Stainless steel is easier to weld than aluminum.

This is because the melting point of stainless steel is higher than that of aluminum alloys, which makes it more stable during the welding process. Aluminum alloys are prone to the risk of being burned through because of their low melting point during the welding process. In addition, aluminum alloys are also susceptible to the formation of an aluminum oxide film on the surface in air, which has a much higher melting point than aluminum itself, making it more difficult to weld.

The weldability of metal materials refers to the ability of metal materials to obtain excellent welded joints under the conditions of using certain welding processes including welding methods, welding materials, welding specifications and welding structure forms. A metal, if you can use more common and simple welding process to obtain excellent welded joints, it is considered that this metal has good welding performance metal material weldability is generally divided into process weldability and use of weldability two aspects.

In fact, the weldability of metal materials is determined by a number of factors, such as material, process, structure, including the choice of welding process and welding conditions have an impact.

Material includes base material and welding material. Under the same welding conditions, the main factor determining the weldability of the base material is its own physical properties and chemical composition.

Such as the melting point of the metal, thermal conductivity, coefficient of linear expansion, density, heat capacity and other factors, all have an impact on thermal cycling, melting, crystallization, phase transition and other processes, thereby affecting the weldability. Stainless steel and other materials with low thermal conductivity, welding temperature gradient, high residual stress, deformation,. And because of the high temperature residence time is long, the heat affected zone grain growth, the joint performance is unfavorable. Austenitic stainless steel linear expansion coefficient is large, the deformation and stress of the joint is more serious.

One of the most influential is the carbon element, that is to say, the amount of carbon content of the metal determines its weldability. Most of the other alloying elements in steel are also unfavorable to welding, but the degree of their influence is generally much smaller than carbon. Increased carbon content in steel, the tendency to harden increases, while plasticity decreases, prone to weld cracks.

Usually, the sensitivity of the metal material in the welding cracks and changes in the mechanical properties of the welded joint area as the main indicator of the evaluation of the weldability of the material. So the higher the carbon content, the worse the weldability. Carbon content of less than 0.25% of mild steel and low alloy steel, excellent plasticity and impact toughness, welded joints after welding plasticity and impact toughness is also very good. Welding does not require preheating and post-weld heat treatment, the welding process is easy to control, so it has good weldability.

In addition, the steel smelting and rolling status, heat treatment status, organizational status, etc., to varying degrees, have an impact on the weldability. By means of refining and purification or grain refinement and controlled rolling process to improve the weldability of steel.

Welding material directly involved in the welding process a series of chemical metallurgical reaction, determines the composition of the weld metal, organization, performance and defect formation. If the choice of welding material is not appropriate, and the base material does not match, not only can not get to meet the requirements of the use of joints, but also the introduction of cracks and other defects and changes in organization and performance. Therefore, the correct selection of welding materials is an important factor to ensure that the quality of welded joints.

Process factors include welding methods, welding process parameters, welding sequence, preheating, post-heating and post-weld heat treatment. Welding method has a great influence on weldability, mainly in the heat source characteristics and protection conditions.

Different welding methods and its heat source in the power, energy density, maximum heating temperature, etc. There are great differences. Metal welding under different heat sources will show different welding properties.

Such as electroslag welding power is very large, but the energy density is very low, the maximum heating temperature is not high, slow heating when welding, high temperature stay a long time, so that the heat affected zone grain size, impact toughness is significantly reduced, must be normalized to improve. In contrast, electron beam welding, laser welding and other methods, the power is not large, but the energy density is very high, rapid heating. High temperature residence time is short, the heat affected zone is very narrow, there is no danger of grain growth.

Adjustment of welding process parameters, take preheating, post-heating, multi-layer welding and control of interlayer temperature and other process measures, you can regulate and control the welding thermal cycle, which can change the weldability of the metal. If you take measures such as preheating before welding or post-welding heat treatment, it is entirely possible to obtain no crack defects, to meet the requirements of the use of performance of the welded joints.

Mainly refers to the welding structure and welding joint design form, such as the structure shape, size, thickness, joint bevel form, weld layout and its cross-section shape and other factors on the impact of weldability. Its influence is mainly manifested in the heat transfer and force state.

Different plate thickness, different joint form or bevel shape of its heat transfer rate direction and heat transfer rate is not the same, thus the molten pool crystallization direction and grain growth occurs. The structure of the switch, plate thickness and the arrangement of the weld, etc., determines the stiffness and constraint of the joint, which has an effect on the stress state of the joint.

Poor crystallization pattern, severe stress concentration and excessive welding stress are the basic conditions for the formation of welding cracks. Design to reduce the stiffness of the joint, reduce the cross weld, reduce the various factors that cause stress concentration, are important measures to improve weldability.

Use conditions refers to the service period of the welded structure working temperature, load conditions and working medium. These working environment and operating conditions require that the welded structure has the corresponding performance. Such as working at low temperatures in the welded structure, must have brittle fracture resistance; working at high temperatures in the structure to have creep resistance; working under alternating loads in the structure has good fatigue resistance; in acid, alkali or salt media work of the welded containers should have a high corrosion resistance and so on. In short, the more demanding the conditions of use, the higher the quality requirements of welded joints, the material weldability is less easy to ensure.

