Are you ready to explore the cutting-edge world of CNC router machinery? Whether you are a seasoned professional in the field or someone just getting started, this comprehensive guide will equip you with the knowledge you need to harness the full potential of CNC router machinery. From understanding the fundamentals to exploring innovative services, let's dive in and take your CNC router experience to the next level.

Let's start with the basics. CNC router machinery stands for Computer Numerical Control router machinery, and it's a game-changer in the manufacturing industry. These machines use computer programming to execute precise cutting, carving, and shaping tasks on various materials. What sets CNC routers apart from traditional machines is their exceptional precision and automation.

Now that you've grasped the concept, let's move on to the specifics.

CNC router machinery comes in various forms, each tailored to specific applications and requirements. To help you make an informed choice, let's explore the different types:

| Type of CNC Router | Best Suited For | Key Features |

|---|---|---|

| Desktop CNC Routers | Small-scale projects and workshops | Compact, versatile, and user-friendly. |

| Vertical CNC Routers | Versatile applications in the industry | Offers precision and flexibility for a wide range of materials. |

| Laser Cutting CNC Routers | Intricate designs and precise cutting | Utilizes laser technology for fine detailing. |

| Woodworking CNC Routers | Crafting fine wooden details | Designed for woodworking tasks with precision. |

| Metalworking CNC Routers | Working with metals | Robust and durable construction for metal machining. |

| 3-Axis, 4-Axis, and 5-Axis CNC Routers | Multidimensional capabilities | Ideal for complex shapes and 3D carving. |

Each type of CNC router machinery has its unique advantages and is suitable for specific applications. Your choice should be based on your project requirements and materials to be processed.

Understanding the working principles of CNC router machinery is crucial to operating these machines effectively. Here, we'll delve into the key components and processes involved.

CAD Design and 3D Modeling: At the heart of CNC machining is computer-aided design (CAD) and 3D modeling. CAD software allows designers to create detailed, digital representations of the object to be machined. These digital models serve as the blueprints for the CNC machine.

The ABCs of G-Code Programming: G-Code is the language that CNC machines understand. It consists of a series of commands and coordinates that guide the machine's movements. Programmers use G-Code to translate the design into a set of instructions the CNC router can follow.

Motion Control Systems: CNC routers have complex motion control systems that coordinate the movement of the cutting tool. These systems use motors and feedback mechanisms to ensure precise and accurate motion. Understanding how these systems work is essential to achieving high-quality results.

Material Cutting and Carving: The actual cutting and carving process involves the movement of the cutting tool along the programmed path. The tool may be a rotating cutter, a laser, or another mechanism, depending on the type of CNC router. The machine precisely follows the G-Code instructions to remove material and create the desired shape or design.

By mastering these principles, you'll be better equipped to create and execute CNC machining programs effectively.

CNC router machinery finds applications in a wide range of industries, making it a versatile tool in modern manufacturing. Here are some of the key application areas:

Manufacturing Industry: CNC routers are widely used in the manufacturing sector to create precision components. From custom furniture to automotive parts, CNC routers play a pivotal role in producing high-quality products with tight tolerances.

Art and Creativity: The artistic and creative potential of CNC routers is immense. Artists and designers use these machines for sculpting, carving, and intricate detailing, giving life to their creative visions.

Education and Research: In educational institutions and research facilities, CNC routers serve as essential tools for innovation and academic exploration. They enable students and researchers to bring their ideas to life and conduct experiments with precision.

Understanding these diverse applications will help you appreciate the versatility of CNC router machinery and inspire you to explore how it can benefit your specific needs.

Selecting the right CNC router machinery is a critical decision, as it directly impacts the success of your projects. To make an informed choice, consider the following factors:

Brand and Model Comparison: Begin your selection process by researching and comparing various brands and models. Look for reputable manufacturers with a track record of producing reliable CNC routers. Each brand may offer multiple models with distinct features, so evaluate your options carefully.

