In the intricate world of CNC machining, understanding the nuances of UNF Threads and UNC Threads is paramount. These threading standards, Unified National Fine (UNF) and Unified National Coarse (UNC), serve as the bedrock of precision in mechanical engineering. Let's delve into the specifics, exploring their applications, differences, and the critical role they play in the realm of precision machining.

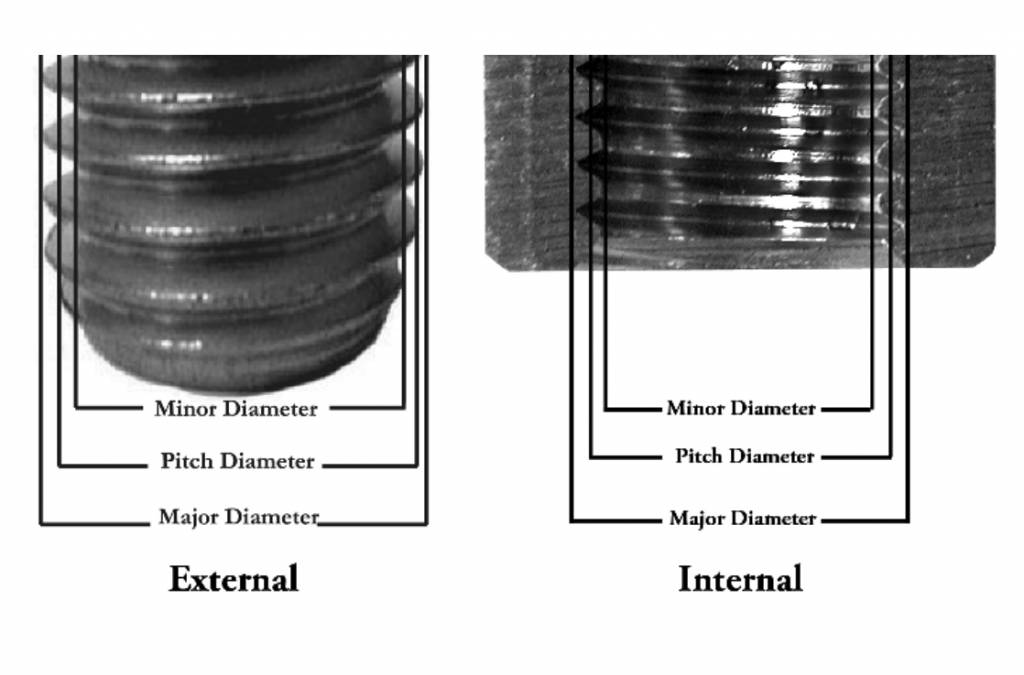

Unified National Fine (UNF) Threads and Unified National Coarse (UNC) Threads form the backbone of precision in machining. UNF Threads are characterized by tighter tolerances and finer pitches, making them suitable for applications demanding the utmost precision. On the other hand, UNC Threads, with their coarser pitches, prioritize strength in connections over fine-tuned precision.

To put it into perspective, consider a scenario where a delicate instrument requires a secure yet precise connection. UNF Threads would be the natural choice, ensuring a snug fit with minimal play. In contrast, UNC Threads might find their application in situations where robustness and strength are paramount, such as heavy machinery or structural components.

Let's now explore the distinctions between UNF and UNC Threads in finer detail.

The key to optimizing machining processes lies in understanding the distinctions between UNF and UNC Threads. UNF Threads, with their finer pitches and tighter tolerances, provide a more delicate grip, ideal for scenarios where precision is non-negotiable. In contrast, UNC Threads, with their coarser pitches, offer a more robust connection, suitable for applications where strength is the primary concern.

In machining, the choice between UNF and UNC Threads can significantly impact the final product's quality and performance. Imagine a scenario where a CNC machine is tasked with creating intricate components for aeronautical engineering. In this case, UNF Threads would be the preferred choice, ensuring the precision required for such critical applications.

Let's dive deeper into the technical specifications of UNF and UNC Threads.

