing process, which brings a revolutionary change to industrial production.

In the CNC honing equipment, high-precision CNC system is its ‘brain’, responsible for according to the preset procedures, precise control of the honing head rotation, feed speed, processing depth and other key parameters. At the same time, advanced sensors and feedback systems act as ‘eyes’ and ‘ears’, they can real-time monitoring of a variety of data in the machining process, such as machining temperature, cutting force, vibration, etc., to ensure machining accuracy and stability.

In terms of workflow, CNC honing service starts from workpiece preparation, which includes workpiece cleaning, positioning and fixing steps to ensure that the workpiece maintains a stable posture during the machining process. Subsequently, appropriate honing tools and machining parameters are selected according to the material, shape and machining requirements of the workpiece. The setting of these parameters is crucial, and they will directly affect the machining accuracy and efficiency.

During the machining process, the CNC system controls the motion of the honing head according to the preset program. The honing head rotates at high speed while carrying out feed movement along the preset trajectory to carry out precision machining on the surface of the workpiece. The sensor monitors the processing status in real time, and once an abnormality is found, it immediately feeds back to the CNC system, which will automatically adjust the processing parameters or take other measures to ensure the stability and precision of the processing.

CNC honing service usually includes two stages: rough honing and fine honing. Rough honing is used to remove most of the residue on the surface of the workpiece, laying the foundation for subsequent fine honing. Fine honing is used to finely machine the surface of the workpiece to achieve the required machining accuracy and surface quality. These two stages can be flexibly adjusted and optimized according to specific needs.

After machining, the workpiece needs to undergo quality inspection and subsequent processing. Quality inspection includes dimensional measurements, surface roughness testing, etc. to ensure that the machining quality meets the customer's requirements. Subsequent processing may include cleaning, rust prevention, packaging and other steps in order to deliver the workpiece to the customer.

CNC honing enables high-precision machining, with machining accuracies typically up to the micron level (μm) or even higher, which greatly improves product quality and performance.

CNC honing has the characteristics of high efficiency, through the optimization of machining parameters and the reduction of manual intervention, it can significantly improve machining efficiency and reduce production costs.

CNC honing also has a wide range of applicability, can be applied to a variety of materials and shapes of workpiece processing, to meet the needs of different customers. These advantages make CNC honing technology widely used in modern industrial production.

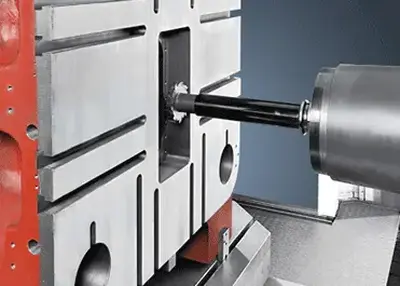

As an important tool in the field of modern industrial manufacturing, CNC honing equipment has a variety of types and specifications to meet different processing needs. In terms of equipment type, CNC honing machine is mainly divided into vertical, horizontal and gantry types. A vertical honing machine is suitable for processing high-precision, small-size workpieces, such as automotive parts, precision abrasives, etc.; A horizontal honing machine is more suitable for processing large, heavy workpieces, such as machine tool beds, large bearings, etc.. Gantry honing machine is widely used in the field of large workpiece processing with its high rigidity and large stroke.

In terms of specifications, CNC honing equipment is usually customized according to the size of the workpiece to be processed, the accuracy requirements and production efficiency and other factors. For example, the engine block production line of an automobile manufacturer adopts multiple high-precision vertical CNC honing machines, with a maximum machining diameter of up to 1,000mm, and machining accuracy controlled within 0.01mm, which effectively improves the machining quality and production efficiency of the engine block. In addition, some high-end CNC honing equipment also has an advanced CNC system and automation device, realizing the intelligence and automation of the machining process, and further improving the production efficiency and machining accuracy.

In practical application, the selection of CNC honing equipment should be based on specific processing needs. For example, for high-precision, small batch production of workpieces, you can choose high-precision, high-flexibility vertical CNC honing machine; and for high-volume, high-efficiency production needs, you can choose a high degree of automation, high productivity horizontal or gantry CNC honing machine. At the same time, when choosing equipment, should also consider the stability, reliability and after-sales service and other factors to ensure the long-term stable operation and efficient processing of the equipment.

CNC honing service process is a systematic and refined process, aiming at providing customers with efficient and precise honing solutions. In the overview of the service process, we make clear the various links from customer demand analysis to final delivery and acceptance.

Firstly, through in-depth communication with customers, we comprehensively understand their processing needs, workpiece materials, precision requirements and other key information, laying an adhering foundation for subsequent work.

Secondly, according to the customer's needs, we designate a detailed honing process plan, including equipment selection, parameter setting, machining path planning, etc., to ensure the scientificity and feasibility of the plan.

Next, we organize a professional technical team to carry out the actual operation, through the CNC honing equipment for high-precision processing of workpieces, and at the same time, we strictly control the parameters in the processing process to ensure the processing quality and efficiency.

Finally, we carry out quality inspection on the finished workpiece to ensure that it meets the customer's requirements and then deliver it for acceptance. In the whole service process, we focus on communication and collaboration with customers, timely feedback accuracy and problems, to ensure the transparency and controllability of the service process.

In addition, we also focus on the continuous optimization and innovation of the service process. Through the continuous introduction of new technologies and equipment, and the enhancement of the professionalism and operation ability of our technical team, we continuously improve the level and quality of our CNC honing service. At the same time, we actively maintain communication with our customers to understand the market demand and industry trends, so as to adjust the service strategy and direction in time to provide our customers with better quality services.

The little things count when it comes to your products' precise machining and surface treatment. Ensuring the quality and performance of your product requires you to define the needs of the refined part and develop the appropriate criteria for it.

