When fabricating prototypes or genuine components for any product, the dimensions and geometric attributes of the parts hold utmost significance. The dimensions' inaccuracies can potentially compromise the entire production process, which is why we've developed a high-tolerance measuring machine. Here, we're introducing this machine to address the question, "What is CMM Machine?"

The CMM machine serves as a crucial instrument in the manufacturing process, ensuring a smooth workflow. This article aims to provide comprehensive insights into the CMM machine, addressing queries such as its functionality, applications, components, advantages, and limitations. By the end of this article, you will have a fundamental understanding of this machine.

In every manufacturing process, precise geometric and physical dimensions are paramount. Typically, two methods are employed for achieving this accuracy: the traditional approach, which involves utilizing measuring hand tools or optical comparators, but these tools often require expertise and are prone to numerous errors; and the utilization of a CMM machine.

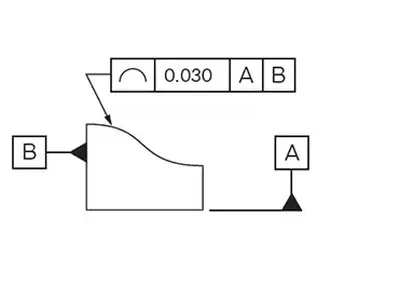

What does CMM stand for? The abbreviation CMM stands for Coordinate Measuring Machine, a device that employs coordinate technology to assess the dimensions of CMM machinery or tool components. This includes determining height, width, and depth along the X, Y, and Z axes. The sophistication of the CMM machine determines its capability to measure targets and record the obtained data.

After addressing the inquiry about the nature of a CMM machine, it is crucial to comprehend its significance in every manufacturing process. This understanding involves grasping the differences between the traditional and contemporary methods in terms of their operational efficiencies.

The traditional approach to measuring parts is fraught with limitations. For instance, it heavily relies on the operator's experience and skill, and without it, the produced parts may fall short of the required quality. Furthermore, with the advent of increasingly sophisticated parts in this century, the need for a more advanced measurement technique has arisen. This is where the CMM machine excels. Possessing both speed and accuracy, it outperforms the traditional method in repeatedly measuring parts. Additionally, it boosts productivity while minimizing the risk of errors during the measurement process. In essence, understanding what a CMM machine is, its necessity, and how to utilize it effectively will not only save time and money but also enhance your company's reputation and image.

Understanding the essence of a CMM machine involves grasping its operational principles. Generally, CMM machines employ two distinct methods for measurement: one utilizes a contact mechanism, such as touch probes, to assess tool parts, while the other employs alternative techniques like cameras or lasers. Additionally, there's a variance in the scope of parts that can be measured, with some models, like automotive CMM machines, capable of handling parts exceeding 10 meters in size.

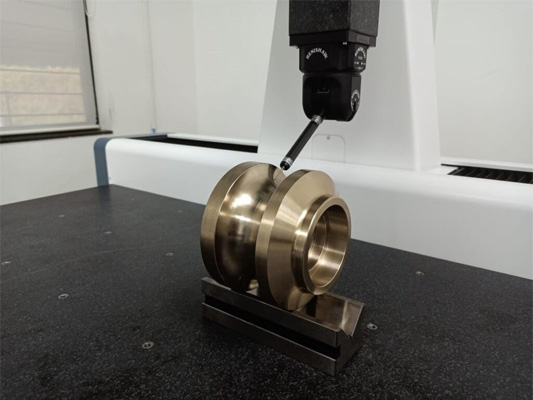

A CMM performs dual functions: it determines an object's physical geometry and dimensions using a touch probe mounted on its movable axis, and it verifies that the parts conform to the intended design. The operation of a CMM involves several steps. Initially, the part to be measured is placed on the CMM's base, a stable and rigid platform made of dense material to ensure accurate measurements despite external disturbances. Above this base, a movable gantry equipped with a touch probe is installed. The optical CMM then controls the gantry, guiding the probe along the X, Y, and Z axes to replicate every detail of the part, thus facilitating precise measurement.

Upon contacting a point on the part to be measured, the probe transmits an electrical signal that the computer subsequently maps. By repeatedly performing this action across numerous points on the part, accurate measurements are achieved. Following the measurement process, the next phase involves analysis. Once the probe has captured the part's X, Y, and Z coordinates, the collected data is analyzed to construct features. Notably, the operational mechanism remains identical for CMM machines that utilize camera or laser systems for measurement.

