You may be wondering why custom CNC motorcycle parts. So let's dive into why this is a new trend in the motorcycle manufacturing industry.

Two-wheeled vehicles motorcycles are more prone to accidents than four-wheeled vehicles. In case of an accident, the motorcycle parts get damaged and these damaged parts need to be replaced if you want to continue enjoying your motorcycle.

Often, it is difficult to find the ideal replacement or at least something you like in the market. This is where machined motorcycle parts prove their importance. In addition, you get to decide exactly how the parts will look, down to the details.

Sometimes, motorcycle riders will choose to upgrade their motorcycle parts or give them a sleeker look. Again, CNC machining is a much more viable option. You can design how and what type of upgrade you want.

In the past, CNC machined parts seemed expensive. However, this is no longer the case as they are now easily available at affordable prices. In addition, no matter what kind of upgrade you are seeking, it will only take a few days to deliver after placing the order.Richconn was founded in 2008 as a China precision machine works, we can complete your custom machining of motorcycle parts for you, supporting a wide range of CNC material customization, contact us for a quick quote.

CNC machines perform operations autonomously without human intervention, which means that the possibility of human error is reduced. Additionally, CNC machining allows for the machining of motorcycle parts that are virtually free of defects or flaws.

In addition, motorcycle manufacturers can always continue to produce and customize motorcycle parts with 100% accuracy. The premise is that companies use the same codes and materials. Thus they can produce unique motorcycle parts.

CNC machines work fast and do not have any negative impact on the final production process. What's more, these machines can run for long periods of time, thus allowing for the machining of motorcycle parts in a short period of time.

Lesser production time ensures quick detection of errors for proper correction and improvement. Overall, manufacturers can quickly move on to the next stage: post-processing operations.

Virtually all metal and plastic parts for motorcycles can be machined with CNC machining. Below, we will discuss some machined motorcycle parts.

Unlike automobiles, motorcycle wheels tend to be more noticeable. Therefore, properly customizing these wheels will improve the aesthetics of your motorcycle. After all, aesthetics are more than just something that easily catches the eye.

When it comes to customizing wheels, discs happen to be the target. Most of them are made of aluminum. Aluminum is known for its excellent machining properties. Precision CNC milling operations are used to customize the wheels.

Tires are another area that requires customization. Once you get a customized wheel disc, it makes sense to choose tires with great designs.

The engine of a vehicle (motorcycle) is the most critical component. Some refer to it as the heart of the vehicle. However, camshafts, cylinder heads and pistons are often complex and require high precision design. Precision CNC turning is the technology of choice for designing motorcycle engine parts.

The cylinder head, usually made of aluminum, controls fuel combustion by regulating the fuel-air mixture. In addition, the mixture passes through the combustion chamber at a specific angle. Sharper angles result in more fuel combustion, which increases the propulsion of the motorcycle. We won't let you get tired of these mechanisms. The cylinder head is an important part of the motorcycle. The valves in the cylinder head that help regulate fuel intake are CNC machined products.

Camshafts control the engine cycle. They are made from CNC turned parts with different angles. The shafts in the engine rotate, causing the cams to open the fuel intake and exhaust valves. However, these shafts can be modified to allow for increased cam opening times. As a result, more fuel is burned to produce more electricity.

The above modifications ensure an increased workload on the piston. As a result, CNC customized pistons also become vital to withstand the pressures and temperatures caused by other engine part modifications.

Lights are another complex part of customization. However, you need to use high-quality products because apart from being aesthetically pleasing, these lights are vital for the safety of riders and other road users, especially in the dark. Motorcycle lights consist of a light source (mainly a bulb), a lens and a cover. Notably, the lens and cover are the parts we focus on customizing.

The lenses are metal - usually made of aluminum alloy. A milling operation with a perfect finish will give the lens a shiny, almost mirror-like appearance. The cover, however, is made of tough plastic, which can also be machined to present an exquisite shape.