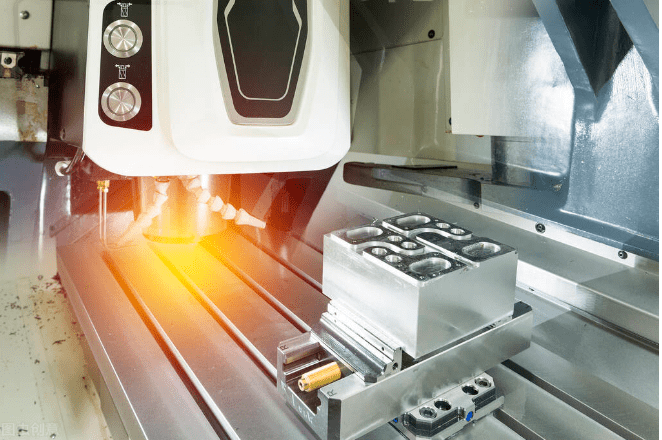

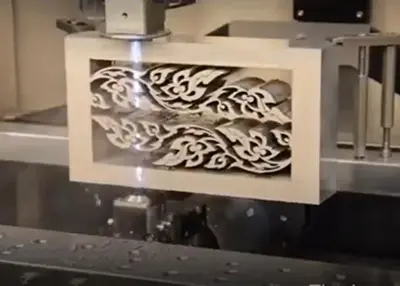

When creativity meets precision, Richconn skillfully manufactures! As a leading rapid prototyping company in China, we are committed to providing you with exceptional metal CNC machining and sheet metal services. No matter how complex your project needs to be, we can quickly realize your ideas and turn innovation into reality. Choose Richconn for quality and speed to start your manufacturing journey!

CNC Machined Motorcycle Parts: Precision Craftsmanship by RichconnNovember 14, 2023Rev up your expectations as we delve into the intricate world of CNC machined motorcycle parts. I'm excited to guide you through the details, showcasing how Richconn is your go-to source for precision solutions. Let's ride into the comprehensive exploration!view

CNC Machined Motorcycle Parts: Precision Craftsmanship by RichconnNovember 14, 2023Rev up your expectations as we delve into the intricate world of CNC machined motorcycle parts. I'm excited to guide you through the details, showcasing how Richconn is your go-to source for precision solutions. Let's ride into the comprehensive exploration!view What is CNC Milling Machine: Definition, Uses, Types & PricesMarch 29, 2024Let's delve deeper into CNC milling machine, which holds significant importance for your project, and explore the mill machine in detail.view

What is CNC Milling Machine: Definition, Uses, Types & PricesMarch 29, 2024Let's delve deeper into CNC milling machine, which holds significant importance for your project, and explore the mill machine in detail.view What five axes does the five axes machining center have?March 6, 2023Five-axis machining centers have long been important in the aerospace industry, where machined parts follow the aerodynamic form of the aircraft. Some machines move the rotary axis simply to position ...view

What five axes does the five axes machining center have?March 6, 2023Five-axis machining centers have long been important in the aerospace industry, where machined parts follow the aerodynamic form of the aircraft. Some machines move the rotary axis simply to position ...view How to Access Shaft Bearing and Housing Fit?May 23, 2024By describing the types of shafts, the steps for determining shaft fits, and other aspects of this article, the reader can gain a detailed understanding of how to determine bearing shaft and housing fits.view

How to Access Shaft Bearing and Housing Fit?May 23, 2024By describing the types of shafts, the steps for determining shaft fits, and other aspects of this article, the reader can gain a detailed understanding of how to determine bearing shaft and housing fits.view CNC Turning Process And Process AnalysisJune 21, 20221. The content of CNC turning processThe CNC turning process is the sum of the methods and technical means used when CNC lathes are used to process parts. Its main contents include the following aspec...view

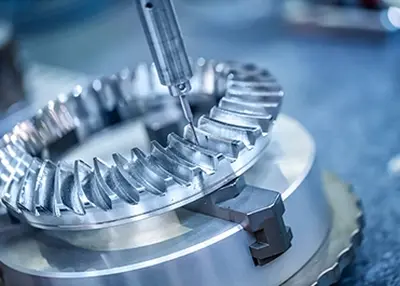

CNC Turning Process And Process AnalysisJune 21, 20221. The content of CNC turning processThe CNC turning process is the sum of the methods and technical means used when CNC lathes are used to process parts. Its main contents include the following aspec...view How Many Types of Gears Are There? What Common Materials Are Suitable for Making Gears?October 26, 2023Gears are mechanical parts with teeth that can mesh with each other, and they are widely used in mechanical transmission and the whole mechanical field. There are many types of gears, mainly reclusive gear axis classification, generally divided into parallel shaft, intersecting shaft and staggered shaft three types.view

How Many Types of Gears Are There? What Common Materials Are Suitable for Making Gears?October 26, 2023Gears are mechanical parts with teeth that can mesh with each other, and they are widely used in mechanical transmission and the whole mechanical field. There are many types of gears, mainly reclusive gear axis classification, generally divided into parallel shaft, intersecting shaft and staggered shaft three types.view

EN

EN

ru

ru