Whether you're an entrepreneur seeking rapid prototyping or a hobbyist looking to bring your creative ideas to life, 3D printing service offers a world of possibilities. However, have you ever thought about the cost of 3D printing, and how to obtain and achieve a cheap 3D printing service?

The 3D printing process revolves around crafting three-dimensional items from digital blueprints, one layer at a time. The printer constructs these layers using materials like plastic filaments or resins, ultimately producing tangible and intricately detailed objects.

Due to the hidden costs, technical barriers, and the diverse combinations of materials and printing methods associated with 3D printing, some platforms have introduced 3D printing services to meet such demands. These 3D printing service providers aim to offer more cost-effective and tailored solutions to those with 3D printing needs.

3D printing service serves as an adaptable and multifaceted platform that empowers both individuals and enterprises to transform their digital designs into tangible, three-dimensional objects of astounding intricacy and functionality. It allows you to order custom 3D printed parts online from a network of 3D printing providers. You can upload your 3D model, choose the 3D printing technology, material, and finish, and get an instant quote and delivery time.

The cost of a 3D printing service is influenced by a multitude of factors, each of which can significantly impact your budget.

Your choice of material is the foundational determinant of your 3D printing cost. Common materials include plastics, metals, ceramics, resins, and more.

Plastics: PLA and ABS plastics are often the most budget-friendly options. They're widely used for prototypes and consumer products.

Resins: Resin-based 3D printing provides exceptional detail and surface finish, but it tends to be more expensive than traditional filament-based printing.

Metals: Printing with metals, such as aluminum, stainless steel, or titanium, is usually more expensive due to the high cost of the raw materials and the advanced printing technology required.

Ceramics: Ceramics offer unique properties like heat resistance and electrical insulation, but they can be on the higher end of the cost spectrum.

Intricate and highly detailed designs can demand more time and resources to print accurately.

Geometric Complexity: Models with intricate geometric shapes, overhangs, or fine details may require additional time and support structures, increasing print time and cost.

Size: Larger models often consume more material and may require specialized equipment, resulting in higher costs.

Support Structures: Complex designs may necessitate the use of support structures, which can increase material usage and post-processing time.

Ordering multiple copies of the same model can lead to significant cost savings per unit.

Urgent orders often come with expedited processing fees. If time is of the essence, you may need to pay a premium to prioritize your project in the printing queue.

Many 3D printing service providers offer a range of post-processing services including painting, assembly, sanding, or other finishing touches.

Simplifying intricate details or optimizing your model's structure can help manage costs without sacrificing quality.

Hollowing out your 3D model is a clever technique to reduce the amount of material used without compromising the structural integrity of the final product. By creating voids or empty spaces within the design, you significantly decrease the overall material consumption, subsequently lowering the 3D print cost.

Another strategy for optimizing affordability is to adjust the size of your 3D model to fit efficiently within the printing volume. Scaling can have a direct impact on both material usage and printing time, allowing you to save on costs without compromising the result.

Simplifying complex designs is another effective approach to reducing both printing time and material requirements. While intricate and detailed designs can be captivating, they often demand more resources, which can drive up costs. Streamlining your 3D model involves reducing unnecessary details or intricate features that may not significantly impact the design's overall appearance or functionality.

Some of the common types of materials used for 3D printing are plastics, metals, ceramics, and resins (for more details please refer to section "Material Selection" above). Different materials have different prices and strength, flexibility, heat resistance, or biocompatibility that suit different purposes and applications.

For instance, plastics are the most widely used materials for 3D printing, as they are cheap, easy to print, and versatile. Metals offer high strength, durability, and conductivity. However, it comes at a higher cost.

Opting for the cheapest 3D printing service provider won't guarantee a smooth experience. If collaboration with a 3D printing service provider is not smooth, repeated trial and error can result in time wastage. The continuous trial and error can also lead to material wastage and increased costs. Therefore, choosing the right 3D printing service provider directly impacts the cost of the 3D printing project.

As you consider the ideal provider for your needs, it's important to take various aspects into account.

1. Range of Technologies and Materials

A fundamental consideration when choosing a 3D printing service provider is the range of technologies and materials they offer. Richconn excels in this regard, providing a diverse array of 3D printing technologies and materials to accommodate a wide spectrum of projects. Whether you require metal parts with exceptional strength and durability through processes like Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS), or you're working with other materials, Richconn has you covered.

2. Quality and Accuracy

Richconn's stringent quality control measures and rigorous testing protocols ensure that every product meets the highest industry standards. This prevents deviations from specifications or unexpected results, thus avoiding wasted time and resources.