First, it is critical to develop precise parameters based on your product needs. These parameters may include part-specific dimensions, tolerance ranges, material hardness, finish, and more. For example, if your product is a high-precision mechanical part, the finish of certain contact surfaces or sliding parts will need to meet specific standards to reduce friction and wear. When setting these parameters, you need to consider factors such as the product's usage scenario, performance requirements, and cost-effectiveness.

Secondly, it is also important to identify the areas that need to be honed. Honing is a precision machining method that removes trace cutting allowance from the surface of a workpiece by rotating and reciprocating motion, which improves the surface finish and accuracy of the workpiece. You need to determine which parts need to be honed according to the usage and performance requirements of the product. For example, honing is essential for parts that require a high-precision fit, parts that are subject to heavy loads, or parts that require high sealing.

Of course, if you don't know much about honing or don't have enough technical strength, then you can consider leaving this job to a professional company. In China, you can directly contact Richconn for the corresponding services.

Luckily, here comes Richconn!

Richconn has advanced honing equipment and a professional technical team that can make suitable machining program according to your needs and ensure the quality and delivery time. They can also provide technical support and after-sales service to ensure that your products always maintain good performance in the process of use.

1. Richconn can help you design your product prototype, you only need to put forward your needs, and they can do a fine plan for you.

2. Richconn can help you process any machining parts you need, including lathes, milling machines, grinding machines and other machining parts, they can be competent.

3. Richconn can do the corresponding honing treatment according to your needs so that you are not worried from design to processing.

4. Richconn can also do the corresponding post-treatment operation according to your requirements, including electroplating, oxidation, blackening and other surface treatments.

5. Richconn in the product completion, delivery will also be accompanied by relevant material reports, size inspection reports and other relevant reports. Ensure that your products do not have quality problems.

Come to contact Richconn. With only an email, you can get the best relevant services!

With the rapid development of modern industrial technology, the requirements for product finish and precision have reached an unprecedented level. This trend not only promotes the overall progress of the manufacturing industry, but also greatly promotes the wide application of CNC honing technology and market demand. We can foresee that in the future, the market demand for CNC honing will continue to expand, and become an important force to promote high-quality development in the field of industrial manufacturing.

Therefore, we have reason to believe that in the near future, CNC honing will enter the vision of more people. Whether it is professional manufacturing practitioners, or ordinary consumers, there will be more understanding and recognition of the value and advantages of CNC honing technology. At the same time, with the continuous expansion of the market and growing demand, there will be more high-quality CNC honing service providers. These suppliers will provide professional technical support and services to help enterprises better apply CNC honing technology and improve product quality and performance.

What is a CNC Lathe? Definitions, Uses, Types & BenefitsMarch 29, 2024This article provides a comprehensive introduction to CNC lathes, including their types, applications, benefits, and more. Read on and get detailed information.view

What is a CNC Lathe? Definitions, Uses, Types & BenefitsMarch 29, 2024This article provides a comprehensive introduction to CNC lathes, including their types, applications, benefits, and more. Read on and get detailed information.view How to remove chrome plating from sheet metal?November 24, 2023Chrome plating is a common metal finish that improves the wear resistance, corrosion resistance, aesthetics and hardness of the metal.view

How to remove chrome plating from sheet metal?November 24, 2023Chrome plating is a common metal finish that improves the wear resistance, corrosion resistance, aesthetics and hardness of the metal.view The Application of CNC Machining in Mechanical Equipment - SheetMay 7, 2024Let’s explore the world of sheet in mechanical equipment! Read this article to discover its importance, applications, manufacturing processes, and more.view

The Application of CNC Machining in Mechanical Equipment - SheetMay 7, 2024Let’s explore the world of sheet in mechanical equipment! Read this article to discover its importance, applications, manufacturing processes, and more.view CNC Router Machinery: Unveiling the Core of Modern ManufacturingNovember 2, 2023Are you ready to explore the cutting-edge world of CNC router machinery? Whether you are a seasoned professional in the field or someone just getting started, this comprehensive guide will equip you with the knowledge you need to harness the full potential of CNC router machinery. From understanding the fundamentals to exploring innovative services, let's dive in and take your CNC router experience to the next level.view

CNC Router Machinery: Unveiling the Core of Modern ManufacturingNovember 2, 2023Are you ready to explore the cutting-edge world of CNC router machinery? Whether you are a seasoned professional in the field or someone just getting started, this comprehensive guide will equip you with the knowledge you need to harness the full potential of CNC router machinery. From understanding the fundamentals to exploring innovative services, let's dive in and take your CNC router experience to the next level.view Navigating the World of Horizontal Boring TechnologyNovember 23, 2023Horizontal boring technology encompasses a realm of precision and innovation within precision CNC machining. At its core, it involves the utilization of specialized machinery, notably horizontal boring machines and mills, to create intricate cavities, bores, and holes with utmost accuracy.view

Navigating the World of Horizontal Boring TechnologyNovember 23, 2023Horizontal boring technology encompasses a realm of precision and innovation within precision CNC machining. At its core, it involves the utilization of specialized machinery, notably horizontal boring machines and mills, to create intricate cavities, bores, and holes with utmost accuracy.view Alodine: A Versatile and Effective Coating for AluminumDecember 5, 2023Alodine is a trade name for a chromate conversion coating that protects aluminum and other metals from corrosion. A chromate conversion coating is a thin layer of chromium compounds that forms on the surface of a metal when it reacts with a chromate solution.view

Alodine: A Versatile and Effective Coating for AluminumDecember 5, 2023Alodine is a trade name for a chromate conversion coating that protects aluminum and other metals from corrosion. A chromate conversion coating is a thin layer of chromium compounds that forms on the surface of a metal when it reacts with a chromate solution.view