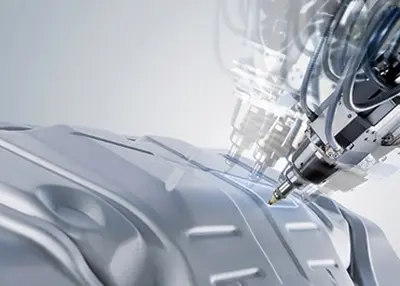

As is widely known, in a single piece of equipment, there are numerous locations that require the application of CNC machining. In fact, there are so many of these elements that it is impossible to cover them all in one go. Today, we will take everyone on a journey to gain a comprehensive understanding of the application fields and development trends of sheet in the equipment industry.

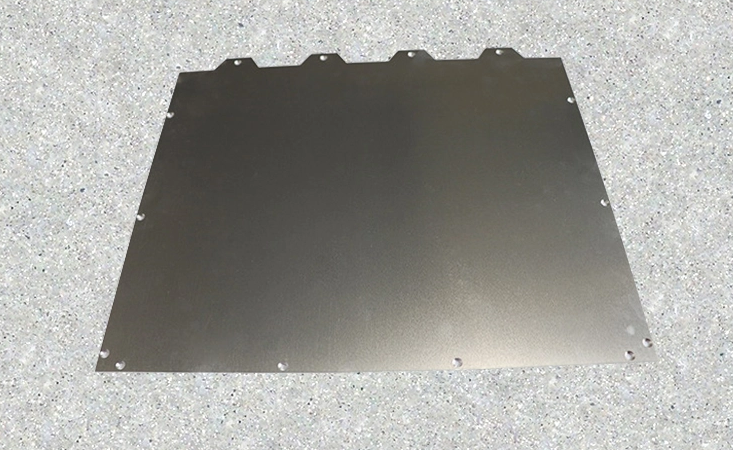

Sheet, which serves as a crucial component in mechanical equipment, is responsible for the large sheet-like structural parts in the equipment that are used for providing support, connecting, or transmitting power. Based on the material, purpose, and structural characteristics, sheet can be classified into various types, such as metal sheeting (e.g., aluminum sheet and steel sheet), non-metal sheet (e.g., plastic sheeting and wood sheeting), and composite material sheet.

Metal sheets, like aluminum sheet metal and steel sheets, have high strength, excellent thermal conductivity, and good plasticity, and they play a dominant role in heavy machinery and automatic production lines. Non-metal sheets, on the other hand, such as plastic sheets and wood sheets, are widely employed in precision machinery and electronic equipment due to their lightweight, insulation properties, and corrosion resistance. Furthermore, composite material sheets combine the advantages of multiple materials, offering higher performance and a wider range of application prospects.

Sheet metal serves as a vital component in machinery. Within heavy machinery, sheet metal plate is frequently employed to withstand immense pressure and impact forces, thereby guaranteeing the stability and dependability of the machinery. In precision machinery, sheet metal demands a high degree of precision and stability to ensure the accuracy and quality of mechanical processing. Additionally, in automated production lines, sheet metal processing, functioning as a crucial element, can facilitate efficient and precise material transmission and processing operations. Consequently, the quality and performance of sheet metal fabrication process have a direct impact on the overall performance and operational efficiency of the mechanical equipment.

Due to the relatively large size of sheet, generally more than 1 meter, it is also determined that it cannot be processed using conventional CNC equipment.

2.1 Firstly, the material factory will use heavy CNC sheet metal cutting equipment such as gantry cutting machines, flame cutting machines, and waterjet cutting machines to initially cut the material according to the required size for processing.

2.2 Then it will be sent to the machining workshop for processing. In the machining workshop, the workers will conduct an initial surface pretreatment on the sheet to make the shape of the material relatively regular. After the pretreatment is completed, it will generally be placed for a period of time, which is the so-called "aging treatment" to remove the stress of the material, so that we will not encounter material rebound or deformation due to stress during the subsequent fine machining. This time depends on the size and thickness of the sheet. Generally, the larger the size and the thinner the thickness, the longer the aging time required.

