It is generally used in the machining of small-diameter threads, but its precision is relatively poor. Therefore, if high precision is required, tapping should be avoided. To ensure the application of tapping, appropriate drill hole should be selected with corresponding drill diameter, and the diameter tolerance of the bottom hole of the thread can be coordinated with each other, which can effectively reduce the workload of tapping in subsequent work and reduce the probability of damage to the tap in actual machining. The damage of the tap is mainly due to the difficulty in forming a coordination relationship with the material being machined when the tap is in contact with it, which can easily cause damage to the tap or reduce its durability. At present, the most widely used taps in actual production are through-hole taps and blind-hole taps. Reasonable selection should be made according to the requirements of thread processing in production.

The application of extraction processing method is relatively rare in actual production and is generally used as an emergency measure in the absence of thread milling tools and taps. It is usually applied in the situation where large thread holes need to be made in the box parts, and boring and tapping processing is needed with the help of thread turning tool and boring rod. In the process of OEM precision CNC machining, the rotation speed of the spindle should be paid attention to, and effective control should be carried out for the delay and other phenomena that are prone to occur before the rotation of the spindle, so as to avoid affecting the threading processing due to improper rotation speed. In the processing of multi-rod, the position between the rod should be ensured to keep the corresponding position consistent with the slot to avoid disorderly processing and affect the final processing effect of the finished product. In the processing method, one-shot extraction should be avoided as much as possible, and multi-cutting operation should be processed to better improve the effect of threading.

In order to better improve the level of CNC machining technology, attention should not only be paid to the upgrading of mechanical CNC software and hardware systems and the corresponding personnel competence, but also to the research of CNC technology and machining methods of the machine.

The automation and intelligence of CNC machine tools can reduce the influence of machining accuracy caused by artificial operation, but the machining system error of the machine itself cannot be avoided. Different machining processes can be adopted according to the quality standards, component composition, performance characteristics, appearance shape and actual situation of different parts in production to minimize the generation of machining errors from the initial stage of part machining and match the machining process with part machining.

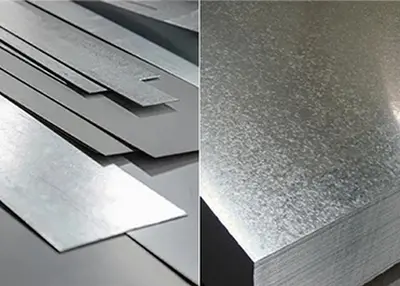

Unveiling the Power of Galvanized Materials: Your Ultimate GuideSeptember 28, 2023Have you ever wondered about the remarkable process that transforms ordinary steel into a corrosion-resistant wonder material? Look no further, as we embark on an enlightening journey to understand the world of galvanization.view

Unveiling the Power of Galvanized Materials: Your Ultimate GuideSeptember 28, 2023Have you ever wondered about the remarkable process that transforms ordinary steel into a corrosion-resistant wonder material? Look no further, as we embark on an enlightening journey to understand the world of galvanization.view What are the commonly used surface finishing?September 27, 2023Surface finishing is to clean, sweep, deburr, de-grease, de-oxidize, etc., the surface of the workpiece, which is used to meet the corrosion resistance, abrasion resistance, decorative or other special functional requirements of the product.view

What are the commonly used surface finishing?September 27, 2023Surface finishing is to clean, sweep, deburr, de-grease, de-oxidize, etc., the surface of the workpiece, which is used to meet the corrosion resistance, abrasion resistance, decorative or other special functional requirements of the product.view Super-material carbon fiber: raw material production and its application and processingDecember 20, 2023Carbon fiber materials are used more and more widely, and their manufacturing is correspondingly accepted by more people. Price, capability and quality are all our advantages.view

Super-material carbon fiber: raw material production and its application and processingDecember 20, 2023Carbon fiber materials are used more and more widely, and their manufacturing is correspondingly accepted by more people. Price, capability and quality are all our advantages.view Can Titanium Be Machined: Comprehensive analysis of CNC machining of titanium materialsNovember 10, 2023Greetings, machining enthusiasts! Have you ever wondered if titanium, that resilient and lightweight metal, can truly be harnessed through CNC machining? I'm here to not only answer your burning question but to delve into the intricacies, challenges, and best practices associated with machining titanium. As Richconn, your go-to precision machine shop, let's unlock the full potential of this extraordinary material together.view

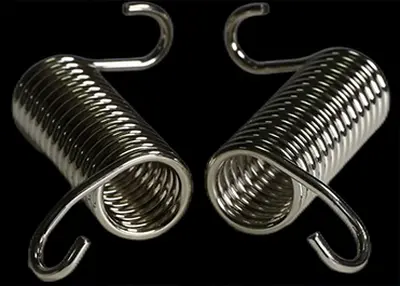

Can Titanium Be Machined: Comprehensive analysis of CNC machining of titanium materialsNovember 10, 2023Greetings, machining enthusiasts! Have you ever wondered if titanium, that resilient and lightweight metal, can truly be harnessed through CNC machining? I'm here to not only answer your burning question but to delve into the intricacies, challenges, and best practices associated with machining titanium. As Richconn, your go-to precision machine shop, let's unlock the full potential of this extraordinary material together.view The Tiny World of Springs: A Comprehensive Analysis of Their Types and ApplicationsSeptember 26, 2023Springs are an extremely important and common component in mechanical parts, excelling in enabling motion, shock absorption, providing controllable pushing force, pulling force, and flexible clearance...view

The Tiny World of Springs: A Comprehensive Analysis of Their Types and ApplicationsSeptember 26, 2023Springs are an extremely important and common component in mechanical parts, excelling in enabling motion, shock absorption, providing controllable pushing force, pulling force, and flexible clearance...view CNC Honing Service A Guide for Concept & SelectionMay 20, 2024CNC honing service helps to achieve tighter tolerances and better surface finishes on a wide range of precision machined parts with a round bore. Here's a simple guide for its concept and selection.view

CNC Honing Service A Guide for Concept & SelectionMay 20, 2024CNC honing service helps to achieve tighter tolerances and better surface finishes on a wide range of precision machined parts with a round bore. Here's a simple guide for its concept and selection.view

EN

EN

ru

ru