Rubber, or rubber in Chinese (xiàng jiāo), is an extraordinary material with a rich history and diverse applications. In this in-depth analysis, we will embark on a journey to understand rubber, from its raw materials to its wide range of applications. Rubber: Materials, Processing and Applications Full Analysis is a topic covering innovation, science and industry, and we will reveal its mysteries for you here.

The story of rubber began in the center of South America, where indigenous peoples used rubber tree emulsion for waterproofing and made balls for Mesoamerican ball games. This versatile material quickly caught the attention of European explorers, and the rubber trade began.

Natural rubber is mainly harvested from the emulsion of rubber trees. This milky white substance contains a polymer called polyisoprene, which makes it highly elastic. The processing of natural rubber includes solidification, rolling, and drying to produce sheets or shapes.

On the other hand, synthetic rubber is prepared through the polymerization of various petrochemical products. This innovation expands the possibilities of rubber-based products, as synthetic rubber can be customized for specific applications.

Rubber has good elasticity and can still return to its original shape after being greatly deformed. This is determined by the special molecular structure of benzene-propylene repeat units in rubber molecules.

Rubber is a good electrical insulator with high resistivity, which can isolate and protect current. This makes it widely used in electrical cables, electrical rubber products, etc.

Rubber can fit tightly to different surfaces and has a good sealing effect. This is due to its flexibility and elastic deformation ability. It is commonly used as a sealing material for pipes, doors and windows, etc.

Rubber has certain corrosion resistance to chemical media such as acid, alkali, and brine, making it suitable for use in corrosive environments. However, it is not resistant to petroleum cracking products.

After vulcanization and the addition of fillers, rubber can obtain good mechanical strength and wear resistance, making it suitable for use in wear-bearing parts such as tires.

Rubber has good impact absorption and cushioning properties and can be used to make shock absorption and isolation products.

Rubber is susceptible to degradation by ozone and ultraviolet radiation, and antioxidants need to be added when used.

The use temperature range of rubber is limited, and long-term high temperature will degrade and age rubber.

In summary, rubber combines various excellent properties such as elasticity, insulation, sealing, corrosion resistance, and wear resistance, and is an extremely important industrial material. However, it also has the disadvantage of poor heat resistance and ozone resistance

Rubber itself does not have the function of preventing nulear radiation, but it can be combined with other materials to improve the overall radiation protection effect.

1. Mix with lead:

Styrene in rubber can be combined with lead to form lead-containing rubber composites. Lead can absorb and block gamma rays and X-rays, thereby improving protection against nuclear radiation. However, lead is heavy and expensive.

2. Mix with barium cobaltate:

Barium cobaltate also has strong gamma and X-ray absorption capabilities. Adding an appropriate amount of barium cobaltate can improve the radiation resistance of rubber.

3. Mixed with boron:

Boron can capture neutron radiation, and adding boron elements such as boric acid can enhance the neutron protection effect of rubber materials.

4. Thickening:

Increasing the thickness of rubber products can improve the weakening and absorption of various nuclear radiation, but it will increase weight.

5. Multi-layer coating:

Coating the rubber layer with a lead layer or other radiation-proof layer can play a synergistic protective role of each layer of material.

6. Structural design:

The honeycomb porous or box structure is used to increase the path of radiation through the rubber layer and improve the overall radiation protection effect.

Therefore, rubber itself has limited radiation protection effect, but when combined with other radiation protection materials, better nuclear radiation protection products can be made through structural design. This requires selecting different protection schemes according to actual needs.

One of the most important advances in rubber processing is vulcanization. This process was discovered by Charles Goodyear and involves adding sulfur to rubber and heating it. The result is a more durable and temperature-resistant material.