2.3 After several days of aging treatment, it will be sent to the machining workshop again for rough machining. The equipment for rough machining is mainly gantry milling machines. Due to the heavy weight of the sheet, in the gantry milling machine, its running speed will not be very fast, one is to ensure accuracy, and the other is to ensure safety. After the gantry milling is completed, the workshop will conduct a rough grinding on the sheet to grind out the flatness and finish of the sheet. After one grinding is completed, the sheet will be sent to the designated position again for secondary aging treatment.

2.4 After the secondary aging treatment is completed, the sheet will be pulled to the workshop again for fine machining. Fine machining is to adjust the slight changes caused by the aging treatment. All the hole positions will be processed, and after processing, it will be sent to the gantry grinder for fine grinding to grind out the flatness and finish required by the drawing. At this time, the sheet has already been formed. However, in order to ensure that it will not appear phenomena such as oxidation and corrosion during use, it is also necessary to conduct surface treatment on the sheet. Generally, the surface treatment of the sheet includes chromium plating, phosphating, blackening, oxidation, etc. After the surface treatment is completed, it is necessary to protect and pack the sheet. In this way, a complete sheet is processed.

The application of sheet in mechanical equipment is extensive and important, such as heavy machinery, precision machinery, and automatic production lines. In precision machinery, sheet is mainly used to support, connect and transmit power. It needs to have beneficial rigidity and anti-deformation ability to ensure that the machinery can remain stable when operating at high speed or under heavy load. In automatic production lines, the application of sheet plays a crucial role. Automatic production lines require equipment to have a high degree of stability, accuracy and efficiency, and as a key component, the quality and performance of sheet directly affect the overall operation effect of the production line. Therefore, the manufacturers of sheet need to continuously innovate and develop to improve the quality and performance of sheet to meet the changing and demanding market.

With the continuous progress of science and technology, as the core component in machinery, the materials and technologies of sheet are also constantly innovating. The emergence of new materials has brought higher performance and longer service life to sheet. For example, carbon fiber composite materials, as a kind of lightweight and high-strength super material, are widely used in the manufacture of sheet. Compared with traditional technical materials, carbon fiber composites have lower density and higher strength-to-weight ratio, which can effectively reduce the weight of sheet and improve the overall performance of mechanical equipment. In addition, carbon fiber composites also have excellent fatigue resistance and corrosion resistance, which can significantly extend the service life of sheet.

It is worth mentioning that the emergence of new materials and technologies not only improves the performance of mechanical equipment, but also promotes the sustainable development of the entire industry. For example, the emergence of some environmentally friendly materials enables sheet to reduce energy consumption and environmental pollution in the manufacturing process. In addition, the application of intelligent technology also helps to improve production efficiency and reduce energy consumption, providing strong support for the green development of the mechanical equipment industry. To sum up, the new materials and technologies of sheet have brought revolutionary changes to the mechanical equipment industry. In the future, with the continuous progress and innovation of science and technology, we have reasons to believe that sheet will play an important role in more fields and promote the sustainable development and progress of the entire industry.

If we have designed one or more sheets, how can we manufacture them quickly and with high quality? When choosing a processing supplier for sheets, we first need to consider the other party's site scale and equipment conditions, and secondly, we need to strictly control the raw materials. Therefore, choosing some suppliers with excellent reputation and strength can enable our workpieces to be processed quickly and with high quality. For example, Richconn has many advantages in the field of sheet processing:

Richconn has advanced gantry equipment for sheet processing, which can quickly process your products.

Richconn has high-precision large-scale inspection equipment to support the quality of sheets.

Richconn's senior technical team can provide valuable suggestions during the design process.

Richconn's superb business team can provide you with all-round consulting services.