3. Speed and Reliability

Timely completion of your 3D printing project is often crucial. Richconn recognizes the significance of meeting your deadlines and budget constraints. Our streamlined processes and efficient production workflows ensure that your 3D printing orders are fulfilled within your specified timeframe and budget.

4. Competitive Pricing and Value

Richconn is committed to offering competitive and reasonable pricing for your 3D printing projects, ensuring that you receive exceptional value for your investment. By comparing various 3D printing service providers based on factors such as price, quality, speed, and customer satisfaction, you'll find that Richconn consistently stands out as a top choice for obtaining the best value for your money.

Bring your 3D printing projects to life!

Explore our custom 3D printing services today >>>

Understanding the intricacies of 3D printing service costs, optimizing for affordability through strategies like hollowing and scaling, and selecting the right materials are essential steps toward achieving cost-effective yet high-quality results. Furthermore, the choice of a reliable 3D printing service provider can significantly impact the success of your project. With a wide range of technologies and materials, stringent quality control measures, efficient production processes, and competitive pricing, Richconn emerges as a trusted partner in turning your 3D printing visions into reality, all while managing costs effectively.

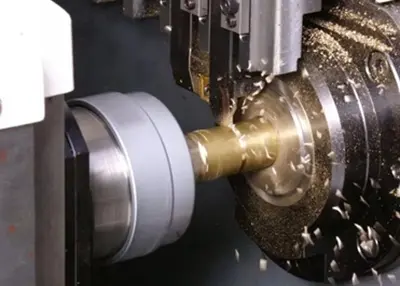

What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view

What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view From Start-up to Llarge ManufacturerOctober 10, 2023As a manufacturing startup, your success story starts with proving that your product is marketable. When you prepare for large-scale production, it determines the success or failure of the company, because it is in this situation that you have to invest a lot of money and determine the future direction.view

From Start-up to Llarge ManufacturerOctober 10, 2023As a manufacturing startup, your success story starts with proving that your product is marketable. When you prepare for large-scale production, it determines the success or failure of the company, because it is in this situation that you have to invest a lot of money and determine the future direction.view How many types of cast iron are there? How are the grades represented? The various uses of cast iron?October 31, 2023Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains mangan...view

How many types of cast iron are there? How are the grades represented? The various uses of cast iron?October 31, 2023Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains mangan...view Which Is Easier to Weld, Aluminum or Stainless Steel?October 26, 2023This is because the melting point of stainless steel is higher than that of aluminum alloys, which makes it more stable during the welding process. Aluminum alloys are prone to the risk of being burned through because of their low melting point during the welding process. In addition, aluminum alloys are also susceptible to the formation of an aluminum oxide film on the surface in air, which has a much higher melting point than aluminum itself, making it more difficult to weld.view

Which Is Easier to Weld, Aluminum or Stainless Steel?October 26, 2023This is because the melting point of stainless steel is higher than that of aluminum alloys, which makes it more stable during the welding process. Aluminum alloys are prone to the risk of being burned through because of their low melting point during the welding process. In addition, aluminum alloys are also susceptible to the formation of an aluminum oxide film on the surface in air, which has a much higher melting point than aluminum itself, making it more difficult to weld.view Super-material carbon fiber: raw material production and its application and processingDecember 20, 2023Carbon fiber materials are used more and more widely, and their manufacturing is correspondingly accepted by more people. Price, capability and quality are all our advantages.view

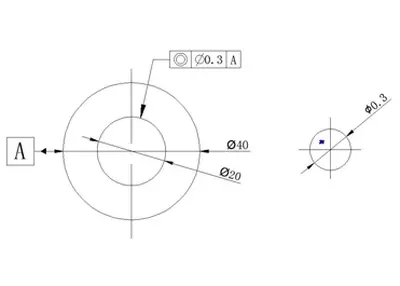

Super-material carbon fiber: raw material production and its application and processingDecember 20, 2023Carbon fiber materials are used more and more widely, and their manufacturing is correspondingly accepted by more people. Price, capability and quality are all our advantages.view Positioning control - concentricity/coaxialityNovember 17, 2023When manufacturing cylindrical CNC milled parts, concentricity is the unit of measure of part accuracy. Concentricity, is the degree to which the inner diameter of the insert is offset from the center of the entire circle.view

Positioning control - concentricity/coaxialityNovember 17, 2023When manufacturing cylindrical CNC milled parts, concentricity is the unit of measure of part accuracy. Concentricity, is the degree to which the inner diameter of the insert is offset from the center of the entire circle.view

EN

EN

ru

ru