In the intricate world of engineering, precision reigns supreme. Enter the realm of cylindricity - a fundamental attribute dictating the perfection of cylindrical forms. Here, I guide you through an explorative journey, unveiling the essence of cylindricity, its nuanced applications in GD&T (Geometric Dimensioning and Tolerancing), and the crucial methods to measure and comprehend this vital parameter.

Cylindricity, the epitome of geometric perfection, defines the degree of deviation of a cylindrical form from an ideal cylinder. It encapsulates not just roundness but the alignment and straightness of the axis as well. A deeper understanding of this concept unveils its paramount importance in ensuring optimal functionality across engineering domains.

Take the first step towards precision engineering—grasp the core essence of cylindricity and its role in defining perfection.

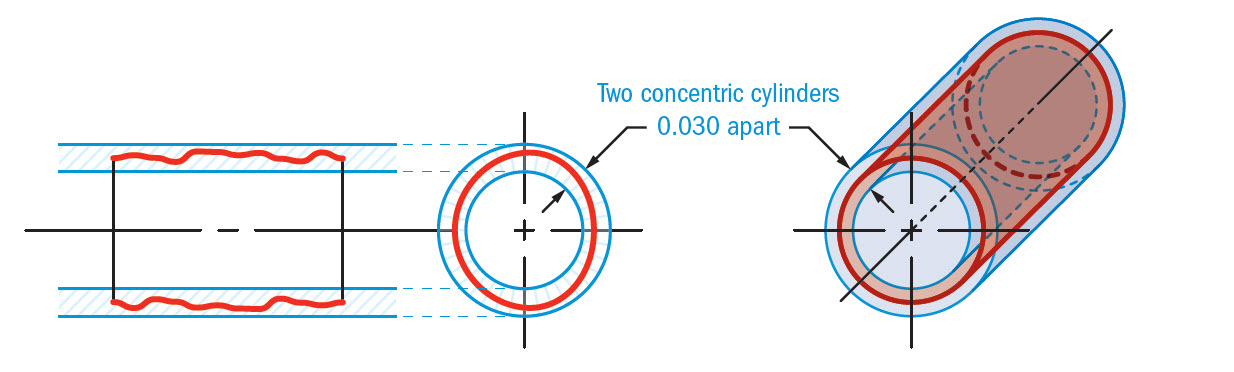

The foundational aspect of cylindricity lies in comprehending its essence beyond a mere geometric attribute. Picture a cylinder, not merely as a round object but as a meticulously crafted element where each deviation from perfection holds significance. In essence, cylindricity encapsulates the concentricity of the cylindrical feature, ensuring that the axis is not only straight but also aligned with the ideal axis.

Understanding cylindricity’s intricacies involves exploring its impact on various engineering applications. Consider a scenario in manufacturing, where the production of engine components demands not just round cylinders but ones with precisely aligned axes. Cylindricity becomes the guiding principle, ensuring that these components function seamlessly, meeting stringent performance standards.

The nuances of cylindricity extend beyond the manufacturing floor, permeating fields like aerospace and automotive engineering. In aircraft design, for instance, the alignment of engine components plays a pivotal role in aerodynamic efficiency. Cylindricity, therefore, becomes a critical factor, dictating the success of these engineering marvels. It's not just about round shapes; it's about precision in every dimension.

Embark on a journey to unravel the intricacies—explore the significance of cylindricity beyond its geometric definition.

