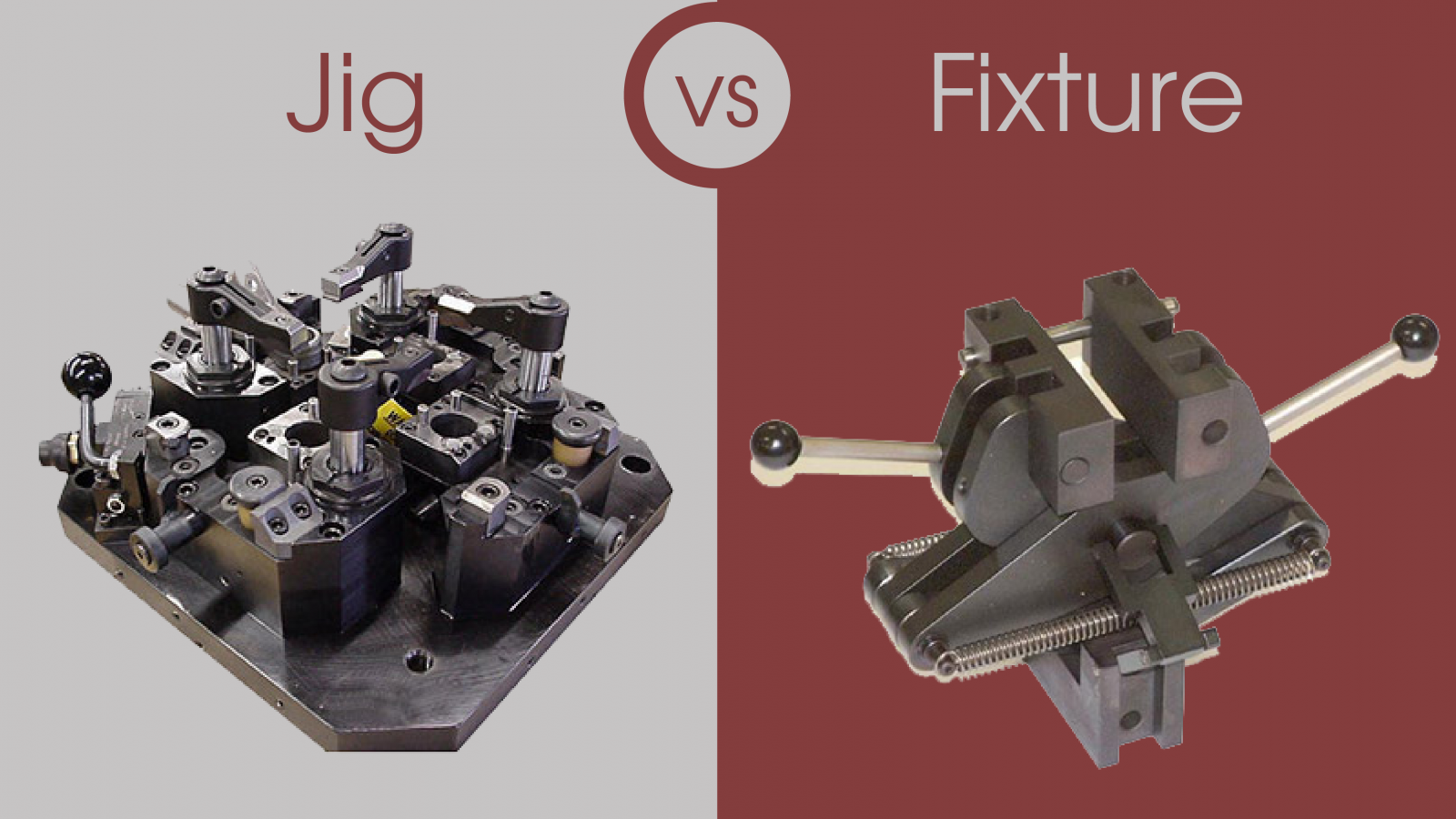

Jig vs Fixture is a common topic in manufacturing and engineering. Jigs and fixtures are two types of devices that are used to hold, support, and locate workpieces during machining or assembly processes. However, they have some differences in their design, function, and application.