Performance Specifications: Pay close attention to the performance specifications of the CNC routers you are considering. These specifications include the working area size, spindle power, feed rates, and resolution. Ensure that the machine's capabilities align with the requirements of your projects.

Budget and Costs: Determine your budget and factor in all associated costs, including the purchase price, installation, and any necessary accessories or tooling. While it's essential to stay within your budget, prioritize quality and performance to achieve long-term value.

Vendor Support and Training: Choosing a vendor with excellent customer support and training programs is crucial. Ensure that the vendor offers comprehensive training, technical support, and readily available spare parts. Access to a reliable support network will help you address any challenges that may arise during the machine's operation.

Your selection process should be a well-informed one, balancing your project requirements and budget constraints. Remember that investing in a high-quality CNC router will pay off in the long run through improved performance and reduced maintenance costs.

To ensure the longevity and optimal performance of your CNC router machinery, a regular maintenance routine is essential. Let's break down the key aspects of maintaining your CNC router:

Daily Maintenance Routine: A daily maintenance routine involves tasks such as cleaning the machine, checking for loose fasteners, and inspecting the cutting tools. Regularly removing debris and dust from the machine's components ensures smooth operation and prevents premature wear.

Common Issues and Troubleshooting: Despite regular maintenance, issues can arise. Common problems may include misalignment, tool wear, or electronic glitches. Familiarize yourself with these potential problems and their solutions to address them promptly.

Prolonging Machine Lifespan: Implementing practices that extend the lifespan of your CNC router is crucial. This includes using appropriate cutting speeds and feeds, properly securing workpieces, and ensuring the machine operates within its specified limits.

By adhering to a maintenance regimen and promptly addressing issues, you'll enjoy consistent performance and prolong the life of your CNC router machinery.

Now, let's explore Rihconn, a leading CNC machining service provider based in China, renowned for its precision and reliability. Rihconn offers a range of exceptional services designed to meet your unique needs.

Rihconn is a Chinese rapid prototyping companies specializing in delivering precision manufacturing solutions to clients worldwide. With a focus on quality, accuracy, and customization, Rihconn is committed to providing the best CNC machining services available.

| Rihconn Precision Manufacturing Services |

|---|

| Precision CNC Milling and Precision Turning: Precision machining of a wide range of materials, producing parts with tight tolerances. |

| Prototyping: Rapid prototyping services to bring your concepts to life for testing and evaluation. |

| Custom Fabrication: Tailored manufacturing solutions to meet your specific project requirements. |

| Quality Assurance: Rigorous quality control processes ensure that every product meets the highest standards. |

| Timely Delivery: Efficient production processes ensure your projects are delivered on schedule. |

Rihconn's precision manufacturing services encompass CNC milling, turning, prototyping, custom fabrication, quality assurance, and timely delivery. With state-of-the-art equipment and a team of skilled professionals, Rihconn is dedicated to meeting your CNC machining needs with precision and efficiency.

What sets Rihconn apart in the CNC machining industry? Let's take a closer look at the core advantages and features that make Rihconn a standout choice:

High Precision: Rihconn is renowned for its commitment to precision. Utilizing advanced CNC machining technology, the company consistently delivers parts and components with tight tolerances.

Customization: Rihconn understands that every project is unique. The company's services are highly customizable to meet the specific requirements of your project, ensuring you get exactly what you need.

Quality Control: Rihconn places a strong emphasis on quality assurance. Rigorous quality control processes are integrated into every stage of production to guarantee the highest product quality.

Timely Delivery: Efficiency is a top priority at Rihconn. The company's streamlined production processes ensure that your projects are completed and delivered on time, meeting your project schedules.

Ready to explore the precision manufacturing services offered by Rihconn? To get in touch with Rihconn and take the next step in realizing your CNC machining projects, use the contact information below:

Website:https://www.richconn-cnc.com/

Email: sales@richconn.com.cn

Phone:+86-0755-28025755

By choosing Rihconn, you gain a trusted partner in CNC machining, offering top-notch services and a commitment to excellence.