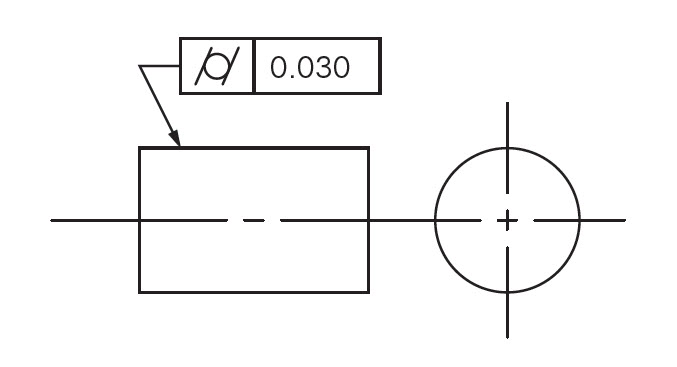

Continuing our exploration, let's delve into the mathematical representation of cylindricity. In GD&T, cylindricity is symbolized by a unique glyph, often perplexing to the uninitiated. Deciphering this symbol is akin to decoding a language specific to precision engineering. Each curve and line in the symbol holds a meaning—aligning with the real-world requirements of perfection.

Master the language of precision—understand the symbology of cylindricity in GD&T for flawless communication.

Understanding the representation is not merely a theoretical exercise; it's a practical necessity. Imagine a manufacturing scenario where the blueprint serves as the guiding document for creating a critical component. The cylindricity symbol on the blueprint becomes the communicator, conveying the stringent requirements for perfection. A minor misinterpretation could lead to deviations that impact the final product's functionality.

Let's further break down the symbol: the concentric circles and lines represent not just the roundness of the cylinder but also the allowable deviations from the ideal shape. Each element has a tolerance value, emphasizing the precision required in every dimension. It's a meticulous dance of mathematical language and practical application, ensuring that engineering specifications translate seamlessly into tangible products.

Decode the geometric language—unravel the intricacies of the cylindricity symbol for precise manufacturing.

As we navigate through the labyrinth of cylindricity, it becomes evident that this geometric attribute is not a standalone concept but an integral part of a broader spectrum. The next segment will unravel the symbiotic relationship between cylindricity and circularity—two seemingly similar yet distinctly different facets of geometric perfection. Join me in the exploration of their nuances and the critical distinctions that shape engineering precision.