Technical specifications serve as the guiding principles for precision machining. For UNF Threads, these specifications include thread dimensions, tolerances, and angle measurements. The finer details in these specifications make UNF Threads ideal for applications where every micron matters.

Consider the manufacturing of medical devices where precision is non-negotiable. UNF Threads, with their meticulous specifications, ensure that components fit seamlessly, meeting the stringent requirements of the medical industry.

UNC Threads, with their coarser specifications, find their niche in applications where a balance between strength and precision is crucial. Think of a scenario in automotive manufacturing, where components need to withstand external forces while maintaining a level of precision. UNC Threads provide the necessary equilibrium in such situations.

The practical implementation of UNF and UNC Threads in CNC machining is where theory meets reality. Selecting the appropriate threading standard can make or break the precision and efficiency of the machining process.

In CNC machining, the choice between UNF and UNC Threads often hinges on the specific requirements of the project. Let's consider a scenario where a CNC machine is tasked with crafting components for aerospace engineering. UNF Threads, with their fine precision, become the natural choice, ensuring the intricate parts meet the stringent demands of aerospace applications.

Conversely, when the emphasis is more on durability and reliability in a CNC machining process, UNC Threads step into the spotlight. Industries like heavy equipment manufacturing rely on UNC Threads to withstand immense pressure and stress while maintaining a functional and reliable connection.

To optimize CNC machining processes, it's crucial to understand the project's intricacies, material characteristics, and the expected stress levels the components will endure. By aligning these factors with the appropriate threading standard, manufacturers can achieve the desired precision and durability in their final products.

Let's explore the toolkit essential for utilizing UNF and UNC Threads in CNC machining.

The efficacy of UNF and UNC Threads in CNC machining is significantly enhanced by the tools and resources employed in the process. Precision cutting tools, thread gauges, calipers, and specialized CNC machines equipped to handle different threading standards become indispensable assets.

Here's a snapshot of the essential tools:

| Tool | Description |

|---|---|

| Precision Cutting Tools | End mills, taps, and dies designed for fine threading and accuracy |

| Thread Gauges | Ensures conformity to specified thread standards |

| Calipers | Precision measuring instruments for accurate thread dimensions |

| CNC Machines | Configured to handle UNF and UNC Thread specifications |

Suppose a CNC precision machine shop aims to enhance its capabilities in UNF and UNC Threads. In that case, investing in these tools and ensuring they meet industry standards becomes paramount. Accurate measurement and precision machining tools guarantee the adherence to the strict tolerances demanded by UNF Threads and the durability offered by UNC Threads.

Real-world applications often exemplify the practical advantages of employing UNF and UNC Threads in manufacturing. These success stories highlight the prowess of precision machining when the right threading standards are meticulously chosen and applied.

Consider an automotive assembly line where the use of UNF Threads in critical components significantly enhances vehicle performance. The precise fit provided by UNF Threads ensures the integrity of parts, contributing to the overall reliability and safety of the vehicle. Manufacturers leveraging UNF Threads in such scenarios yield vehicles with enhanced durability and reduced maintenance issues.

In contrast, UNC Threads shine in heavy machinery manufacturing, where robustness and reliability are pivotal. Equipment designed with UNC Threads withstands harsh operational conditions, offering longevity and minimal risk of structural failures. Industries relying on heavy machinery, such as construction and mining, benefit immensely from the resilience provided by UNC Threads.

Exploring these success stories underlines the versatility of UNF and UNC Threads across diverse industries. Their ability to cater to specific requirements while ensuring precision or strength positions them as indispensable standards in the manufacturing landscape.

Let's pivot our focus to Richconn's expertise in UNF and UNC Thread machining services.

Richconn, a vanguard in precision machining, boasts unparalleled expertise in UNF and UNC Thread CNC machining services. Our commitment to delivering exceptional quality, coupled with advanced machining capabilities, positions us as a preferred partner for precision manufacturing needs.