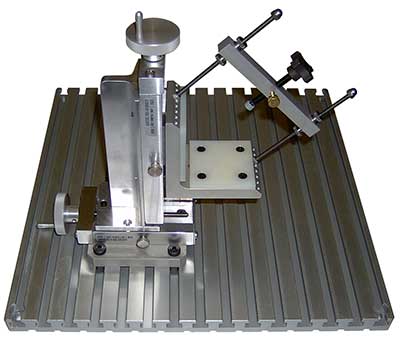

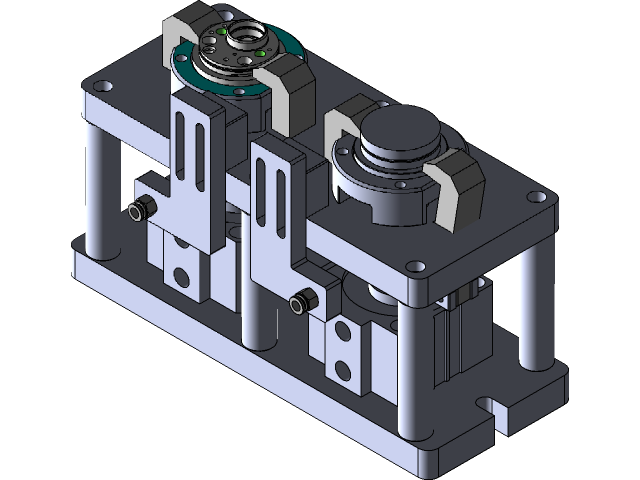

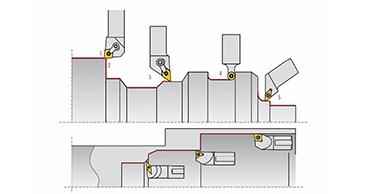

A jig is a device that holds and locates a workpiece and guides and controls one or more cutting tools. A jig is used to provide repeatability, accuracy, and interchangeability in the manufacturing of products. There are different types of jigs, such as drilling jigs, milling jigs, boring jigs, etc., depending on the operation they perform. A jig usually has bushings or pins that align with the holes or features to be machined on the workpiece, and provides both clamping and locating functions. A jig is typically lighter than a fixture, which is another type of workholding device that does not guide the tool. A jig is mainly used for drilling, reaming, tapping, and boring operations, while a fixture is mainly used for milling, turning, grinding, and welding operations.