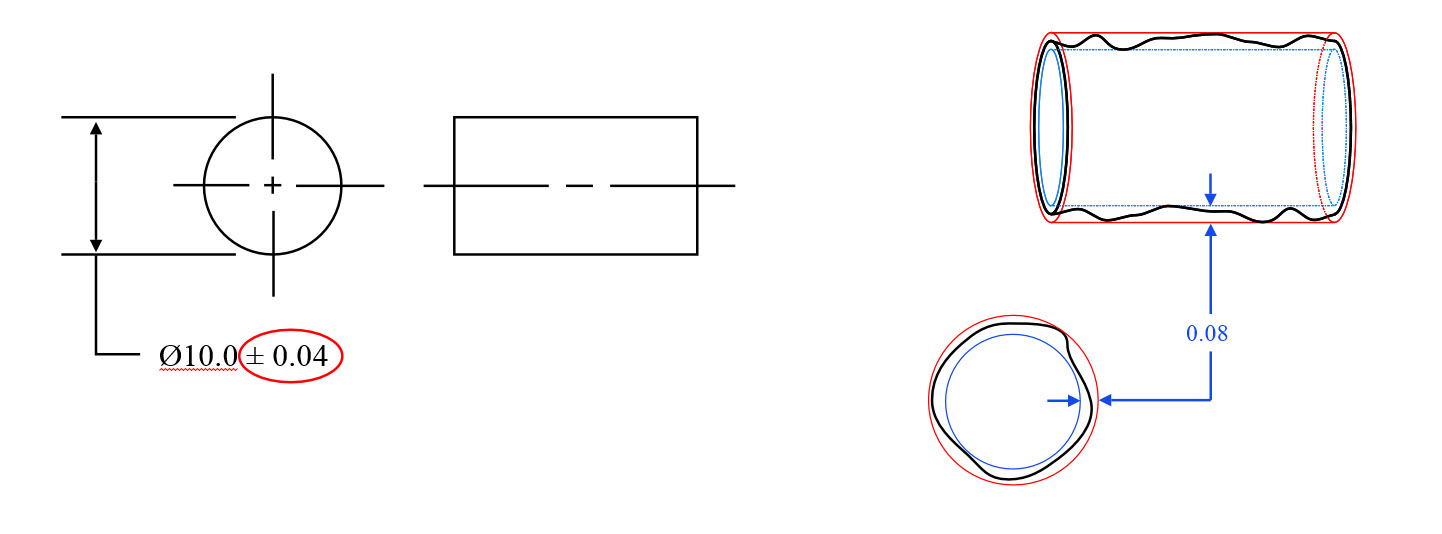

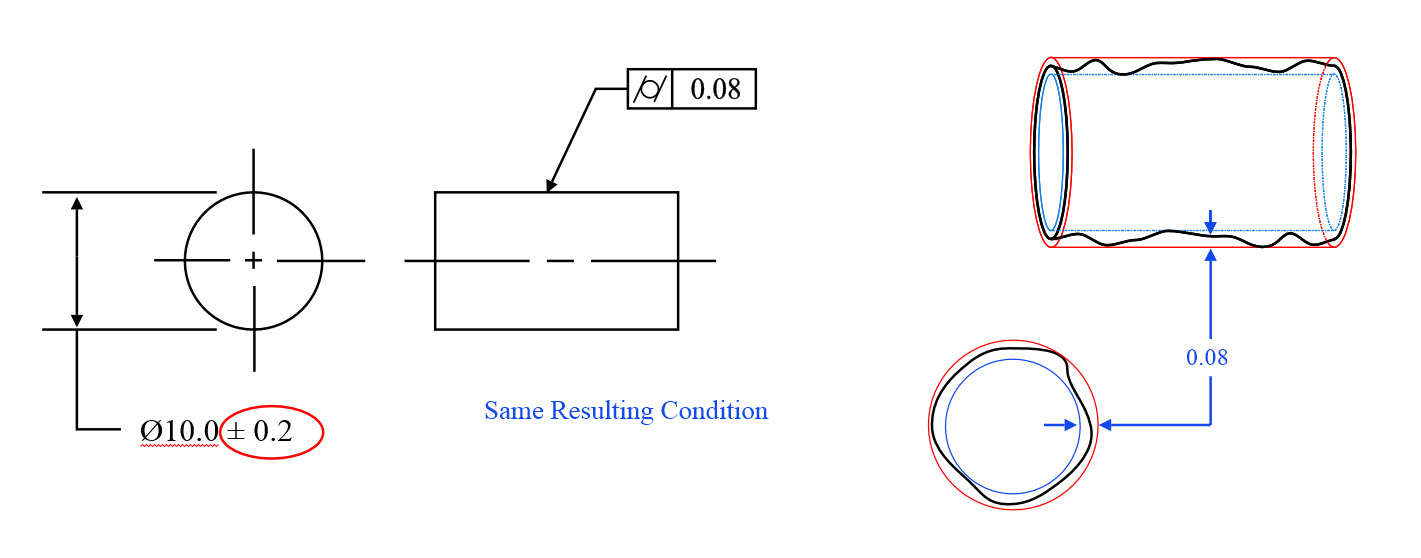

At first glance, cylindricity and circularity might seem synonymous, both revolving around the notion of roundness. However, a closer inspection reveals the subtle yet crucial differences between these two geometric attributes.

Cylindricity extends beyond the mere roundness of a cylindrical object. It encapsulates not just the perfect circular shape but also the alignment and straightness of its axis concerning an ideal cylinder. It scrutinizes deviations along the entire length of the cylindrical feature, ensuring not just circularity but also precision in orientation and alignment.

On the other hand, circularity primarily focuses on assessing the roundness of a cross-section or a circular feature. It measures the departure of the circular form from an ideal circle, highlighting variations in the surface without considering the alignment of the axis.

