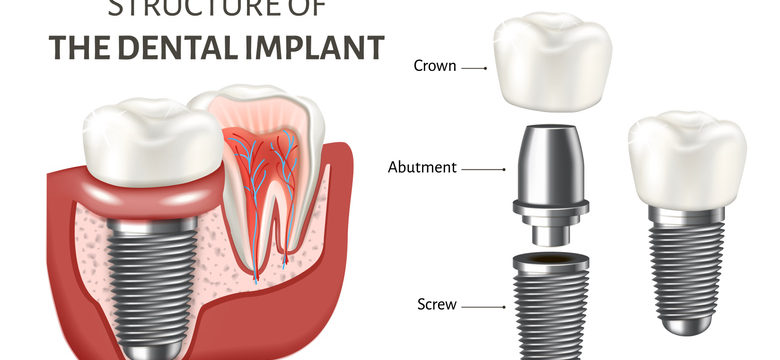

Commonly used implant abutment materials can be divided into five categories: titanium (precision machining, polished, laser etched), surgical grade stainless steel, cast gold alloys, zirconium oxide, and polyether ether ketone (PEEK).

So how to choose the right abutment material in the clinic?

Titanium is the only material that combines toughness, lightness, good biocompatibility and durability with high strength. Titanium has higher corrosion resistance and the highest strength-to-weight ratio than any known element. Titanium abutments are made from industrially pure titanium or titanium alloys. Industrially pure titanium is widely used in medical CNC machining because of its corrosion resistance, strength, and biocompatibility.

Small additions of oxygen and iron can affect the mechanical properties of industrially pure titanium. By strictly controlling the addition of these components, various grades (Grade 1-4) of industrially pure titanium can be produced to fulfill different applications. Industrially pure titanium with the lowest oxygen and iron content is the easiest to machine and form, while gradually increasing the oxygen content improves the strength of the material.

Titanium Alloys (Ti-6Al-4V, Ti6Al4V, or Ti-6-4). Titanium alloys are also known as grade V titanium. Titanium alloys contain 6% aluminum, 4% vanadium, 0.25% (max) iron, 0.2% (max) oxygen, and the rest of the composition is titanium.Ti-6Al-4V alloys are significantly stronger than industrially pure titanium, providing higher tensile strength and fracture resistance.

Titanium abutments are preferred for posterior implant restorations due to their unique physical properties. These abutments can be either pre-fabricated or CAD/CAM milled and customized.

Stainless steel is a special type of stainless steel used in the medical field that contains alloying elements such as chromium, nickel and molybdenum. Stainless steel is easy to clean and sterilize, strong and corrosion resistant. Nickel-chromium-molybdenum alloys are sometimes used for implant abutments, but the immune system has a potential allergic reaction to nickel. Surgical grade stainless steel can be used as a temporary abutment, but is not ideal for restorative abutments.

Cast alloys for implant abutments are composed of 60% to 65% gold, 20% to 25% palladium, 19% platinum and 1% iridium. Recognizing the limitations of the early "finished abutments", implant manufacturers have developed a castable abutment called the UCLA abutment.

Zirconia is a white crystalline form of zirconium oxide. The main form found in nature is the mineral plagioclase with a monoclinic crystal structure. Advances in biomaterials science and ceramics manufacturing technology have led to the use of strong, biocompatible zirconia for biomedical devices and implant abutments. The use of yttrium oxide partially stabilized tetragonal phase polycrystalline zirconia (Y-TZP), powder injection molding (PIM), and hot isostatic pressing (HIP) are hallmarks of zirconia development. Other developments such as the application of alumina-toughened zirconia and cerium-doped zirconia halt the progression of zirconia aging and minimize its effects.

Due to its superior material properties and strength, zirconia can be used for both aesthetic considerations and high loading requirements (e.g., aesthetic zone cases, posterior fixed prosthetic bridges, implant abutments, multi-unit implant restorations). Zirconia has a high flexural strength and fracture toughness, Young's modulus, similar to steel. In addition to strength, the greatest advantage of zirconia is the superior tissue integration. Various studies have confirmed the success of zirconia abutments in maintaining soft tissue and marginal bone stability. The results indicate that the abutment material type influences the amount and texture of the surrounding tissue (zirconia vs. cast gold alloy). In addition, the zirconia abutment greatly reduced bacterial and plaque adherence and prevented soft tissue inflammation.