Our suite of services encompasses:

Tailored Solutions: Richconn offers bespoke machining solutions tailored to specific UNF and UNC Thread requirements. Whether it's delicate components demanding UNF precision or robust structures necessitating UNC strength, our expertise ensures superior results.

Quality Assurance: With stringent quality control measures, every component manufactured at Richconn undergoes rigorous testing to meet and exceed industry standards. Our commitment to precision and durability is ingrained in every product we deliver.

Client Success Stories: Collaborations with a diverse clientele across industries showcase Richconn's prowess in implementing UNF and UNC Threads to achieve superior results. Our track record speaks volumes about our ability to cater to multifaceted machining needs.

Let's now explore the depth of Richconn's specialized services in UNF and UNC Threads.

In the world of precision machining, the intricate dance between UNF and UNC Threads sets the stage for excellence. The journey through the nuances of these threading standards has illuminated their indispensable roles in achieving precision, durability, and reliability across various industries.

From understanding the finer technicalities to exploring real-world applications, the significance of choosing the right threading standard for CNC machining cannot be overstated. Whether it's UNF Threads offering unparalleled precision or UNC Threads providing robustness, the choice impacts the quality and performance of the final product.

The Working Principle of CNC Cutting Aluminum SheetsFebruary 29, 2024The Intricacies of CNC Cutting Aluminum SheetsIn the intricate world of manufacturing and fabrication, CNC cutting aluminum sheets has become a cornerstone practice, heralding a new era of precision a...view

The Working Principle of CNC Cutting Aluminum SheetsFebruary 29, 2024The Intricacies of CNC Cutting Aluminum SheetsIn the intricate world of manufacturing and fabrication, CNC cutting aluminum sheets has become a cornerstone practice, heralding a new era of precision a...view What is a CNC Machine?October 20, 2023The full name of CNC is Computer Numerical Control, and a tooling machine with a computer as the control center is called a CNC machine. The traditional tooling machines need to be manually operated to achieve a variety of metal processing techniques, CNC machine is by the engineers of the computer input product drawings, complete the product required tooling sequence, processing environment parameters and other data, by the computer according to the above instructions for automated production.view

What is a CNC Machine?October 20, 2023The full name of CNC is Computer Numerical Control, and a tooling machine with a computer as the control center is called a CNC machine. The traditional tooling machines need to be manually operated to achieve a variety of metal processing techniques, CNC machine is by the engineers of the computer input product drawings, complete the product required tooling sequence, processing environment parameters and other data, by the computer according to the above instructions for automated production.view How Much Does Injection Molding Cost?August 9, 2023Injection molding is a widely used manufacturing process for the production of components and products. As with any manufacturing process, it is crucial to understand the cost factors involved in inje...view

How Much Does Injection Molding Cost?August 9, 2023Injection molding is a widely used manufacturing process for the production of components and products. As with any manufacturing process, it is crucial to understand the cost factors involved in inje...view Demystifying CNC Lathe Machining – Unveiling the Precision PowerhouseNovember 3, 2023In the heart of precision manufacturing, CNC (Computer Numerical Control) lathe machining stands as a true marvel. It's a technology that has transformed the way we create parts and components across various industries.view

Demystifying CNC Lathe Machining – Unveiling the Precision PowerhouseNovember 3, 2023In the heart of precision manufacturing, CNC (Computer Numerical Control) lathe machining stands as a true marvel. It's a technology that has transformed the way we create parts and components across various industries.view Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view

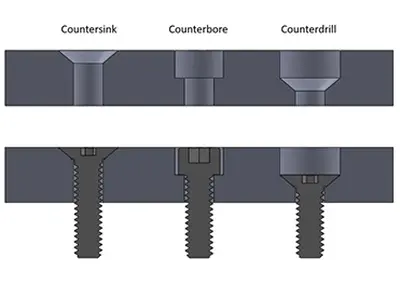

Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view What is Counter Sink? Your Comprehensive GuideOctober 8, 2023A countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material.view

What is Counter Sink? Your Comprehensive GuideOctober 8, 2023A countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material.view

EN

EN

ru

ru