Casting has played a vital role in the development of human civilization. This technique, involving the pouring of liquid material into a mold with a desired hollow shape, has been instrumental in creating a diverse array of products, ranging from simple tools and weapons to intricate machinery and components. Among various types of casting, such as sand casting, investment casting, and die casting, this age-old process continues to be a cornerstone in the production of a wide range of items.

Among the array of casting methods, several stand out for their unique applications and characteristics.

Sand casting, a time-honored technique dating back millennia, stands as the oldest and most pervasive casting method. This method's enduring legacy is evident in its application for crafting substantial components like engine blocks, pipes, and manhole covers. The process begins by shaping a mold from sand, into which molten metal is poured. After cooling and solidifying, the removal of the sand mold reveals the final product.

Known as lost-wax casting, investment casting emerges as a sophisticated process tailored for intricate parts with fine details. This type of casting initiates with the creation of a wax pattern, coated in ceramic, and the subsequent melting of the wax to form a mold. Molten metal is then meticulously poured into the mold, resulting in the creation of intricate designs and complex geometries. Investment casting's prowess lies in its ability to produce finely detailed components.

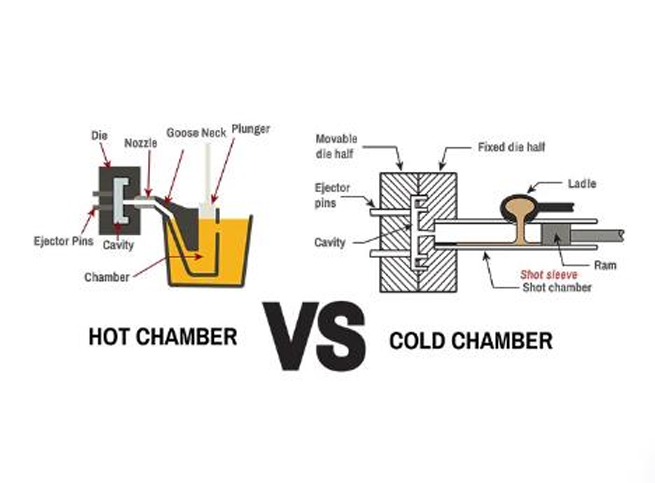

Die casting is a go-to type of casting in the automotive and electronics sectors, it is a hallmark of precision engineering. This technique ensures not only high dimensional accuracy but also a smooth surface finish. The die casting process involves injecting molten metal into a mold under high pressure, with two prominent variations—hot chamber die casting and cold chamber die casting.

Hot Chamber Die Casting

In hot chamber die casting, the machine houses a pool of molten metal, channeling it into the die through a gooseneck and piston. This streamlined process is particularly adept with metals boasting lower melting points, such as zinc and magnesium. Recognized for its efficiency, hot chamber die casting excels in high-volume production, ensuring rapid turnaround times.

Cold Chamber Die Casting

Cold chamber die casting diverges by having the molten metal poured into a separate chamber before injection into the die through a hydraulic or mechanical piston. While inherently slower than its hot chamber counterpart, cold chamber die casting compensates with the ability to handle metals with higher melting points, like aluminum and copper alloys. This method prioritizes quality and dimensional accuracy, making it an indispensable choice for critical applications.

Moving beyond casting techniques, understanding the nuances of cast iron is crucial for diverse applications. Cast iron, a common material used in the casting process, also comes in different types.

Gray Cast Iron

Widely used due to its good wear resistance and machinability, gray cast iron finds its place in pipes, machine tool structures, and automotive parts.

White Cast Iron

Boasting high hardness and brittleness, white cast iron shines in applications requiring exceptional wear resistance, such as in wear-resistant surfaces and grinding balls.

Ductile Cast Iron

Recognized for its flexibility and ductility, ductile cast iron is preferred for applications demanding high strength and toughness, including crankshafts, gears, and hydraulic cylinders.

Malleable Cast Iron

Achieved through heat treatment, malleable cast iron offers enhanced ductility and toughness, making it suitable for applications requiring strength and malleability, such as pipe fittings and hand tools.

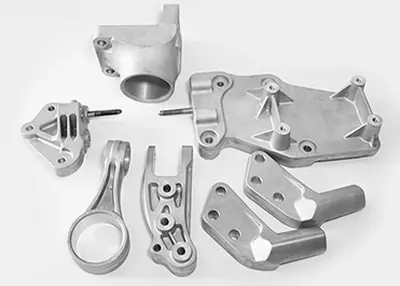

With cast iron's rich properties, the casting process allows for the production of complex shapes and intricate details, making cast iron a popular choice in industries such as automotive, construction, and manufacturing. Different types of casting and different types of cast iron find applications across various industries.

Automotive

Casting techniques are pivotal in crafting durable engine blocks, cylinder heads, and transmission cases, meeting the automotive industry's precision and durability standards.

Aerospace

Castings play a critical role in aerospace applications, especially in the manufacturing of intricate components like turbine blades for aircraft engines. Casting ensures the necessary strength and reliability under extreme conditions, advancing aviation technology.

Construction

Cast iron's durability is one of its key advantages in construction, providing longevity and resilience. Used in pipes and manhole covers, cast iron components withstand challenging environmental conditions, contributing to the robustness of infrastructure projects.

The casting process involves several potential hazards, making it crucial to implement thorough safety protocols.