To Know about a CMM machine, the functions of its components will always come into mind.

The following are the significant components of the CMM machine.

1. Probe

Probes serve as the pivotal and indispensable component of traditional CMM machines, executing critical measurement tasks. Alternative CMM machines employ optical light, cameras, lasers, and other technologies. Given their functional requirements, probe tips are fabricated from rigid and stable materials that are also resilient to temperature variations, ensuring consistent size regardless of temperature changes. Common materials used include ruby and zirconia, and the tips can be designed as spherical or needle-shaped to suit specific measurement needs.

2. Granite

The granite table, a crucial element of the CMM machine, ensures exceptional stability and precision in measurements. Unaffected by temperature fluctuations and boasting a lower rate of wear and tear compared to other materials, granite maintains its shape consistently over time, thus ideal for achieving highly accurate measurement results.

3. Fixture

Fixtures play a crucial role in manufacturing operations, serving as stabilizers and supporters. As integral components of the CMM machine, they securely fix parts in place, ensuring accurate measurements. Moving parts can introduce measurement errors, thus the importance of fixtures. Additionally, other fixing tools such as fixture plates, clamps, and magnets are also available to aid in securely positioning parts.

4. Air Compressors and Dryers

Standard bridge or gantry-type CMM machines commonly include air compressors and dryers as integral components.

5. Software

Although the software is not a physical component, it is nonetheless categorized as a crucial element of the system. Its significance lies in its ability to analyze probes and other sensitivity components, thus playing a pivotal role in the overall functionality of the system.

CMM machines ought to be a fundamental component of any production process, given their numerous advantages that outweigh any potential limitations. In this section, we will delve into both the benefits and constraints of CMM machines.

1. Time and money-saving

The CMM machine is indispensable to the production flow due to its unmatched speed and precision. As the manufacturing industry increasingly produces intricate tools, the CMM machine stands out as the ideal tool for accurately measuring their dimensions. Its utilization ultimately results in reduced production costs and time, further enhancing its value in the manufacturing process.

2. Guaranteed Quality Assurance

In contrast to traditional methods of measuring machine parts' dimensions, the CMM machine offers unparalleled reliability. It digitally measures and analyzes components, providing services such as dimensional analysis, CAD comparison, tool certifications, and reverse engineering. These capabilities are essential for ensuring quality assurance throughout the manufacturing process.

3. Versatile with Multiple Probes and Techniques

The CMM machine demonstrates versatility in its compatibility with various tools and components, regardless of their intricacy. This ensures that the machine can measure even the most complex parts with precision and accuracy.

4. Less Operator Involvement

A CMM machine, being computer-controlled, minimizes the need for human personnel, thereby reducing the likelihood of operational errors that can potentially cause problems.

While CMM machining machines undoubtedly enhance production workflow and occupy a pivotal role in manufacturing, they do possess certain limitations that one should take into account. Listed below are a few of these limitations.

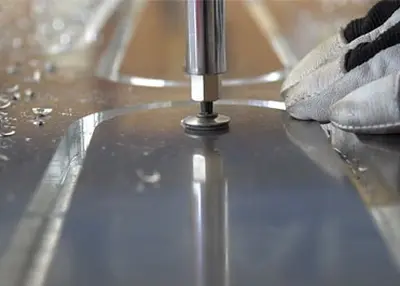

1. The Surface Will be Touched by the Probe

All CMM machines utilizing probes operate on a similar mechanism, requiring the probe to physically contact the surface of the part for measurement. While this poses no problem for highly durable parts, it can become problematic for parts with fragile or delicate finishes, as repeated contact may lead to deterioration of the part.

2. Defects Will be Caused by Soft Parts

Employing a probe to measure parts made from soft materials such as rubbers and elastomers can result in the parts collapsing inward, thereby introducing errors during digital analysis.

3. The Right Probe Must Be Selected

CMM machines utilize various types of probes, and it is crucial to choose the most suitable one for the task. The selection of the right probe greatly depends on factors such as the part's dimensions, the desired design, and the probe's capabilities.