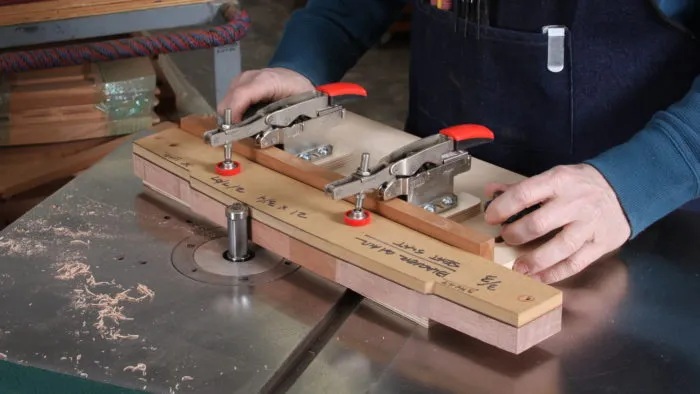

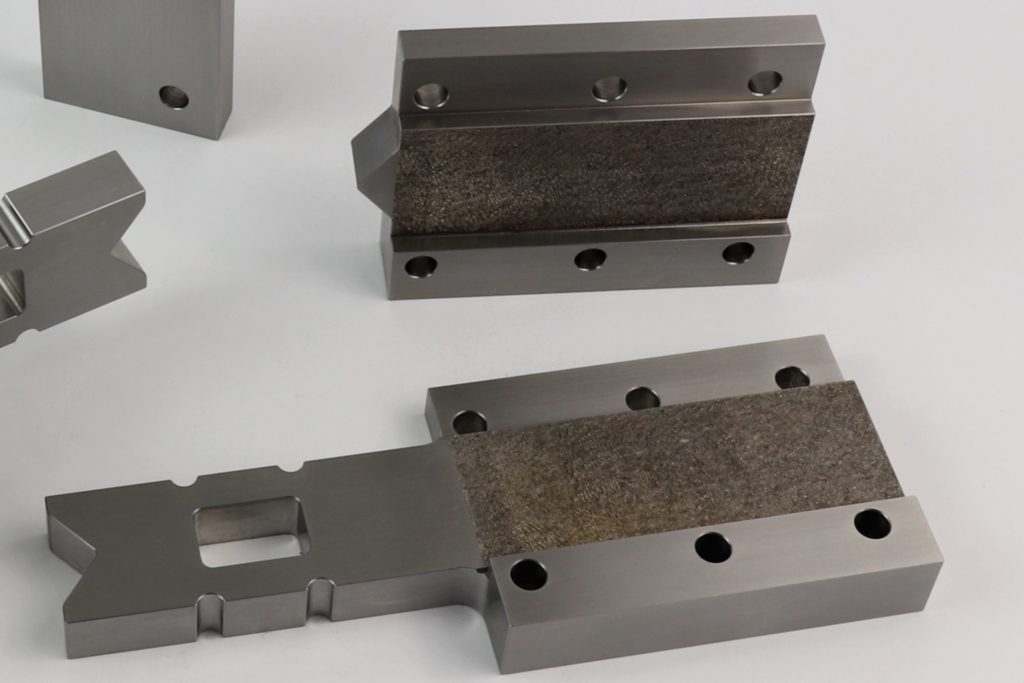

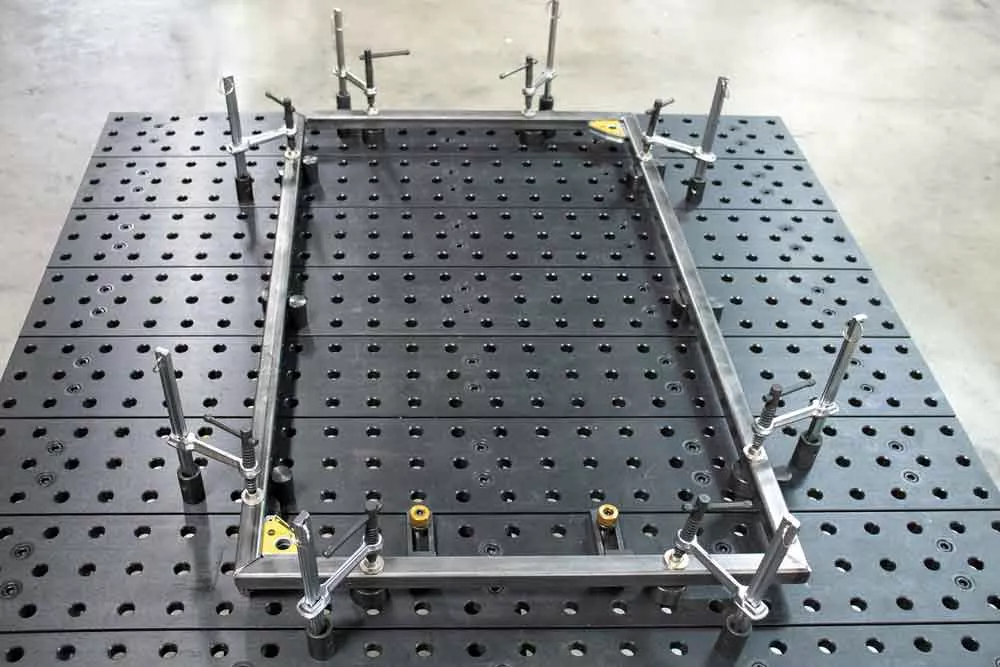

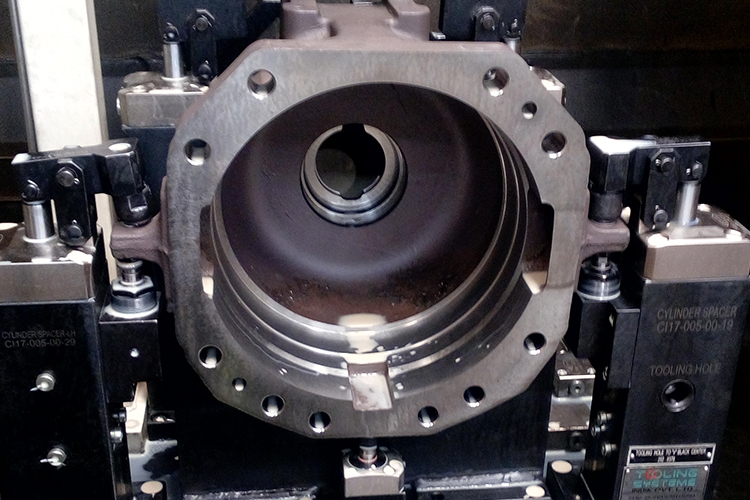

A fixture is a device that holds and supports a workpiece during a machining or assembly process. A fixture does not guide the tool, but only positions and clamps the workpiece. A fixture is different from a jig, which is another type of workholding device that guides the tool to a predefined location on the workpiece. A fixture is usually heavier than a jig, and needs to withstand the cutting force and vibration. A fixture is mainly used for milling, turning, grinding, and welding operations, while a jig is mainly used for drilling, reaming, tapping, and boring operations. There are different types and classifications of fixtures, such as open, closed, universal, modular, adjustable, hydraulic, pneumatic, magnetic, etc. They also have different elements and components, such as body, locating elements, clamping elements, and guiding elements. The design of fixtures depends on several principles and considerations, such as accuracy, rigidity, simplicity, economy, and safety.

Jigs are used to provide repeatability, accuracy, and interchangeability in the manufacturing of products. There are different types of jigs, depending on the shape and size of the workpiece, the direction of the material flow, and the complexity of the operation.

