Electrophoretic coatings are widely used on steel products to provide corrosion resistance and protection.

Richconn electrophoresis coating companies specializing in all kinds of metal surface electrophoresis coating, can electrophoresis color, black, roll spraying a variety of colors, etc., the factory relies on 16 years of experience in electrophoresis technology, a wide range of materials (copper, aluminum, iron, stainless steel, aluminum alloys, zinc alloys, and other materials) surface finishing research.

Electrophoretic coating (also known as e-coat, electrocoating, electrophoretic coated) is a coating method in which parts and corresponding electrodes are put into water-soluble paints, and after connecting to the power supply, relying on the physicochemical effect produced by the electric field, the resin and pigment filler in the paint are precipitated and deposited uniformly on the surface with the coated object as the electrode to form an insoluble film of paint. A coating method, can play a corrosion prevention, improve the appearance, improve the abrasion resistance, adhesion rate, insulation effect, contact us for a quote!

Electrophoretic coatings are widely used on steel products to provide corrosion resistance and protection.

Aluminum products, such as automotive parts, building components, and household items, are also often coated with electrophoretic coatings.

Electrophoretic coatings can be used on magnesium alloys to increase their corrosion resistance.

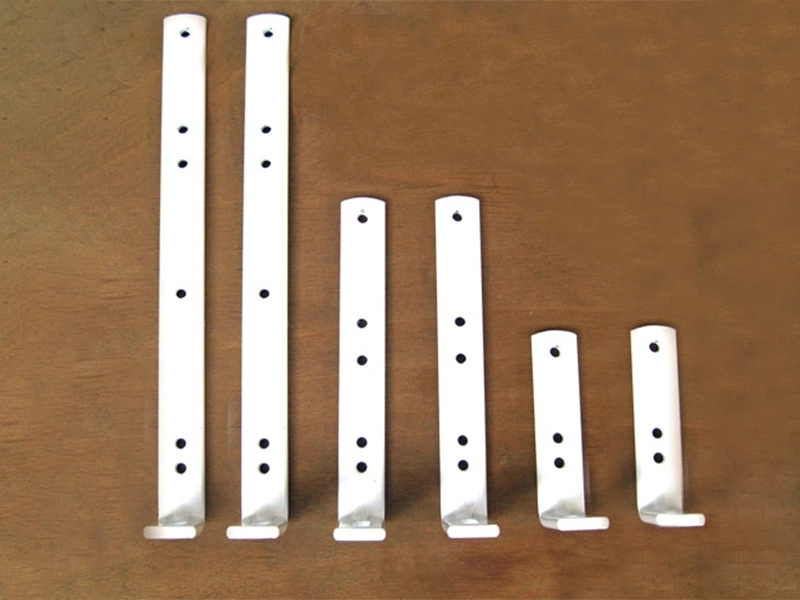

Zinc plating is often used to prevent corrosion, while electrophoretic coatings can provide additional protection and decorative effects.

Electrophoretic coatings can be used to coat copper products to provide protection and improve appearance.

Although stainless steel itself has good corrosion resistance, electrophoretic coatings can enhance its durability and provide different colors and decorative effects.

Various metal alloys, such as nickel alloys and cobalt alloys, can also be coated with electrophoretic coatings to increase their properties and appearance.

Richconn Limited is a company specializing in all kinds of metal surface electrophoresis coating (mainly black) for 16 years, and can electrophoresis glossy and matte. The raw materials used are imported to ensure that the surface coating of customer products can meet the standard requirements of export products. Can be applied in hardware die-casting parts, stamping parts, (copper, aluminum, iron, stainless steel, aluminum alloy, zinc alloy) and a series of electronic hardware products.

Many years of experience in metal electrophoresis R & D and production, the world's long-term designated partners of various enterprises, with domestic excellent production technology, product variety and comprehensive specifications.

We can customize automated production line and precision production equipment for customers. We can adjust the design and production according to different needs.

Through continuous efforts, trusted by the majority of users. Complete specifications, cost-effective! Good product quality, environmental protection, long service life.

The service team provides 24-hour professional service for customers, and the technical team has been engaged in metal electrophoresis industry for 16 years.

Electric coating is widely used in many industries, providing you with one-stop electrophoresis solutions.

We can offer electrophoretic coating treatments for a wide range of metal materials, whether steel, aluminum, stainless steel, magnesium, zinc, copper, or a variety of metal alloys, all of which can benefit from this method for a corrosion-resistant, decorative, and protective coating.

EN

EN

ru

ru