To illustrate this distinction, picture a pipe used in industrial settings. Circular cross-sections, when examined for circularity, would assess how closely these sections resemble perfect circles. However, cylindricity evaluation would go further, scrutinizing not just the circularity of these sections but also the alignment and straightness along the entire length of the pipe.

Clarify the blurred lines—grasp the nuances between cylindricity and circularity to ensure comprehensive precision.

The significance of differentiating between cylindricity and circularity emerges in engineering applications. In precision machining, the production of shafts or axles requires not only circular cross-sections but also precise alignment along their entire length. Cylindricity specifications become paramount to ensure that these components not only possess perfect circular sections but also maintain straightness and alignment, ensuring their functionality in various mechanisms.

Moreover, in metrology and quality control, the distinction between cylindricity and circularity guides the selection of measurement techniques and instruments. While circularity might be assessed using profile projectors or optical comparators, evaluating cylindricity demands more sophisticated tools like CMMs (Coordinate Measuring Machines) capable of assessing deviations along multiple axes.

Precision in understanding—grasp the practical implications of distinguishing cylindricity from circularity in engineering applications.

By comprehending these subtle yet crucial distinctions, engineers and manufacturers can articulate precise requirements in blueprints, ensuring that the desired geometric attributes align with the functional necessities of components. Now, let's pivot to explore the methodologies and techniques employed in the meticulous measurement of cylindricity—a pivotal aspect demanding utmost accuracy and precision in assessment.

Measuring cylindricity demands a blend of advanced techniques, specialized tools, and an acute eye for detail. Unlike simple diameter or roundness measurements, evaluating cylindricity involves scrutinizing deviations across multiple axes, ensuring not just the circular form but also the alignment and straightness of the cylindrical feature.

Comprehensive Measurement Techniques

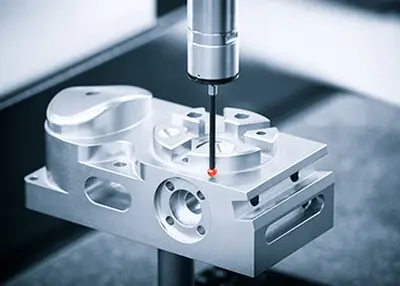

One of the fundamental methods employed in assessing cylindricity involves employing Coordinate Measuring Machines (CMMs). These high-precision instruments meticulously probe the surface of a cylinder, mapping deviations along multiple axes, enabling a comprehensive understanding of its deviations from an ideal form. The data collected through CMMs is then analyzed to derive cylindricity specifications.

Another technique involves the use of dedicated roundness testers or form measurement machines. These instruments assess the deviations from a perfect circle at various points along the length of the cylinder, providing insights into both circularity and alignment.

Challenges in Cylindricity Measurement

However, measuring cylindricity isn't without its challenges. Surface imperfections, material inconsistencies, and environmental factors can significantly impact measurement accuracy. Surface roughness or irregularities might affect probe readings, leading to erroneous evaluations.

Furthermore, the complexity of cylindrical components, especially those with intricate geometries or varying diameters along their length, poses challenges in achieving uniform and precise measurements. Employing advanced measurement strategies, such as utilizing specialized fixtures or adaptive probing techniques, becomes crucial in overcoming these challenges.

Real-world Applications of Cylindricity Measurement

In real-world applications, the precise measurement of cylindricity becomes indispensable. Consider the production of engine crankshafts or precision bearings—components critical to the functioning of automotive or aerospace machinery. Ensuring not just roundness but also alignment and straightness is imperative for these components to function seamlessly within complex assemblies.

Moreover, in medical equipment manufacturing, particularly in prosthetics or orthopedic implants, cylindricity measurements play a crucial role. The precise alignment and roundness of these components ensure their compatibility and functionality within the human body.