PEEK has become the most popular material for temporary abutments. It is a beige or white organic polymer and crystalline thermoplastic with excellent mechanical properties and corrosion resistance. The Young's modulus is 3.6 GPa and the tensile strength is 90 to 100 MPa. It has a high resistance to thermal degradation, as well as resistance to attack by organics and moisture.

These strong properties make PEEK the perfect material for temporary abutments. As early as 1987, animal studies conducted by Williams et al. demonstrated the biocompatibility of PEEK materials. 1995, Hunter et al. used PEEK, titanium, and chromium cobalt (CoCr) in orthopedic surgery and compared them; no differences were found between the three in the attachment of fibroblasts or osteoblasts.

In dentistry, PEEK polymers are used for restorative abutments and healing abutments; PEEK abutments are the preferred choice for temporary restorative abutments or healing abutments. Although research on PEEK polymers is currently limited, its applications are promising.

Ten Questions and Answers About Stainless Steel Valves: Unlocking the Secrets of Check ValvesAugust 11, 2023IntroductionIn this comprehensive article, we will delve deep into the mysteries of stainless steel valves, with a particular focus on the working principles and applications of check valves across di...view

Ten Questions and Answers About Stainless Steel Valves: Unlocking the Secrets of Check ValvesAugust 11, 2023IntroductionIn this comprehensive article, we will delve deep into the mysteries of stainless steel valves, with a particular focus on the working principles and applications of check valves across di...view Understanding the Properties of Anodizing Process in One ReadingApril 4, 2023Nowadays, the use of metal technology is quite popular, and many machines in the market have large metal parts. One of the surface treatment processes for metal is anodizing, which is very commonly us...view

Understanding the Properties of Anodizing Process in One ReadingApril 4, 2023Nowadays, the use of metal technology is quite popular, and many machines in the market have large metal parts. One of the surface treatment processes for metal is anodizing, which is very commonly us...view What Industries Use Stainless Steel?October 27, 2023Stainless steel is the abbreviation of stainless and acid-resistant steel, air, steam, water and other weak corrosive media or with stainless steel is called stainless steel, and will be resistant to chemical corrosive media (acids, alkalis, salts and other chemical corrosion) corrosion of the steel is called acid-resistant steel.view

What Industries Use Stainless Steel?October 27, 2023Stainless steel is the abbreviation of stainless and acid-resistant steel, air, steam, water and other weak corrosive media or with stainless steel is called stainless steel, and will be resistant to chemical corrosive media (acids, alkalis, salts and other chemical corrosion) corrosion of the steel is called acid-resistant steel.view Precautions for Stamping Dies 1July 11, 2023Spring compression and calculationIn a set of stamping dies, more elastic materials need to be used, including springs of different specifications, urethane, nitrogen springs, etc., and different elas...view

Precautions for Stamping Dies 1July 11, 2023Spring compression and calculationIn a set of stamping dies, more elastic materials need to be used, including springs of different specifications, urethane, nitrogen springs, etc., and different elas...view Tips On How to Find Low Cost CNC Milling ServicesOctober 24, 2023CNC milling services are not cheap. The more accurate the design you need, the more money you can expect to spend. Reliable machine shops employ professional operators who use state-of-the-art equipment to fulfill orders. As a result, you can't afford to ignore your budget in order to shorten lead times or gain a competitive edge.view

Tips On How to Find Low Cost CNC Milling ServicesOctober 24, 2023CNC milling services are not cheap. The more accurate the design you need, the more money you can expect to spend. Reliable machine shops employ professional operators who use state-of-the-art equipment to fulfill orders. As a result, you can't afford to ignore your budget in order to shorten lead times or gain a competitive edge.view What Is Galvanized Sheet Metal? The Complete Basics to Get StartedOctober 12, 2023Galvanized sheet metal is one of the most cost-effective and popular types of metal in the market. Here are the complete basics about it for you to get started.view

What Is Galvanized Sheet Metal? The Complete Basics to Get StartedOctober 12, 2023Galvanized sheet metal is one of the most cost-effective and popular types of metal in the market. Here are the complete basics about it for you to get started.view

EN

EN

ru

ru