In conclusion, CNC router machinery is the backbone of modern manufacturing, and understanding its intricacies is essential for anyone in the field. From selecting the right machine to exploring innovative services like Rihconn Precision Manufacturing, your CNC journey is full of opportunities. Keep exploring, keep innovating, and embrace the future of manufacturing. Your journey begins now!

Unlocking the World of Machined Bushes: Your Comprehensive GuideNovember 8, 2023Are you ready to delve into the fascinating world of machined bushes? If you're curious about what machined bushes are, how they are made, where they are used, and how to choose the right ones for your specific needs, you've come to the right place. I'm here to guide you through this journey of discovery.view

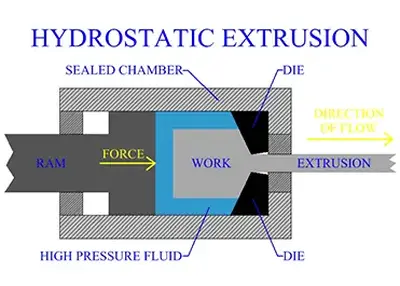

Unlocking the World of Machined Bushes: Your Comprehensive GuideNovember 8, 2023Are you ready to delve into the fascinating world of machined bushes? If you're curious about what machined bushes are, how they are made, where they are used, and how to choose the right ones for your specific needs, you've come to the right place. I'm here to guide you through this journey of discovery.view Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view

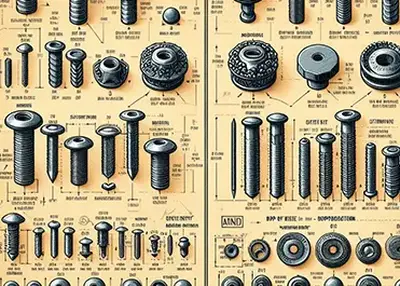

Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view Pop Rivets vs. Blind Rivets: A Comparison of Two Common FastenersNovember 28, 2023Fasteners are devices that are used to join or hold two or more materials or parts together. There are many types and categories of fasteners, such as screws, bolts, nuts, washers, nails, pins, etc.view

Pop Rivets vs. Blind Rivets: A Comparison of Two Common FastenersNovember 28, 2023Fasteners are devices that are used to join or hold two or more materials or parts together. There are many types and categories of fasteners, such as screws, bolts, nuts, washers, nails, pins, etc.view Find the Right Corrosion Resistant MetalsOctober 16, 2023Without oxygen, no living thing could exist on Earth. Yet it is indeed a toxic, highly corrosive gas that can even be used to propel rockets into space. Our bodies make use of oxygen in impressive ways. The fact that the air we breathe contains only a relatively small proportion of the gas - about 21 percent oxygen compared with 78 percent nitrogen - also helps keep us alive.view

Find the Right Corrosion Resistant MetalsOctober 16, 2023Without oxygen, no living thing could exist on Earth. Yet it is indeed a toxic, highly corrosive gas that can even be used to propel rockets into space. Our bodies make use of oxygen in impressive ways. The fact that the air we breathe contains only a relatively small proportion of the gas - about 21 percent oxygen compared with 78 percent nitrogen - also helps keep us alive.view How to Remove Chrome Plating Easily? (A Complete Guide 2024)March 11, 2024Learn how to remove chrome plating effectively with our comprehensive guide and get expert tips for successfully stripping chrome from metal surfaces.view

How to Remove Chrome Plating Easily? (A Complete Guide 2024)March 11, 2024Learn how to remove chrome plating effectively with our comprehensive guide and get expert tips for successfully stripping chrome from metal surfaces.view 3-Axis Vs 4-Axis Vs 5-Axis CNCJuly 21, 20233-axis machiningThree axis CNC machining is the most basic, commonly used in the machinery manufacturing industry is one of the most important processing methods. Common understanding is: accurate lin...view

3-Axis Vs 4-Axis Vs 5-Axis CNCJuly 21, 20233-axis machiningThree axis CNC machining is the most basic, commonly used in the machinery manufacturing industry is one of the most important processing methods. Common understanding is: accurate lin...view

EN

EN

ru

ru