Empowerment through Precise Measurement

Understanding and mastering the art of measuring cylindricity empower engineers and manufacturers to set precise tolerances, ensuring that components meet exacting standards. It's not just about achieving a perfect circular form but about guaranteeing the alignment and straightness vital for functionality across diverse applications.

Enhance precision—explore advanced techniques and overcome challenges in measuring cylindricity for flawless engineering.

As we uncover the intricacies of measuring cylindricity, it becomes evident that this process is not just a technical assessment but a gateway to ensuring the reliability, functionality, and precision of critical components across various industries. The journey continues as we explore the impact and relevance of cylindricity in engineering applications.

The influence of cylindricity transcends individual components, shaping the very foundation of engineering designs and functionalities across a myriad of industries.

Consider the aviation industry, where engines act as the heart of aircraft. The alignment and precision of cylindrical components within these engines are paramount. Cylindricity ensures not just circular forms but also the perfect alignment of shafts, pistons, and bearings, safeguarding against potential malfunctions that could have catastrophic consequences.

In automotive engineering, especially in high-performance engines, the pursuit of optimal cylindricity guarantees not only the efficiency of combustion chambers but also the seamless movement of pistons, minimizing friction and enhancing overall performance.

Moving beyond aerospace and automotive, the importance of cylindricity pervades sectors like medical device manufacturing. In the production of prosthetic limbs or joint implants, deviations from ideal cylindrical forms could lead to discomfort, reduced functionality, or even failure. Cylindricity specifications ensure precise alignment and form, offering patients reliability and comfort in their mobility aids.

Moreover, in the realm of semiconductor manufacturing, where precision is paramount at the nanoscale, cylindricity governs the manufacturing of intricate components. The alignment and straightness of cylindrical tools or components used in semiconductor fabrication directly impact the quality and functionality of microelectronics.

Cylindricity isn't just about meeting stringent tolerances; it's also about optimizing designs. In engineering designs, adhering to cylindricity specifications allows for efficient power transmission in gear mechanisms, ensuring smooth operation and minimal energy loss due to misalignments or deviations.

Furthermore, in the production of precision optical equipment, such as telescopes or lenses, cylindricity becomes instrumental in achieving accurate focusing and reducing distortions, ensuring the highest quality of images or vision.

The integration of cylindricity specifications in engineering practices empowers designers and manufacturers to push the boundaries of innovation. It allows them to craft components and systems that not only meet but exceed functional expectations, enabling the creation of cutting-edge technologies that shape our modern world.

Harnessing precision for advancement—embrace cylindricity's impact on reliability, optimization, and design across diverse industries.

By acknowledging the pivotal role of cylindricity in various industries, engineers can optimize designs, enhance functionality, and guarantee reliability. This understanding facilitates the convergence of engineering precision with real-world applications, setting the stage for technological advancements and breakthroughs. Moving forward, let's consolidate our insights and draw conclusions on the significance of cylindricity in engineering excellence.

Cylindricity, often overlooked as a mere geometric attribute, emerges as a cornerstone in the realm of precision engineering. Its multifaceted nature, encompassing not just roundness but also alignment and straightness, renders it indispensable in various engineering domains.

Embracing cylindricity as a fundamental attribute goes beyond the mere attainment of perfect shapes. It signifies a commitment to achieving excellence in engineering. It's the pursuit of not just meeting tolerances but exceeding them to ensure optimal functionality, reliability, and innovation.

In essence, cylindricity acts as a guiding principle, ensuring that cylindrical components, critical to diverse industries, function seamlessly within complex systems. It's the assurance of precision in every aspect—be it aerospace engines, medical implants, or high-tech semiconductor components.

Understanding cylindricity entails navigating through its complexities, decoding its symbols, measuring it with utmost precision, and leveraging its nuances for optimal design and performance. It's the synergy between geometric perfection and real-world functionality.

By embracing cylindricity, engineers and manufacturers uphold a commitment to reliability and efficiency. They empower themselves to translate meticulous blueprints into tangible products, ensuring that each component meets exacting standards and contributes to the advancement of technology.