CMM equipment is a tool utilized for measuring the physical and geometric characteristics of machine parts. This article aims to educate you about the CMM machine, encompassing its operation, components, advantages, and limitations. While understanding the machine's functionality is crucial, integrating it into the manufacturing process can pose a challenge. One straightforward approach is to outsource this task, and if you choose this route, Richconn stands as your optimal partner.

At Richconn, we offer a wide range of CMM machines. Whether it's for dimensional analysis of a single machine part or integration with manufacturing processes like CNC machining, injection molding, or 3D printing, we offer convenient online quotations and short lead times at competitive costs. So, if you're seeking seamless operations and high-quality results at an affordable price, Richconn is your ideal choice.

CNC numerical control cutting aluminum sheet, the efficient tool of modern manufacturingAugust 4, 2023In modern manufacturing, aluminum sheets are widely used, and CNC (Computer Numerical Control) cutting technology has become an efficient tool for processing aluminum sheets. CNC cutting aluminum she...view

CNC numerical control cutting aluminum sheet, the efficient tool of modern manufacturingAugust 4, 2023In modern manufacturing, aluminum sheets are widely used, and CNC (Computer Numerical Control) cutting technology has become an efficient tool for processing aluminum sheets. CNC cutting aluminum she...view Unveiling Precision: Mastering Surface Profile for Engineering ExcellenceNovember 21, 2023Engineering precision is more than a requirement; it's a commitment to excellence. Amidst the intricate world of engineering, understanding the nuances of surface profile becomes paramount.view

Unveiling Precision: Mastering Surface Profile for Engineering ExcellenceNovember 21, 2023Engineering precision is more than a requirement; it's a commitment to excellence. Amidst the intricate world of engineering, understanding the nuances of surface profile becomes paramount.view How to Go About Choosing an Aluminum Alloy Mechanical Keyboard Shell Processing Manufacturer?October 26, 2023For computer enthusiasts, the mechanical keyboard's metal texture and the sound of that mechanical equipment is a keyboard users a kind of enjoyment, mechanical keyboard bezel styling design is one of my favorite hardware configurations, especially glazed, computer typing is very indulgent.view

How to Go About Choosing an Aluminum Alloy Mechanical Keyboard Shell Processing Manufacturer?October 26, 2023For computer enthusiasts, the mechanical keyboard's metal texture and the sound of that mechanical equipment is a keyboard users a kind of enjoyment, mechanical keyboard bezel styling design is one of my favorite hardware configurations, especially glazed, computer typing is very indulgent.view Material Properties in More DetailOctober 18, 2023The functionality of a part is largely dependent on obvious factors such as shape, size, wall thickness, joints, etc. Less obvious, but equally important, are the properties of the material from which it is injection molded, CNC machined, or 3D printed (cut, bent, formed, etc.).view

Material Properties in More DetailOctober 18, 2023The functionality of a part is largely dependent on obvious factors such as shape, size, wall thickness, joints, etc. Less obvious, but equally important, are the properties of the material from which it is injection molded, CNC machined, or 3D printed (cut, bent, formed, etc.).view CNC Piston Machining: Crafting High-Quality Engine ComponentsNovember 7, 2023Are you in pursuit of engine components that combine precision, reliability, and performance? Your quest for top-notch CNC piston machining ends here. In this comprehensive guide, I will take you on a journey through the intricacies of CNC piston machining, shedding light on the processes, technologies, and services that define this critical aspect of engine manufacturing.view

CNC Piston Machining: Crafting High-Quality Engine ComponentsNovember 7, 2023Are you in pursuit of engine components that combine precision, reliability, and performance? Your quest for top-notch CNC piston machining ends here. In this comprehensive guide, I will take you on a journey through the intricacies of CNC piston machining, shedding light on the processes, technologies, and services that define this critical aspect of engine manufacturing.view Some Knowledge You Need to Learn About Design for ManufacturingFebruary 22, 2024Design for Manufacturing (DFM) is a set of best practices that aim to minimize manufacturing errors by focusing on mitigating defects and assessing the quality and dependability of supply chains.view

Some Knowledge You Need to Learn About Design for ManufacturingFebruary 22, 2024Design for Manufacturing (DFM) is a set of best practices that aim to minimize manufacturing errors by focusing on mitigating defects and assessing the quality and dependability of supply chains.view

EN

EN

ru

ru