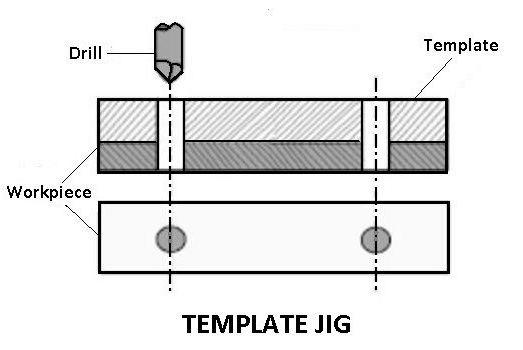

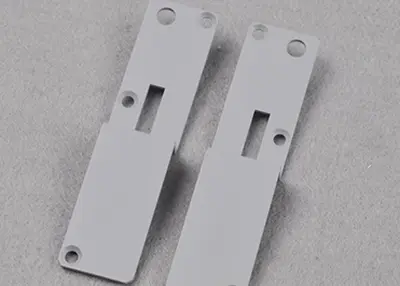

Template jigs are the simplest and most basic type of jigs, where the jig consists of a thin plate or sheet that has the same shape and size as the workpiece. The jig is placed over the workpiece and clamped to it, and it has holes or slots that guide the tool to work at the desired location on the workpiece. Template jigs are suitable for workpieces that have simple and flat shapes, such as plates, sheets, or disks. Template jigs are also suitable for workpieces that have low accuracy and precision requirements, such as rough machining or drilling operations.

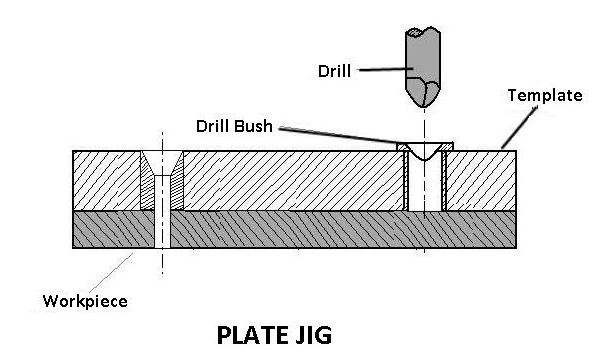

Plate jigs are similar to template jigs, but they are thicker and heavier, and they have more components and features, such as bushings, pins, and clamps, that help to locate and secure the workpiece and the tool. Plate jigs are placed under the workpiece and clamped to it, and they have holes or slots that guide the tool to work at the desired location on the workpiece. Plate jigs are suitable for workpieces that have moderate and complex shapes, such as boxes, frames, or housings. Plate jigs are also suitable for workpieces that have medium accuracy and precision requirements, such as semi-finished machining or boring operations.

These are similar to plate jigs except that they have legs to raise the jig off the table for large workpieces. They are used for machining heavy and bulky parts.

These are used for drilling thin or soft parts to avoid bending, warping, or distortion. They have a support plate at the bottom and a top jig that is located by using locating pins. The workpiece is sandwiched between the two plates.

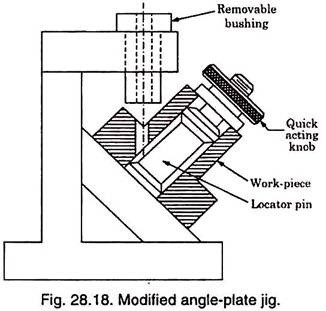

Angle-plate jigs are a type of plate jigs, but they have an angled or vertical plate that supports the workpiece and allows the tool to work on the vertical or inclined surface of the workpiece. Angle-plate jigs are placed under the workpiece and clamped to it, and they have holes or slots that guide the tool to work at the desired location on the workpiece. Angle-plate jigs are suitable for workpieces that have irregular and angular shapes, such as brackets, flanges, or fittings. Angle-plate jigs are also suitable for workpieces that have special accuracy and precision requirements, such as milling or tapping operations.

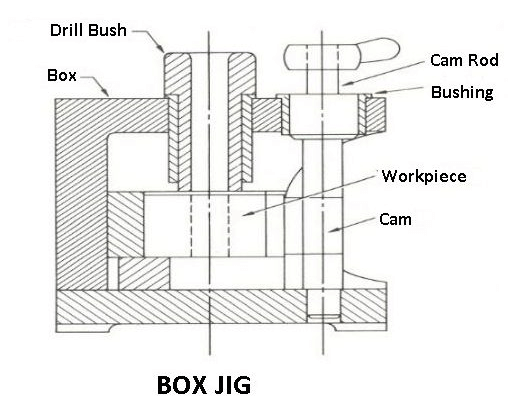

These are used to completely surround the workpiece and drill holes from all sides. They have a box-type structure that has bushings or pins on its inner walls. They are used for machining complex and irregular-shaped parts.

