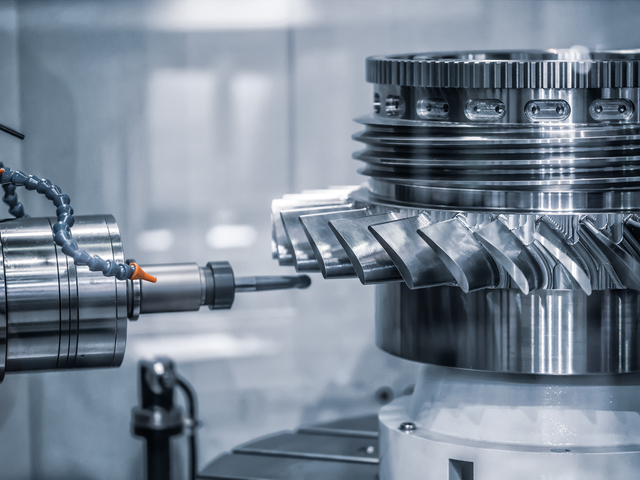

CNC machining is one of the most widely used manufacturing methods in the aerospace industry. While you probably know at least a little about it, here are 8 things you need to know when CNC machining aerospace parts.

Aluminum and titanium are the most commonly used metals in aircraft due to their strength. With that in mind, you may be wondering why these materials are more commonly used than steel - after all; it's stronger and cheaper than aluminum and comparable to titanium in terms of strength.

It all comes down to the fact that these metals are lighter than steel.

Titanium is just as strong as steel, but 45% lighter, while aluminum is about 33% lighter. These lightweight metals help improve the fuel economy and overall efficiency of an airplane. But here's the catch: they're often difficult to machine manually.

CNC machinery is compatible with a wide range of materials and is highly dependent on the manufacturing process.

R&D is a critical function of the aerospace industry, and CNC machining is at the forefront of this process. Because CNC machines rely on 3D CAD models and computer instructions to create parts, aerospace engineers can quickly create new prototype designs, test them, and edit them when needed.

CNC rapid prototyping requires no investment in tooling, so it can help aerospace companies minimize costs and expenses. What's more, it can help aerospace companies meet regulatory requirements such as ISO 9001:2015 and AS9001 standards.Richconn is a cnc machining company in China, founded in 2008, we have 16 years of experience in CNC machining and manufacturing, and our quality certifications are very complete.

Aerospace part designs are becoming increasingly complex. For example, NASA's Orion bulkheads (the part that keeps the crew safe during their journey) are domed near the heat shield and feature pockets perpendicular to its surface. In addition, the landing gear and fuselage sections of the airplane are huge, feature minute details, and require extremely tight machining tolerances.

5-axis CNC machining can be used to machine these complex parts. They can realize the range and angle that is impossible to achieve using 3-axis or 4-axis machines.

Modern CNC machines used in the aerospace industry are now equipped with artificial intelligence (AI) and machine learning software. This allows aerospace companies to see accurate production metrics and achieve aerospace part production goals. The technology also improves the quality and consistency of machined aerospace parts.

The use of high-quality materials is critical for aerospace parts to withstand extreme conditions such as temperature variations, high pressures and tremendous forces. These materials include aluminum alloys, titanium alloys, stainless steel and carbon fiber composites, which offer excellent properties such as heat and corrosion resistance and high strength-to-weight ratios, making them ideal for aerospace applications.

CNC machining plays a key role in accurately and efficiently machining these advanced materials to meet the stringent requirements of the aerospace industry. Therefore, the selection of quality materials through stringent quality control measures positively impacts the overall quality of the final product.

Custom CNC machining minimizes waste while streamlining the production process, thus helping to reduce the cost of manufacturing aerospace products. CNC machines can produce complex parts faster than traditional methods without compromising accuracy.

This accuracy increases productivity while reducing labor costs due to shorter production cycles. This ability to produce high precision parts relatively quickly is an important factor in reducing overall manufacturing costs.

The short time required to produce high precision parts significantly reduces manufacturing costs as optimizing material usage minimizes waste, resulting in a sustainable and cost-effective manufacturing process that aids in cost management - an important factor in this industry.

Maintenance and quality control are key aspects of aerospace CNC machining. Regular maintenance of CNC machine tools ensures optimal performance, extends service life and prevents unplanned downtime. By performing routine inspections, calibrations and cleaning, manufacturers can maintain the accuracy and efficiency of their CNC machines.

Quality control is equally important in aerospace CNC machining to ensure that each part meets the required specifications and tolerances. Manufacturers can identify and correct errors by implementing rigorous inspection protocols before moving to the assembly stage.

Advanced technologies such as coordinate measuring machines (CMMs), laser scanning, and computer vision systems are often used to ensure the accuracy of machined parts.