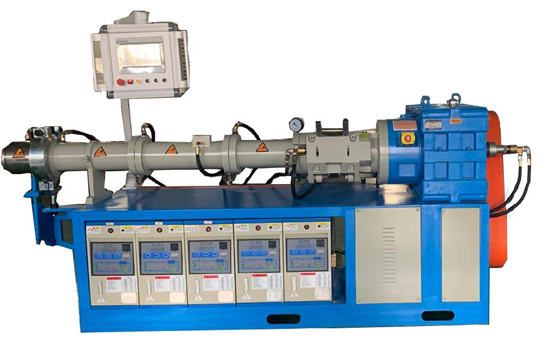

Rubber can be molded into various shapes through extrusion and molding processes. Extrusion creates a long and uniform shape by passing rubber through a mold, while molding uses a specific mold to shape rubber into the desired item.

Rolling

Calendering is a technique used to create rubber sheets with precise thickness and texture. It is usually used to produce conveyor belts, gaskets, and flooring materials.

Compression molding

Molding methods can also be used to manufacture rubber products with complex shapes (such as leather bowls and sealing rings), and the rubber material is placed in the mold for hot molding with the help of molded yin and yang molds.

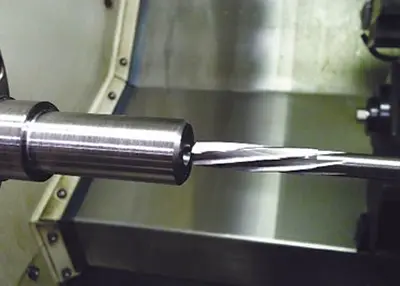

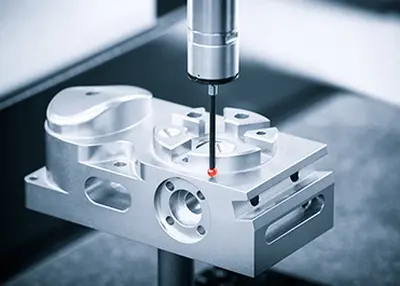

Numerical control machining

1. Processing equipment

Rubber CNC machining usually requires the use of numerical control engraving machines or laser cutting machines. Compared with ordinary mechanical processing, they can perform more delicate and complex cutting and engraving.

2. Control mode

Rubber CNC machining can be carried out according to pre-edited NC code, or combined with CAD design for numerical control interactive processing.

3. Processing technology

Rubber CNC machining includes cutting, engraving, milling, etc. When cutting, it is necessary to control the cutting speed to prevent rubber from burning. When engraving, pay attention to the type of tool selection.

4. Workpiece fixing

Due to the softness and deformation of rubber, reliable positioning and fixation with vacuum suction cups or ixtures is required during CNC machining.

5. Cooling lubrication

Cutting fluid is required for cooling and lubrication during processing to prevent rubber from sticking to the tool. It can also be processed directly in caramel or soapy water.

6. Processing accuracy

Rubber CNC machining can achieve high precision of 0.1mm. However, due to the elastic deformation of the rubber, the positional tolerance needs to be confirmed in advance.

7. Post-processing

The processed rubber surface is rough and needs to be polished or sprayed. It can also be directly vulcanized.

Rubber is the cornerstone of the automotive industry. It is used in tires, hoses, seals, and gaskets to ensure safety performance when driving on the road.

In the healthcare sector, rubber is essential for seals and gloves in manufacturing equipment, pipes, and various medical devices.

The versatility of rubber extends to the construction sector, where it is used for seals, gaskets, and vibration-absorbing materials.

From footwear to household items, rubber plays a key role in our daily lives. Its elasticity and durability make it an ideal choice for countless consumer goods.

Rubber is used in the aerospace industry for seals, gaskets, and vibration isolation critical components, contributing to flight safety.

In recent years, the rubber industry has received attention due to its environmental impact. Concerns have been raised about logging and waste disposal for rubber tree plantations. However, efforts are currently underway to develop sustainable practices and environmentally friendly alternatives.

A: The history of rubber can be traced back to ancient Mesoamerica, where indigenous peoples used emulsion for various purposes. European explorers introduced it to the world.

Answer: Natural rubber is processed by solidifying, rolling, and drying the emulsion of rubber trees.

Answer: In the automotive industry, rubber is used in tires, hoses, seals, and gaskets.

A: Synthetic rubber has advantages such as customization to specific needs, and is generally considered as good or even better than natural rubber in some applications.