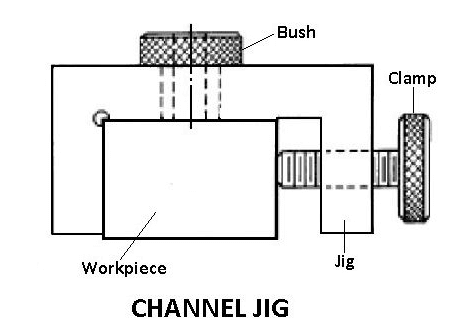

These are the simplest form of box jigs that have an open top and a channel-shaped body. They are placed over the workpiece and located by one side of the work and clamped from the other side. They are used for machining long and narrow parts.

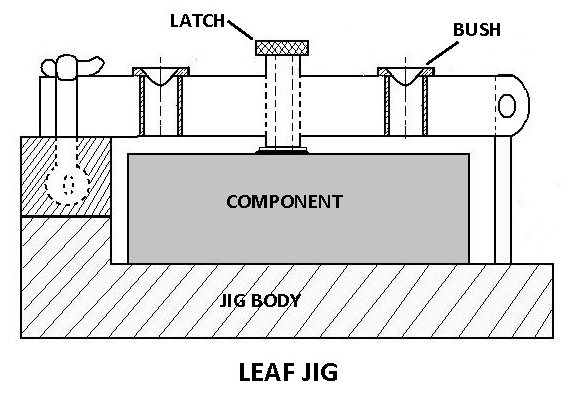

Leaf jigs are a type of plate jigs, but they have one or more movable plates or leaves that can be opened or closed to facilitate the loading and unloading of the workpiece. Leaf jigs are placed under the workpiece and clamped to it, and they have holes or slots that guide the tool to work at the desired location on the workpiece. Leaf jigs are suitable for workpieces that have large and heavy shapes, such as castings, forgings, or weldments. Leaf jigs are also suitable for workpieces that have high accuracy and precision requirements, such as finished machining or reaming operations.

These are used to accurately space holes or other machined areas around a part. They have a reference plate and a plunger that are used to rotate the workpiece to the desired position. They are used for machining gears, sprockets, flanges, etc.

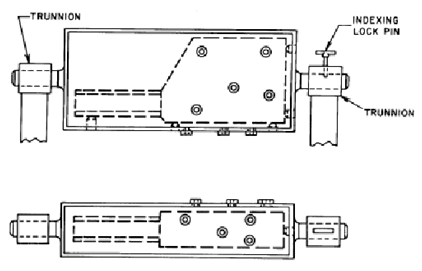

These are used for drilling holes on very large or odd-shaped parts from different sides. They have a box-type carrier that holds the workpiece and a trunnion that supports the carrier and allows it to rotate. They are used for machining aircraft parts, engine blocks, etc.

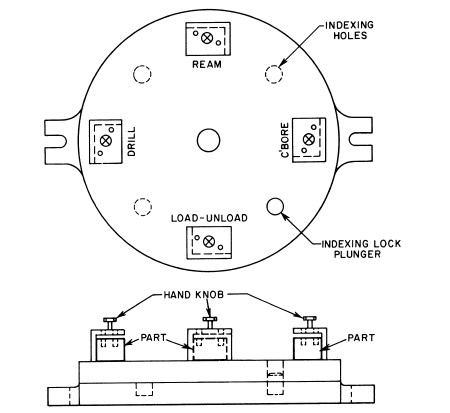

These are used for performing several operations simultaneously on a part. They have multiple stations that have different tools and workholding devices. While one part is drilled, another can be reamed, and a third counter-bored. The final station may be used for unloading the finished parts and loading fresh parts. They are used for mass production on multiple-spindle machines.