Technology is continuing to evolve and innovate at an alarming rate. Manufacturers must keep up with these trends to compete. Several important trends may drive the future of CNC machining in the aerospace industry:

Additive manufacturing: combining additive manufacturing (3D printing) with traditional CNC machining will enable the production of complex parts with unique geometries that were previously impossible or too expensive to manufacture.

Smart Manufacturing: The use of Industry 4.0 technologies, such as IoT devices, will allow for real-time monitoring, data collection and analysis during CNC machining. This will allow manufacturers to optimize operations, improve quality control and reduce waste.

Digital twins: Creating digital replicas of physical CNC machines to analyze and optimize their performance is another technology that is receiving attention. This process can facilitate more efficient machine setups, preventive maintenance and remote troubleshooting.

These trends will continue to influence CNC machining in the aerospace industry, driving future innovation and efficiency.

Nothing is more important in aerospace parts machining than precision, and like companies in other industries, aerospace companies rely on many third-party manufacturers to produce different parts. These parts often require tight tolerances and must fit correctly with parts made by other machine shops. As a result, there are no geometric errors in the manufacturing process.

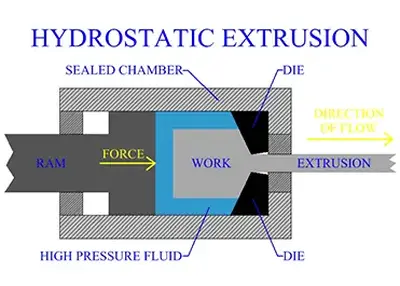

Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view

Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view What Is CNC Process? CNC Machining Process Design PrinciplesMarch 6, 20231, the maximum concentration of CNC machining process, a positioning principleGenerally in the CNC machine tools, especially in the machining center on the processing parts, the process can be maximal...view

What Is CNC Process? CNC Machining Process Design PrinciplesMarch 6, 20231, the maximum concentration of CNC machining process, a positioning principleGenerally in the CNC machine tools, especially in the machining center on the processing parts, the process can be maximal...view Learn More About Manufacturing Options For Elastomeric ComponentsOctober 18, 2023Materials scientists like to give their creations complicated names. Polyethylene terephthalate (a form of polyester). Acrylonitrile butadiene styrene (this opaque thermoplastic is better known as ABS). These are just two examples of the thousands of polymers in use today. Many of them have fundamentally changed our lives.view

Learn More About Manufacturing Options For Elastomeric ComponentsOctober 18, 2023Materials scientists like to give their creations complicated names. Polyethylene terephthalate (a form of polyester). Acrylonitrile butadiene styrene (this opaque thermoplastic is better known as ABS). These are just two examples of the thousands of polymers in use today. Many of them have fundamentally changed our lives.view CNC Motion Control and Three Common TypesOctober 20, 2023Many CNC machines can be left unattended throughout the machining cycle, freeing the operator for other tasks. This benefit allows CNC users to provide several side effects, including reduced operator fatigue, errors due to operator error, and consistent and predictable machining times for each workpiece.view

CNC Motion Control and Three Common TypesOctober 20, 2023Many CNC machines can be left unattended throughout the machining cycle, freeing the operator for other tasks. This benefit allows CNC users to provide several side effects, including reduced operator fatigue, errors due to operator error, and consistent and predictable machining times for each workpiece.view How long does it take to CNC machine a simple part?November 1, 2023CNC machining, as an important process in the modern manufacturing field, has been widely used in various industries to realize the manufacturing of precision parts through the intelligent control of computers. In the manufacturing process, the complexity of the part has a great impact on the machining time. In this paper, we will discuss the time required for CNC machining from the perspective of simple geometry to highly complex structures, and analyze in depth the influence of geometry, machining process and related parameters on machining time.view

How long does it take to CNC machine a simple part?November 1, 2023CNC machining, as an important process in the modern manufacturing field, has been widely used in various industries to realize the manufacturing of precision parts through the intelligent control of computers. In the manufacturing process, the complexity of the part has a great impact on the machining time. In this paper, we will discuss the time required for CNC machining from the perspective of simple geometry to highly complex structures, and analyze in depth the influence of geometry, machining process and related parameters on machining time.view CNC Machined Billet Aluminum: Unveiling Precision in ManufacturingNovember 13, 2023Welcome to the realm of precision engineering, where CNC Machined Billet Aluminum takes center stage. As the proud provider of CNC machining services, Richconn stands as your gateway to unrivaled expertise and cutting-edge solutions in the realm of aluminum machining. Let's delve into the intricacies of CNC machining and the unparalleled advantages offered by billet aluminum.view

CNC Machined Billet Aluminum: Unveiling Precision in ManufacturingNovember 13, 2023Welcome to the realm of precision engineering, where CNC Machined Billet Aluminum takes center stage. As the proud provider of CNC machining services, Richconn stands as your gateway to unrivaled expertise and cutting-edge solutions in the realm of aluminum machining. Let's delve into the intricacies of CNC machining and the unparalleled advantages offered by billet aluminum.view

EN

EN

ru

ru