Answer: Vulcanization enhances the performance of rubber by making it more durable, heat-resistant, and less susceptible to environmental factors.

Answer: The rubber industry is actively working towards sustainable practices, including environmentally friendly alternatives and responsible plantation management.

Rubber: Materials, Processing, and Applications is a fascinating topic that connects the gaps between history, science, and industry. From its humble origins in South America to its key role in modern society, rubber is constantly evolving and adapting to our changing needs. The rubber industry is committed to ensuring that this outstanding material continues to be an indispensable part of our lives, actively embracing sustainable practices.

Machining on a Dime: Creating High-Quality Products with Cheap CNC MaterialsDecember 4, 2023In today's fast-paced world, businesses are constantly seeking ways to reduce costs without compromising on quality. This is particularly true for manufacturers who heavily rely on CNC machining t...view

Machining on a Dime: Creating High-Quality Products with Cheap CNC MaterialsDecember 4, 2023In today's fast-paced world, businesses are constantly seeking ways to reduce costs without compromising on quality. This is particularly true for manufacturers who heavily rely on CNC machining t...view What Is Reaming & Reamer And Their DifferencesSeptember 26, 2023Reaming is an important process in CNC machining services, and its main purpose is to join parts or components so that they can rotate or oscillate relative to each other and move at a specific angle or direction.view

What Is Reaming & Reamer And Their DifferencesSeptember 26, 2023Reaming is an important process in CNC machining services, and its main purpose is to join parts or components so that they can rotate or oscillate relative to each other and move at a specific angle or direction.view The Comprehensive Guide to Sheet Metal Thickness Gauge 2024January 22, 2024What is metal gauge thickness? This article explains everything you need to know about the use of sheet metal gauge thickness.view

The Comprehensive Guide to Sheet Metal Thickness Gauge 2024January 22, 2024What is metal gauge thickness? This article explains everything you need to know about the use of sheet metal gauge thickness.view Basic Parts of CNC Lathe and Their MaintenanceOctober 20, 2023CNC lathes and steering centers are highly accurate and efficient automatic machine tools. The machine is equipped with a multi-station turret or power turret for a wide range of machining capabilities. It can handle linear cylinders, tilting cylinders, arcs and a variety of complex workpieces such as threads, grooves, worms, etc.view

Basic Parts of CNC Lathe and Their MaintenanceOctober 20, 2023CNC lathes and steering centers are highly accurate and efficient automatic machine tools. The machine is equipped with a multi-station turret or power turret for a wide range of machining capabilities. It can handle linear cylinders, tilting cylinders, arcs and a variety of complex workpieces such as threads, grooves, worms, etc.view Rivets: 25 Types Of Introduction And User GuideSeptember 26, 2023Rivets are parts that join multiple components and structures together to form a complete body. These parts can be manipulated with some specialized tools. One of the panaceas of manufacturing is rivets. Depending on their design requirements and performance, different types of rivets can be used.view

Rivets: 25 Types Of Introduction And User GuideSeptember 26, 2023Rivets are parts that join multiple components and structures together to form a complete body. These parts can be manipulated with some specialized tools. One of the panaceas of manufacturing is rivets. Depending on their design requirements and performance, different types of rivets can be used.view Material Comparison: Difference between High Speed Steel and Tungsten SteelOctober 31, 2023Materials play a vital role in modern industry, and in the field of precision manufacturing, both high-speed steel and tungsten steel are highly regarded materials. They have an important position in the field of tool, mold and mechanical parts manufacturing, etc. However, there are obvious differences between them in terms of characteristics, features, application areas, etc. In this article, we will introduce and compare them. This article will be introduced and compared.view

Material Comparison: Difference between High Speed Steel and Tungsten SteelOctober 31, 2023Materials play a vital role in modern industry, and in the field of precision manufacturing, both high-speed steel and tungsten steel are highly regarded materials. They have an important position in the field of tool, mold and mechanical parts manufacturing, etc. However, there are obvious differences between them in terms of characteristics, features, application areas, etc. In this article, we will introduce and compare them. This article will be introduced and compared.view

EN

EN

ru

ru