In the past, everything was simple: round parts were turned on lathes, while non-round parts were machined on mills. With the advent of CNC machining centers that effortlessly insert round part features, the dividing line between the two machining processes became blurred.

The situation became even more confusing when it became possible to run CNC lathes with live tools. Machining operations that were once the exclusive domain of the milling department could now be performed entirely on the lathe. Deciding which machine was best suited for a particular part became a lot more complicated.

For some parts, turning is an obvious choice. Consider, for example, the piston for a gate valve or a hydraulic fitting. Their cylindrical symmetry, coupled with complex external geometry and sophisticated internal features, make these components at home in the turning shop.

Conversely, the rectangular valve stem associated with these turned parts, with its large milled surfaces, detailed pockets and intersecting bores, will never be turned on a lathe, no matter how well the machine can be operated with live tooling.

These are some of the reasons why our CNC milling service chose to turn. By adding CNC turning centers with live tools (end mills) to our already extensive 3-axis milling service, we are able to produce a better surface finish on cylindrical features. And that, usually more favorable final prices. Moreover, the turning process makes more efficient the production of those parts where our milling process reaches its limits. And if small series production is the goal, turned parts are a good choice.

Do you have a concept design for a new optimal camera lens housing? Or a revolutionary drive shaft for a lawn mower with milled flats and tapped cross holes? Chances are we can provide a turned prototype for that geometry.

Turned parts like this offer several advantages over milled parts. As indicated earlier, large length-to-diameter ratios for pistons and shafts often give machining engineers a bellyache. Turning candlesticks for your aunt's 60th birthday, on the other hand, is a breeze on the lathe.

If you're unsure about which parts are worth turning, consider a few household items. A pint glass, for example, with its smooth, regular shape, whose length is quite a bit greater than its outside diameter, is a simple exercise on the lathe. Not so at the milling center. A coffee cup, on the other hand, with its protruding handle and convenient finger hole, is impossible to turn.

Bar stock made of metal is clamped tightly into a high-speed CNC lathe before turning and milling begins.

The 1.5-pound dumbbells that like to collect dust in the closet can be made quite easily on a lathe. The wide, relatively large recess, for gripping the bar, can be turned with a simple hollowing step - on a mill, the feature would be extremely difficult to make.

A small saucer could be made using either process. Insertion of the concentric edges and curved surfaces is equally possible on a mill and a lathe; all that is needed is an accurate G-code and a suitable cutting device. Nevertheless, it would undoubtedly be faster and far more material efficient to turn the saucer.

What about hose nozzles for sprinklers? The V-shaped grooves would have to be produced with a special milling machine in a milling center, whereas a standard turning tool would suffice on a lathe. The same is true for a replacement wheel for a grill, although the small mag-wheel-like recesses on the surface would be difficult or impossible to mill with lathe machines.

Cans and salt shakers, water bottles and flower pots - these shapes are made for lathes. Milk cartons and picture frames, on the other hand? Not particularly. Richconn offers a variety of CNC machining materials, including aluminum, brass, low carbon steel, stainless steel, steel alloy and titanium.

In terms of size, we will produce parts with a maximum diameter of 73 mm (sometimes up to 74 mm, depending on geometry) by a length of 228 mm, as well as a minimum diameter of 4 mm by 1.5 mm in length. Sharp tapered points are acceptable as long as the angle is greater than 30 degrees. No compromise on ballpoint pen prototypes or drinking straw models.

As mentioned earlier, our lathes are capable of milling. Drilling a side hole or milling a flat surface is within their capabilities as long as the feature is parallel or perpendicular to the long axis of the part. Unfortunately, however, chamfered holes are not possible. All milled slots should be wider than 1.2mm, but since all of our lathes are equipped with a Y-axis, we can mill slots or holes off-center (within reason).

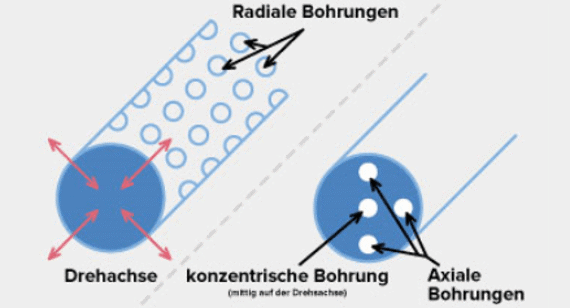

Do you want your company name engraved on the parts? Recessed text is best done with the milling process; raised text is the best option with the lathe. We can mill just about any lettering as long as the line thickness and character spacing is at least 0.5mm. Small bores don't scare us, nor do threads. In fact, we produce radial bores up to 2 mm and axial bores up to 1 mm. Likewise, we support a range of UNC, UNF and metric internal and external threads.

