Tensile testing is a common method of evaluating the strength and ductility of materials. It involves placing a specimen in a tensile testing machine, gradually applying a tensile force, measuring the stress-strain curve and determining the yield strength, tensile strength, and elongation of the material.

The tensile test is one of the most widely used mechanical property test methods for metallic materials, in which a load is slowly applied to both ends of a specimen loaded in a testing machine, so that the working part of the specimen is subjected to axial tensile load along the axial elongation until it is pulled off. Determination of the resistance of the specimen to the applied load, you can find out the strength of the material evidence, determination of the specimen in the plastic deformation after pulling off, you can find out the plasticity of the material evidence.

Using the data obtained from the tensile test can determine the basic mechanical properties of the material indicators, strength indicators such as the elastic limit, yield strength and tensile strength; plasticity indicators such as elongation at break, section shrinkage.

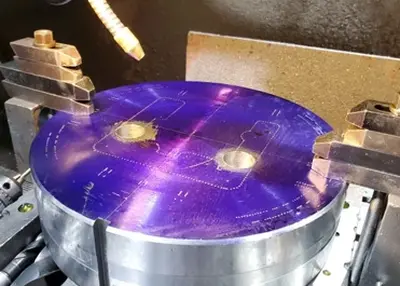

Hardness testing is used to evaluate the compression and scratch resistance of a material. Common hardness testing methods include Brinell hardness testing, Vickers hardness and micro hardness testing. Vickers hardness test for uniform hardness of the material can be arbitrarily selected test force, its hardness value remains unchanged.

Test fracture toughness test is a test to assess the fracture performance of crack-containing body materials. Strength concept that: the external force reaches the yield strength, the material produces plastic deformation, the external force reaches the tensile strength Rm, the material produces fracture damage, for the crack-containing body material, it produces a brittle fracture below the yield strength. Fracture toughness is a kind of energy as the basic parameter of performance indicators, it and the state and depth of cracks within the material is closely related, it can provide quantitative performance indicators for the crack-containing body materials. Commonly used test methods include impact tests (e.g., impact bending tests and impact notch tests), in which the toughness of a material is evaluated by measuring the energy of fracture.

Metallographic microscopy analysis is the observation of the organizational structure and phase transformations of a metallic material through an optical microscope. This method of analysis provides information on grain size, crystal structure, phase content and defects to assess the lattice structure and treatment of the material.

Fatigue damage is the fracture of a material after a certain number of cycles under alternating stresses below the tensile strength, i.e., there is no significant plastic deformation prior to fracture. Fatigue life testing is used to assess the durability of metallic materials under alternating stress. Commonly used methods include rotational bending fatigue test, tensile fatigue test and vibration fatigue test.

Corrosion testing is used to evaluate the corrosion resistance of metallic materials under specific environmental conditions. Common corrosion test methods include salt spray test, galvanic corrosion test and immersion test.

Richconn, your creative wing! As a leading rapid prototyping company in China, we provide you with exceptional metal CNC machining services and sheet metal services. No matter the size of your project, we are committed to creating a high quality, customized solution for you. Partner with Richconn to quickly bring your ideas to life!

Understanding CNC Manufacturing CostsOctober 11, 2023A common question asked is, "How much will it cost me and how much will it cost to manufacture?" Everyone loves a bargain! Plus, we can judge the prices of our daily purchases - €5 for a liter of milk? No way!"view

Understanding CNC Manufacturing CostsOctober 11, 2023A common question asked is, "How much will it cost me and how much will it cost to manufacture?" Everyone loves a bargain! Plus, we can judge the prices of our daily purchases - €5 for a liter of milk? No way!"view Beyond Aesthetics: The Practical Benefits of Blackening Surface TreatmentDecember 4, 2023When it comes to surface treatments for various metal components, one often thinks about aesthetics and corrosion resistance as the primary goals. However, there is another important surface treatment...view

Beyond Aesthetics: The Practical Benefits of Blackening Surface TreatmentDecember 4, 2023When it comes to surface treatments for various metal components, one often thinks about aesthetics and corrosion resistance as the primary goals. However, there is another important surface treatment...view Better CNC Parts Through Fine tuning of TolerancesOctober 13, 2023Tolerances that are too tight can require rework, which in turn drives up costs. If tolerances are too loose, the part may not fit with the mating part. So to optimize your designs, know what tolerances are needed and when: Standard tolerances can improve quality, ensure fast repeatability and reduce manufacturing costs.view

Better CNC Parts Through Fine tuning of TolerancesOctober 13, 2023Tolerances that are too tight can require rework, which in turn drives up costs. If tolerances are too loose, the part may not fit with the mating part. So to optimize your designs, know what tolerances are needed and when: Standard tolerances can improve quality, ensure fast repeatability and reduce manufacturing costs.view How to Find the Right Manufacturing PartnerOctober 13, 2023It’s worth taking the time to find a supplier that’s a perfect fit for the buyer’s company. Think of it as a partnership in which both parties are committed and invested. In the digital age, it is increasingly advisable to also consider additional total cost of ownership (TCO) savings.view

How to Find the Right Manufacturing PartnerOctober 13, 2023It’s worth taking the time to find a supplier that’s a perfect fit for the buyer’s company. Think of it as a partnership in which both parties are committed and invested. In the digital age, it is increasingly advisable to also consider additional total cost of ownership (TCO) savings.view From Start-up to Llarge ManufacturerOctober 10, 2023As a manufacturing startup, your success story starts with proving that your product is marketable. When you prepare for large-scale production, it determines the success or failure of the company, because it is in this situation that you have to invest a lot of money and determine the future direction.view

From Start-up to Llarge ManufacturerOctober 10, 2023As a manufacturing startup, your success story starts with proving that your product is marketable. When you prepare for large-scale production, it determines the success or failure of the company, because it is in this situation that you have to invest a lot of money and determine the future direction.view What Is Extruded Aluminum And How Does It Work?February 1, 2024Aluminum extrusion has been increasingly popular in making many types of products. What is aluminum extrusion? How does it work? Read this article about the extrusion process.view

What Is Extruded Aluminum And How Does It Work?February 1, 2024Aluminum extrusion has been increasingly popular in making many types of products. What is aluminum extrusion? How does it work? Read this article about the extrusion process.view

EN

EN

ru

ru