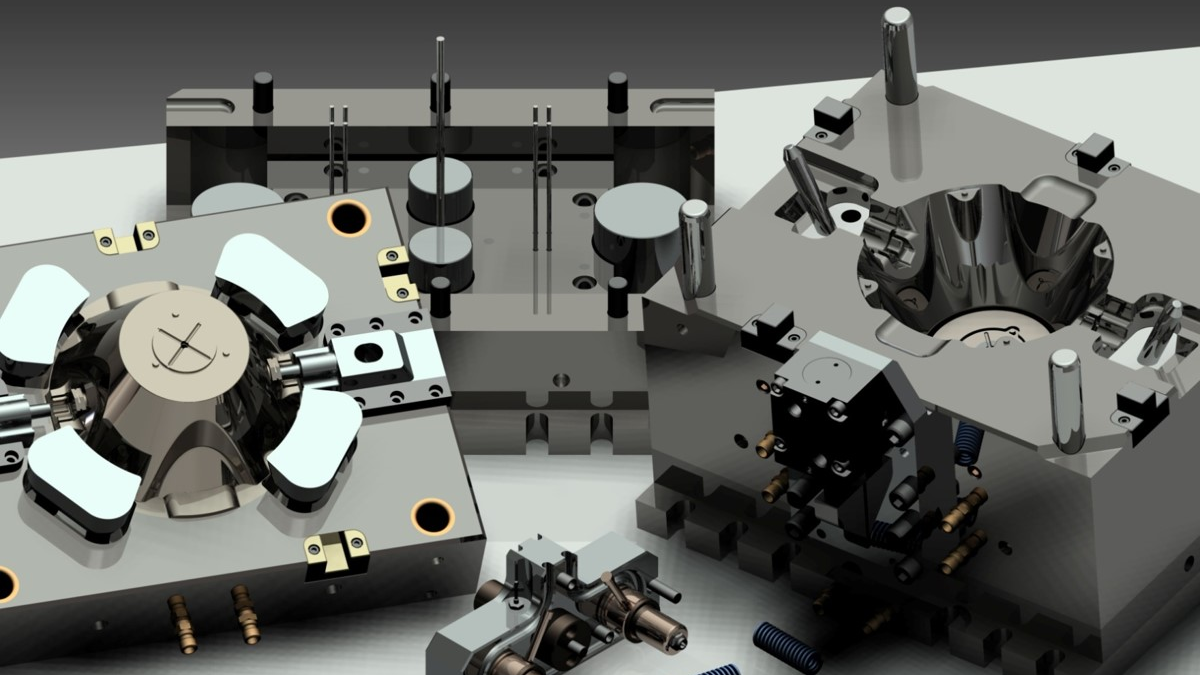

Fixtures are usually heavier than jigs, and need to withstand the cutting force and vibration. Fixtures are mainly used for milling, turning, grinding, and welding operations, while jigs are mainly used for drilling, reaming, tapping, and boring operations. There are different types and classifications of fixtures, such as:

These are fixtures that allow easy loading and unloading of the workpiece. They are used for machining simple and flat parts.

These are fixtures that enclose the workpiece completely and require special devices for loading and unloading. They are used for machining complex and irregular-shaped parts.

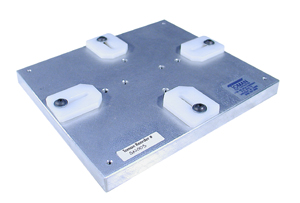

These are fixtures that can accommodate a range of workpieces with different sizes and shapes. They are used for machining parts that have common features or dimensions.

These are fixtures that consist of interchangeable components that can be assembled and disassembled according to the workpiece requirements. They are used for machining parts that have variable features or dimensions.

These are fixtures that have movable elements that can be adjusted to suit the workpiece size and shape. They are used for machining parts that have slight variations in size or shape.

These are fixtures that use hydraulic pressure to clamp the workpiece. They are used for machining parts that require high clamping force and accuracy.

These are fixtures that use air pressure to clamp the workpiece. They are used for machining parts that require low clamping force and speed.

These are fixtures that use magnetic force to clamp the workpiece. They are used for machining parts that are made of ferromagnetic materials.

• Increased precision: Both jigs and fixtures improve overall precision. Jigs help remove the potential inaccuracies caused by human error, whereas fixtures help securely hold raw material during machining to prevent any inaccuracies caused by the material movement or vibration.

• Increased productivity: Properly designed jigs and fixtures help reduce skill requirements for tasks that would otherwise require highly skilled personnel to achieve acceptable results. They also reduce the time and effort needed for loading, unloading, and positioning the workpieces, as well as for setting and adjusting the tools.

• Increased quality: Jigs and fixtures ensure that the workpieces are machined or assembled in a consistent and uniform manner, resulting in better quality and fewer defects. They also reduce the chances of damage or deformation of the workpieces during the process.

• Increased safety: Jigs and fixtures protect the operator and the machine from any hazards that may arise from the cutting or assembly process. They also prevent the workpieces from slipping or falling off the machine, which could cause injuries or accidents.

• Increased economy: Jigs and fixtures help reduce the cost of production by increasing the efficiency and effectiveness of the process. They also reduce the wastage of material and energy, and extend the life of the tools and the machine. They are usually designed to be durable and reusable, which saves money in the long run.