Richconn is capable of machining radial, on axis, and axial bores

If you have used our milling services before, you may have noticed that turned surfaces are smoother and rounder than their milled counterparts. Milled features may have visible tool marks; however, we can polishing these surfaces to give them a matte finish and remove any small burrs that remain after the milling process.

As with all milled parts, the machining process begins with entering the CAD model into our quoting service. Our engineers determine which machining method is best for the material in question (milling or turning). However, you can sometimes override this decision when configuring the quote. Each process has different options for producing desired features and threads. The two processes also differ in price. When configuring the quote, after weighing these factors, select the machining process that most meets your needs. If a part is not eligible for the turning process with a particular material, that option will not be available in the quote for that material.

We have found over the years that making round parts from square or rectangular bar stock can leave a few things to be desired. Milling away the sharp edges to produce the round part takes more time than turning from bar stock. It also produces more material waste. Turning such parts in a suitable machine is certainly a win-win situation for everyone. To learn more about Richconn's CNC turning service, review our procedures and guidelines webpage or upload your part now to see if it qualifies for the process.

Top 12 CNC Machining Manufacturers in the USAJune 8, 2024Looking for reliable CNC machining parts manufacturers in the USA? Check out our list of the top 12 companies, each with its own unique advantages and processing capacities. Find the perfect partner for your business today!view

Top 12 CNC Machining Manufacturers in the USAJune 8, 2024Looking for reliable CNC machining parts manufacturers in the USA? Check out our list of the top 12 companies, each with its own unique advantages and processing capacities. Find the perfect partner for your business today!view Carbon Steel: The Ultimate Guide - Types, Properties & PriceSeptember 8, 2023Carbon steel is one of the most common types of steel, as it is cheap, abundant, and versatile. Carbon steel found in countless products and structures, plays an indispensable role in various industri...view

Carbon Steel: The Ultimate Guide - Types, Properties & PriceSeptember 8, 2023Carbon steel is one of the most common types of steel, as it is cheap, abundant, and versatile. Carbon steel found in countless products and structures, plays an indispensable role in various industri...view What Products Can Be Customized with a Five Axis CNC Machining Center?August 14, 2023A five-axis machining center is a highly technological, high-precision machine tool specialized in processing complex surfaces, and has a crucial influence on industries such as national aerospace, mi...view

What Products Can Be Customized with a Five Axis CNC Machining Center?August 14, 2023A five-axis machining center is a highly technological, high-precision machine tool specialized in processing complex surfaces, and has a crucial influence on industries such as national aerospace, mi...view The Glass Transition Temperature of PolymersOctober 17, 2023When designing parts for plastic injection molding, there is an important but often overlooked material consideration. It involves the glass transition temperature, or Tg. We'll get into the underlying science later, but for now, keep in mind that there is a temperature at which amorphous materials transition from a glassy/rigid state to a leathery/rubbery state.view

The Glass Transition Temperature of PolymersOctober 17, 2023When designing parts for plastic injection molding, there is an important but often overlooked material consideration. It involves the glass transition temperature, or Tg. We'll get into the underlying science later, but for now, keep in mind that there is a temperature at which amorphous materials transition from a glassy/rigid state to a leathery/rubbery state.view The Functional Advantages of Custom PVD Coating in Automotive DesignJanuary 5, 2024When it comes to automotive design, every detail matters. From the sleek lines of the exterior to the carefully crafted interior, each element plays a crucial role in creating a unique and memorable d...view

The Functional Advantages of Custom PVD Coating in Automotive DesignJanuary 5, 2024When it comes to automotive design, every detail matters. From the sleek lines of the exterior to the carefully crafted interior, each element plays a crucial role in creating a unique and memorable d...view Machined Bearings Basics and Working PrinciplesNovember 9, 2023Welcome to the world of Machined Bearings, where precision engineering meets mechanical efficiency. If you're here, you're probably as curious as I was when I first delved into this field. You're in for a treat because we've crafted a comprehensive guide to take you on a journey through Machined Bearings, from the basics to advanced applications.view

Machined Bearings Basics and Working PrinciplesNovember 9, 2023Welcome to the world of Machined Bearings, where precision engineering meets mechanical efficiency. If you're here, you're probably as curious as I was when I first delved into this field. You're in for a treat because we've crafted a comprehensive guide to take you on a journey through Machined Bearings, from the basics to advanced applications.view

EN

EN

ru

ru