Workers engaged in the casting process should be equipped with a comprehensive set of protective gear to mitigate risks. This includes:

Gloves: Heat-resistant gloves are crucial to protect against burns from molten metal.

Safety Glasses: Safety glasses shield the eyes from any splashes, sparks, or other debris that may be generated during the casting process.

Face Shields: In situations where there is a higher risk of larger debris or splashes, face shields provide an added layer of protection for the face and neck.

Heat-Resistant Clothing: Workers should wear heat-resistant clothing to protect against radiant heat and potential splashes.

The casting process often involves the release of fumes and gases that can be harmful if inhaled. Implementing proper ventilation systems helps in:

Fume Extraction: Local exhaust systems can be employed to capture and remove fumes at the source, preventing their dispersion into the workspace.

General Ventilation: Ensuring good overall ventilation in the workspace helps disperse any residual fumes, maintaining air quality.

Personal Respirators: In situations where fumes may still pose a risk, providing workers with personal respirators adds an extra layer of protection.

Worker training is a foundation for creating a safe working environment in casting facilities. Training programs are recommended to include:

Molten Metal Handling: Workers should be well-versed in the proper techniques for handling molten metal, understanding the risks and necessary precautions.

Emergency Procedures: This includes protocols for responding to accidents, fires, or other unforeseen events.

First Aid Training: Ensuring that workers are trained in basic first aid can make a significant difference in the immediate response to any injuries or accidents.

Considering the inherent risks involved in casting operations, businesses can strategically mitigate potential hazards by outsourcing these complex tasks to specialized machining companies.

Richconn, a leading professional machining company, helps you better handle your casting projects easily!

Richconn excels in providing comprehensive casting solutions with a strong emphasis on safety and precision. With advanced technologies and a highly skilled workforce, they ensure the efficient and secure execution of casting processes. By entrusting casting operations to Richconn, businesses not only minimize risks but also benefit from the company's commitment to delivering high-quality results.

Choosing the right casting type comes with knowing the kinds of casting used nowadays. Only if you can choose the right type of casting, can you get the ideal project performance. Do you have a product, and you worry about making it functional? Why not contact Richconn today? It provides cost-effective and versatile solutions for producing complex and high-quality components.

Discover the perfect casting services for your needs online now!

Click here ↓↓↓

Aluminum Alloy Anodic Oxidation Common ProblemsOctober 23, 2023Anodizing is one of the most common metal surface treatment operations performed on aluminum parts. It is an electrochemical process that involves immersing aluminum parts in a series of tanks to transform the aluminum surface into a durable and corrosion-resistant finish.view

Aluminum Alloy Anodic Oxidation Common ProblemsOctober 23, 2023Anodizing is one of the most common metal surface treatment operations performed on aluminum parts. It is an electrochemical process that involves immersing aluminum parts in a series of tanks to transform the aluminum surface into a durable and corrosion-resistant finish.view 4140 Steel: A Versatile Alloy with Excellent PropertiesDecember 7, 2023Steel is one of the most widely used materials in the world, thanks to its strength, durability, and versatility. However, not all steel grades are the same. Depending on the chemical composition and the heat treatment, different steel grades can have different properties and applications.view

4140 Steel: A Versatile Alloy with Excellent PropertiesDecember 7, 2023Steel is one of the most widely used materials in the world, thanks to its strength, durability, and versatility. However, not all steel grades are the same. Depending on the chemical composition and the heat treatment, different steel grades can have different properties and applications.view What Are the Methods of Testing the Properties of Metallic Materials?October 26, 2023Tensile testing is a common method of evaluating the strength and ductility of materials. It involves placing a specimen in a tensile testing machine, gradually applying a tensile force, measuring the stress-strain curve and determining the yield strength, tensile strength, and elongation of the material.view

What Are the Methods of Testing the Properties of Metallic Materials?October 26, 2023Tensile testing is a common method of evaluating the strength and ductility of materials. It involves placing a specimen in a tensile testing machine, gradually applying a tensile force, measuring the stress-strain curve and determining the yield strength, tensile strength, and elongation of the material.view Machining Tungsten Guide: Can Tungsten be Machined?November 13, 2023Welcome to the cutting-edge world of machining tungsten, where precision meets excellence. As the forefront player in CNC machining, Richconn is here to unravel the intricacies of working with tungsten, answering the pivotal question: Can tungsten be machined?view

Machining Tungsten Guide: Can Tungsten be Machined?November 13, 2023Welcome to the cutting-edge world of machining tungsten, where precision meets excellence. As the forefront player in CNC machining, Richconn is here to unravel the intricacies of working with tungsten, answering the pivotal question: Can tungsten be machined?view Top 10+ Must-have Machinist ToolsFebruary 26, 2024Understanding the right machinist tools can boost productivity. This article highlights three essential tool categories.view

Top 10+ Must-have Machinist ToolsFebruary 26, 2024Understanding the right machinist tools can boost productivity. This article highlights three essential tool categories.view What Is A Coordinate Measuring Machine Used For?July 16, 2024A coordinate measuring machine is often used to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about it to ensure every part you make meets and exceeds your expectations.view

What Is A Coordinate Measuring Machine Used For?July 16, 2024A coordinate measuring machine is often used to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about it to ensure every part you make meets and exceeds your expectations.view

EN

EN

ru

ru