The difference between a jig and a fixture is that a jig is a device that guides the cutting tool to work at a predefined location on the workpiece, while a fixture is a device that holds and positions the workpiece but does not guide the tool. Jigs and fixtures are both used to improve the accuracy, quality, productivity, and safety of manufacturing processes, but they have different design, function, and application. Jigs are usually lighter and more complex than fixtures, and they are mainly used for drilling, reaming, tapping, and boring operations. Fixtures are usually heavier and simpler than jigs, and they are mainly used for milling, turning, grinding, and welding operations. There are different types and classifications of jigs and fixtures, such as open, closed, universal, modular, adjustable, hydraulic, pneumatic, magnetic, etc. They also have different elements and components, such as body, locating elements, clamping elements, and guiding elements. The design of jigs and fixtures depends on several principles and considerations, such as accuracy, rigidity, simplicity, economy, and safety.

Some additional, essential features of jigs and fixtures are:

• Jigs and fixtures are designed to suit the specific requirements of the workpiece and the operation. They are not interchangeable or universal, but rather customized for each application.

• Jigs and fixtures are usually made of materials that are strong, rigid, wear-resistant, and corrosion-resistant, such as steel, cast iron, brass, bronze, etc. They may also have some parts made of wood, plastic, rubber, or other materials to provide cushioning, insulation, or lubrication.

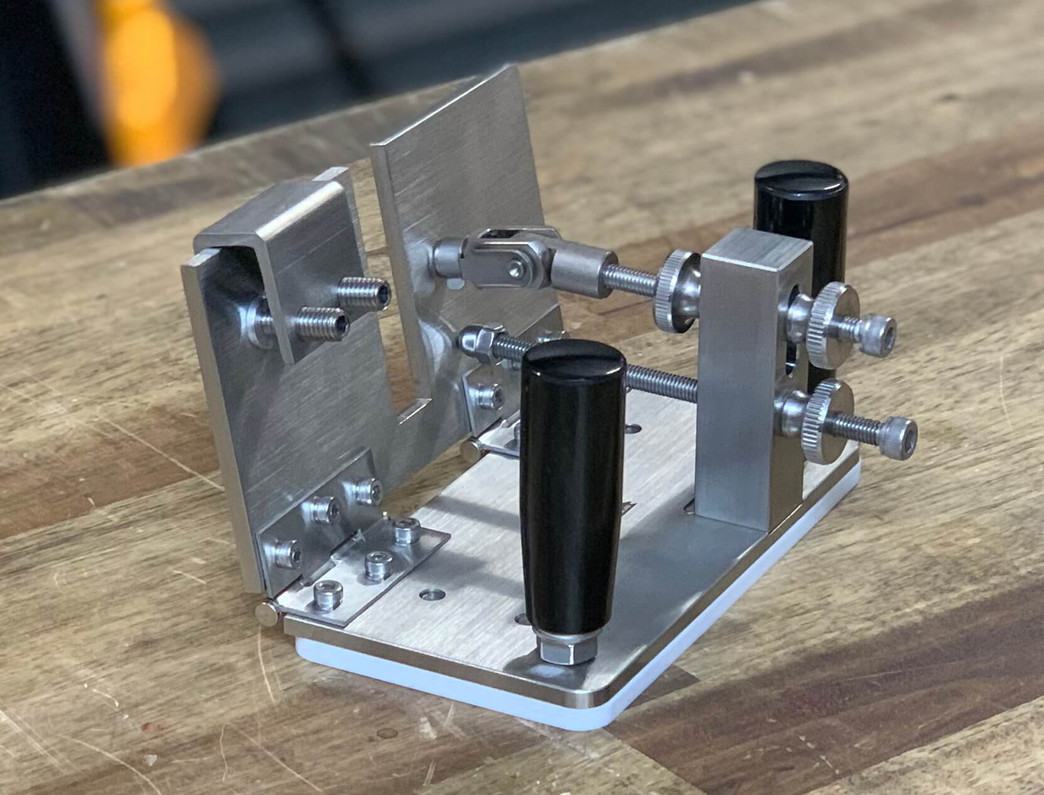

• Jigs and fixtures are often equipped with various devices and accessories to enhance their functionality and performance, such as springs, screws, nuts, bolts, pins, dowels, cams, levers, handles, knobs, etc. They may also have some special features, such as self-centering, self-releasing, self-adjusting, etc.

• Jigs and fixtures are subject to regular inspection and maintenance to ensure their accuracy, reliability, and durability. They may need to be cleaned, lubricated, calibrated, repaired, or replaced as necessary.

A jig is a device that guides the cutting tool to work at a predetermined position on the workpiece, while a fixture is a device that only holds and positions the workpiece without guiding the tool.

• A Jig has a sleeve or pin that aligns with the hole or feature to be machined on the workpiece and provides clamping and positioning functions, while a Fixture does not have a sleeve or pin and instead relies on the machine tool’s spindle or table for alignment and Only clamping function is provided.