As technology advances, the demand for precision engineering grows. Cylindricity stands as a testament to this pursuit of perfection—a never-ending journey where each advancement in measurement techniques, manufacturing methodologies, and design innovations further refines the quest for precision.

In conclusion, embracing cylindricity isn't merely about meeting specifications—it's about embracing a mindset that prioritizes precision in every aspect of engineering. It's about unlocking the potential for groundbreaking innovations by ensuring that every cylindrical element embodies not just form but also functionality.

Forge ahead in precision—embrace cylindricity as the bedrock of engineering excellence, shaping the future of technology.

As we culminate this exploration into the realm of cylindricity, it's evident that its significance reverberates across industries, influencing designs, functionalities, and innovations. Embracing cylindricity as a fundamental principle propels us toward a future where precision engineering not only defines but also redefines the boundaries of possibility.

Analysis of the Advantages and Characteristics of 4-axis Machining Center ProcessingOctober 24, 2022At present, there are many methods and equipment used in machining centers, among which CNC four-axis machining centers are a more common machining method. Initially, three-axis machining was generall...view

Analysis of the Advantages and Characteristics of 4-axis Machining Center ProcessingOctober 24, 2022At present, there are many methods and equipment used in machining centers, among which CNC four-axis machining centers are a more common machining method. Initially, three-axis machining was generall...view 6 Reasons Why Choosing a Coastal Processing Supplier Can Make Your Business Better!September 11, 2023If you are an efficient and qualified purchasing staff or boss, you need to read my article, which will break your inherent thinking about supply chain and business management. First, let's think about the following points togetherview

6 Reasons Why Choosing a Coastal Processing Supplier Can Make Your Business Better!September 11, 2023If you are an efficient and qualified purchasing staff or boss, you need to read my article, which will break your inherent thinking about supply chain and business management. First, let's think about the following points togetherview Choosing the Right Finish for Your CNC PartsSeptember 7, 2023From raw CNC machined parts to a final product that gleams with quality involves a crucial decision – selecting the right surface finish or treatment. Choosing the right surface finish or treatment f...view

Choosing the Right Finish for Your CNC PartsSeptember 7, 2023From raw CNC machined parts to a final product that gleams with quality involves a crucial decision – selecting the right surface finish or treatment. Choosing the right surface finish or treatment f...view What Is Zinc Alloy? The Complete Basics to Get StartedOctober 8, 2023This article covers the information you need to watch out for in product design and part manufacturing when using zinc alloy. Take a deeper look into zinc alloy!view

What Is Zinc Alloy? The Complete Basics to Get StartedOctober 8, 2023This article covers the information you need to watch out for in product design and part manufacturing when using zinc alloy. Take a deeper look into zinc alloy!view What Are the Methods of Testing the Properties of Metallic Materials?October 26, 2023Tensile testing is a common method of evaluating the strength and ductility of materials. It involves placing a specimen in a tensile testing machine, gradually applying a tensile force, measuring the stress-strain curve and determining the yield strength, tensile strength, and elongation of the material.view

What Are the Methods of Testing the Properties of Metallic Materials?October 26, 2023Tensile testing is a common method of evaluating the strength and ductility of materials. It involves placing a specimen in a tensile testing machine, gradually applying a tensile force, measuring the stress-strain curve and determining the yield strength, tensile strength, and elongation of the material.view What Is Mechanical Rack: Picking the Best for Your Custom PartsMay 22, 2024Delve into the world of equipment racks with this comprehensive article. Learn about their structure, design principles, materials, manufacturing processes, installation, commissioning, and more.view

What Is Mechanical Rack: Picking the Best for Your Custom PartsMay 22, 2024Delve into the world of equipment racks with this comprehensive article. Learn about their structure, design principles, materials, manufacturing processes, installation, commissioning, and more.view