Above is the science of motorcycle CNC machining parts, if you have any questions and CNC machining service needs, you can contact us!

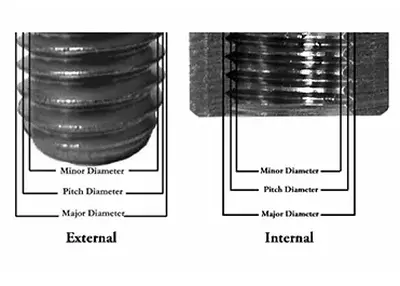

UNF Threads vs UNC Threads and What Are UNF Threads and UNC ThreadsNovember 17, 2023In the intricate world of CNC machining, understanding the nuances of UNF Threads and UNC Threads is paramount. These threading standards, Unified National Fine (UNF) and Unified National Coarse (UNC), serve as the bedrock of precision in mechanical engineering. Let's delve into the specifics, exploring their applications, differences, and the critical role they play in the realm of precision machining.view

UNF Threads vs UNC Threads and What Are UNF Threads and UNC ThreadsNovember 17, 2023In the intricate world of CNC machining, understanding the nuances of UNF Threads and UNC Threads is paramount. These threading standards, Unified National Fine (UNF) and Unified National Coarse (UNC), serve as the bedrock of precision in mechanical engineering. Let's delve into the specifics, exploring their applications, differences, and the critical role they play in the realm of precision machining.view A Basic Introduction to CNC LathesJune 11, 2024If you're eager to delve into the captivating realm of CNC lathes, this article is your gateway. Whether you're interested in their specific functionalities, wide-ranging applications, or significant roles in the manufacturing industry, this is the perfect read to quench your curiosity.view

A Basic Introduction to CNC LathesJune 11, 2024If you're eager to delve into the captivating realm of CNC lathes, this article is your gateway. Whether you're interested in their specific functionalities, wide-ranging applications, or significant roles in the manufacturing industry, this is the perfect read to quench your curiosity.view Exploring Chameleon PVD Coating in DesignJanuary 5, 2024The world of design is constantly evolving, with new techniques and materials pushing boundaries and inspiring creativity. One such innovation that has revolutionized the design industry is Chameleon ...view

Exploring Chameleon PVD Coating in DesignJanuary 5, 2024The world of design is constantly evolving, with new techniques and materials pushing boundaries and inspiring creativity. One such innovation that has revolutionized the design industry is Chameleon ...view Types of Screws: A Comprehensive GuideSeptember 28, 2023Are you tired of struggling with mismatched screws or wondering which type is best for your project? Look no further! In this extensive guide, I will take you on a journey through the fascinating world of screws, from the basics to specialized types.view

Types of Screws: A Comprehensive GuideSeptember 28, 2023Are you tired of struggling with mismatched screws or wondering which type is best for your project? Look no further! In this extensive guide, I will take you on a journey through the fascinating world of screws, from the basics to specialized types.view How many types of cast iron are there? How are the grades represented? The various uses of cast iron?October 31, 2023Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains mangan...view

How many types of cast iron are there? How are the grades represented? The various uses of cast iron?October 31, 2023Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains mangan...view Custom Machined Metal Parts: Precision at Your FingertipsNovember 9, 2023Do you crave perfection in your machinery? Are you seeking the ideal metal components for your projects? You've come to the right place! Welcome to Richconn, your reliable partner for custom machined metal parts. In this comprehensive guide, we'll explore the world of precision engineering, from understanding the basics to choosing the right materials, processes, and designs.view

Custom Machined Metal Parts: Precision at Your FingertipsNovember 9, 2023Do you crave perfection in your machinery? Are you seeking the ideal metal components for your projects? You've come to the right place! Welcome to Richconn, your reliable partner for custom machined metal parts. In this comprehensive guide, we'll explore the world of precision engineering, from understanding the basics to choosing the right materials, processes, and designs.view

EN

EN

ru

ru