•Jigs are generally lighter than fixtures, which require additional force to resist cutting forces and vibrations.

• Jig is mainly used for drilling, reaming, tapping and boring operations while Fixture is mainly used for milling, turning, grinding and welding operations.

Jig and Fixture come in various types and classifications, such as open, closed, universal, modular, adjustable, hydraulic, pneumatic, magnetic, etc. They also have different elements and components, such as bodies, positioning elements, clamping elements and guide elements. The design of jig and fixture depends on several principles and considerations such as accuracy, stiffness, simplicity, economy and safety.

Jig and fixture are important and beneficial tools in the manufacturing process, they can improve accuracy, quality, productivity and safety. They also automate and standardize production processes.

If you are looking for a professional jig and fixture manufacturer, I recommend you Richconn. Richconn is a company that provides precision CNC machining services. We have advanced equipment and technology, as well as experienced engineers and technicians. High quality jigs and fixtures, as well as other metal parts and components can be customized for you based on your needs and specifications.

CNC Axis TypesSeptember 28, 2022IntroductionCNC stands for “computer numerical control” and is a type of machine tool that uses encoded commands to operate various milling and cutting operations. The use of CNC machines has increa...view

CNC Axis TypesSeptember 28, 2022IntroductionCNC stands for “computer numerical control” and is a type of machine tool that uses encoded commands to operate various milling and cutting operations. The use of CNC machines has increa...view How to Reduce CNC CostsOctober 16, 2023In CNC machining, there are advances and improvements year after year. As a result, it is also becoming more complex. Consequently, it's also becoming more difficult to decide what to consider whe...view

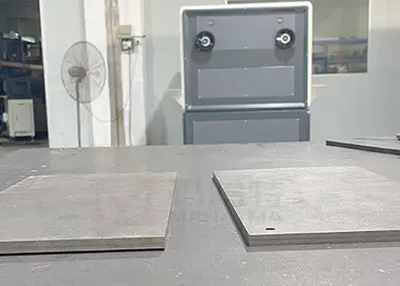

How to Reduce CNC CostsOctober 16, 2023In CNC machining, there are advances and improvements year after year. As a result, it is also becoming more complex. Consequently, it's also becoming more difficult to decide what to consider whe...view Steel Plate Flatness Tolerance: The Choice When You Have Flatness Tolerance for Steel PlatesAugust 4, 2023With the continuous improvement of manufacturing quality requirements, steel plates, as an important basic material and mechanical component, their flatness directly affects the precision of subsequen...view

Steel Plate Flatness Tolerance: The Choice When You Have Flatness Tolerance for Steel PlatesAugust 4, 2023With the continuous improvement of manufacturing quality requirements, steel plates, as an important basic material and mechanical component, their flatness directly affects the precision of subsequen...view Fundamentals and Techniques of Engineering DrawingsDecember 1, 2023Engineering drawings are a graphical language used to express engineering design ideas and details, and they are an important tool for engineers for design, manufacturing and maintenance. Engineering drawings follow a number of international or national standards and specifications to ensure the accuracy, consistency and readability of engineering drawings.view

Fundamentals and Techniques of Engineering DrawingsDecember 1, 2023Engineering drawings are a graphical language used to express engineering design ideas and details, and they are an important tool for engineers for design, manufacturing and maintenance. Engineering drawings follow a number of international or national standards and specifications to ensure the accuracy, consistency and readability of engineering drawings.view Precision Components: Unveiling Excellence in CNC ManufacturingNovember 17, 2023In the realm of precision engineering, where intricacy meets innovation, the quest for superior precision components drives industries forward. At Richconn, we don't just craft components; we sculpt reliability and precision. Prepare to delve deep into the world of precision components with us, discovering the nuances, intricacies, and pathways to excellence.view

Precision Components: Unveiling Excellence in CNC ManufacturingNovember 17, 2023In the realm of precision engineering, where intricacy meets innovation, the quest for superior precision components drives industries forward. At Richconn, we don't just craft components; we sculpt reliability and precision. Prepare to delve deep into the world of precision components with us, discovering the nuances, intricacies, and pathways to excellence.view American Scientific Research Has Found A Fast And Effective Processing Method Of Low-Temperature Titanium AlloyMay 30, 2022Titanium is widely used in the aerospace industry because of its high strength and low density. However, compared with steel, aluminum, and other metals, its hot processing cost is high and it is at a...view

American Scientific Research Has Found A Fast And Effective Processing Method Of Low-Temperature Titanium AlloyMay 30, 2022Titanium is widely used in the aerospace industry because of its high strength and low density. However, compared with steel, aluminum, and other metals, its hot processing cost is high and it is at a...view