To sum up, the importance of sheet in the field of equipment makes it worthy of attention. Because it is valued, it can achieve rapid technological growth. With the continuous development of AI and robotics technologies, I believe we will definitely feel the help that technological updates bring to sheet in the near future.

The Working Principle of CNC Cutting Aluminum SheetsFebruary 29, 2024The Intricacies of CNC Cutting Aluminum SheetsIn the intricate world of manufacturing and fabrication, CNC cutting aluminum sheets has become a cornerstone practice, heralding a new era of precision a...view

The Working Principle of CNC Cutting Aluminum SheetsFebruary 29, 2024The Intricacies of CNC Cutting Aluminum SheetsIn the intricate world of manufacturing and fabrication, CNC cutting aluminum sheets has become a cornerstone practice, heralding a new era of precision a...view How to Remove Chrome Plating Easily? (A Complete Guide 2024)March 11, 2024Learn how to remove chrome plating effectively with our comprehensive guide and get expert tips for successfully stripping chrome from metal surfaces.view

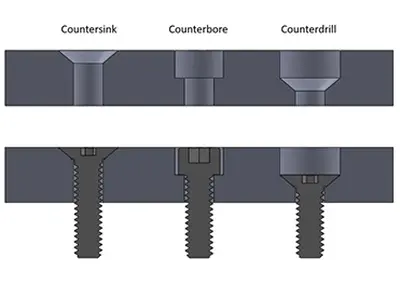

How to Remove Chrome Plating Easily? (A Complete Guide 2024)March 11, 2024Learn how to remove chrome plating effectively with our comprehensive guide and get expert tips for successfully stripping chrome from metal surfaces.view What is Counter Sink? Your Comprehensive GuideOctober 8, 2023A countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material.view

What is Counter Sink? Your Comprehensive GuideOctober 8, 2023A countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material.view CNC Water Jet Cutter: Precision in Cutting TechnologySeptember 28, 2023Have you ever dreamed of achieving flawless precision in cutting materials, from metal to delicate fabrics, with utmost efficiency and accuracy? Your dream can become a reality with the marvel of technology known as the CNC Water Jet Cutter.view

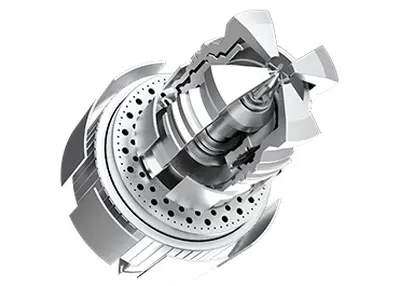

CNC Water Jet Cutter: Precision in Cutting TechnologySeptember 28, 2023Have you ever dreamed of achieving flawless precision in cutting materials, from metal to delicate fabrics, with utmost efficiency and accuracy? Your dream can become a reality with the marvel of technology known as the CNC Water Jet Cutter.view Unleashing Precision: Richconn's CNC Machined Steel ExcellenceNovember 10, 2023Welcome to the realm of precision and durability, where machined steel takes center stage. In this comprehensive exploration, we'll navigate through the intricacies of machined steel, unveil its diverse applications, compare various types, delve into performance metrics, examine Richconn's CNC machining advantages, and provide essential knowledge on mechanical machining.view

Unleashing Precision: Richconn's CNC Machined Steel ExcellenceNovember 10, 2023Welcome to the realm of precision and durability, where machined steel takes center stage. In this comprehensive exploration, we'll navigate through the intricacies of machined steel, unveil its diverse applications, compare various types, delve into performance metrics, examine Richconn's CNC machining advantages, and provide essential knowledge on mechanical machining.view What is CNC Milling Machine: Definition, Uses, Types & PricesMarch 29, 2024Let's delve deeper into CNC milling machine, which holds significant importance for your project, and explore the mill machine in detail.view

What is CNC Milling Machine: Definition, Uses, Types & PricesMarch 29, 2024Let's delve deeper into CNC milling machine, which holds significant importance for your project, and explore the mill machine in detail.view

EN

EN

ru

ru