Anodized aluminum is a metal with widespread use and advantages. It is a process of treating metal with electricity to create an oxide protective layer on the surface. This layer helps to protect aluminum from corrosion and wear, making it an excellent choice for outdoor applications. Anodized aluminum can also resist scratches, dents, and other forms of physical damage.

Anodized aluminum is a sturdy and durable material that is resistant to corrosion and wear. This makes it an excellent choice for outdoor applications such as patio furniture, window frames, and garage doors. It is also known for its resistance to scratches, dents, and other forms of physical damage, making it an excellent choice for items that may be frequently handled. Anodized aluminum is also aesthetically pleasing as it is available in multiple colors and finishes.

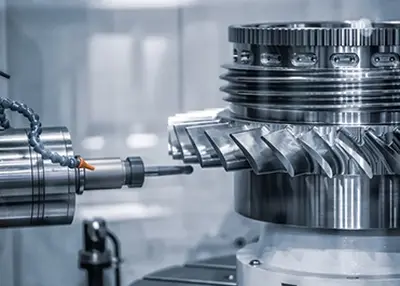

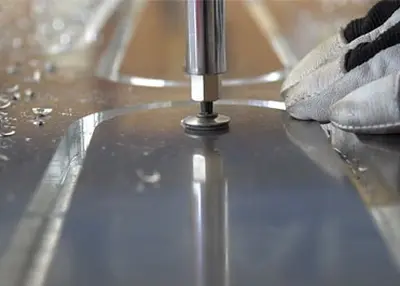

Another advantage of anodized aluminum is its low maintenance requirements. Unlike other CNC machining materials, it does not need to be cleaned or polished regularly. This makes it an ideal choice for areas that are impossible or do not require frequent cleaning. Additionally, anodized aluminum has a high resistance to extreme temperatures, making it suitable for environments that may experience temperature fluctuations.

Anodized aluminum is a widely used material that can be utilized in a variety of applications. It is commonly used in the automotive and aerospace industries, where its strength and durability make it an ideal choice for parts that must withstand extreme temperatures and conditions. Natural anodized aluminum is also used in the construction of buildings and other structures, where its low maintenance requirement makes it an excellent choice for exterior surfaces.

In addition to its strength and durability, anodized aluminum is also known for its aesthetic qualities. It is available in a variety of colors and finishes, allowing for easy customization and matching of any space's color scheme. This makes it an ideal choice for interior design projects such as kitchen cabinets, furniture, and wall panels. Anodized aluminum can also be used to create decorative pieces, such as sculptures and art pieces.

Anodized aluminum is a relatively affordable material, making it an attractive choice for many projects. It is typically less expensive than other metals such as stainless steel and titanium, making it an excellent choice for people on a limited budget. Anodized aluminum is also easy to work with, making it a good choice for DIY projects.

Anodized aluminum is a sturdy and durable material that is resistant to corrosion and wear. It is also aesthetically pleasing and available in multiple colors and finishes. Additionally, its low maintenance requirements make it an ideal choice for areas that are impossible or do not require frequent cleaning. Anodized aluminum is also a widely used material that can be utilized in a variety of applications, from automotive and aerospace parts to decorative pieces. Finally, it is an affordable and easy-to-work-with material that is an excellent choice for DIY projects.

As a pro China CNC machining factory, Richconn can provide you with quality OEM precision CNC machining with anodized aluminum material. Feel free to contact for further info and help!

The Top 7 CAD/CAM Software for CNC ProjectsMarch 18, 2024CAD/CAM software for CNC projects is a specialized tool used to design and control the machining of parts. Here are the top 7 CAD/CAM software for your choice.view

The Top 7 CAD/CAM Software for CNC ProjectsMarch 18, 2024CAD/CAM software for CNC projects is a specialized tool used to design and control the machining of parts. Here are the top 7 CAD/CAM software for your choice.view CNC Machining and AI: How Artificial Intelligence is Impacting the FieldOctober 25, 2023Artificial Intelligence is having a profound impact on CNC machining services, transforming operations and delivering many benefits. Here are some of the key areas where AI is playing a major role:view

CNC Machining and AI: How Artificial Intelligence is Impacting the FieldOctober 25, 2023Artificial Intelligence is having a profound impact on CNC machining services, transforming operations and delivering many benefits. Here are some of the key areas where AI is playing a major role:view Cast Aluminum vs Machined Aluminum: Unveiling the Crafting MarvelsNovember 13, 2023In the realm of metal fabrication, the choice between cast aluminum and machined aluminum holds the key to unlocking a world of possibilities. As a CNC machining service provider, we, at Richconn, understand the importance of making informed decisions in the manufacturing process. Let's embark on a journey to explore the nuances of these two techniques, dissecting their processes, comparing their performance, and uncovering their diverse applications.view

Cast Aluminum vs Machined Aluminum: Unveiling the Crafting MarvelsNovember 13, 2023In the realm of metal fabrication, the choice between cast aluminum and machined aluminum holds the key to unlocking a world of possibilities. As a CNC machining service provider, we, at Richconn, understand the importance of making informed decisions in the manufacturing process. Let's embark on a journey to explore the nuances of these two techniques, dissecting their processes, comparing their performance, and uncovering their diverse applications.view From Start-up to Llarge ManufacturerOctober 10, 2023As a manufacturing startup, your success story starts with proving that your product is marketable. When you prepare for large-scale production, it determines the success or failure of the company, because it is in this situation that you have to invest a lot of money and determine the future direction.view

From Start-up to Llarge ManufacturerOctober 10, 2023As a manufacturing startup, your success story starts with proving that your product is marketable. When you prepare for large-scale production, it determines the success or failure of the company, because it is in this situation that you have to invest a lot of money and determine the future direction.view CNC numerical control cutting aluminum sheet, the efficient tool of modern manufacturingAugust 4, 2023In modern manufacturing, aluminum sheets are widely used, and CNC (Computer Numerical Control) cutting technology has become an efficient tool for processing aluminum sheets. CNC cutting aluminum she...view

CNC numerical control cutting aluminum sheet, the efficient tool of modern manufacturingAugust 4, 2023In modern manufacturing, aluminum sheets are widely used, and CNC (Computer Numerical Control) cutting technology has become an efficient tool for processing aluminum sheets. CNC cutting aluminum she...view What is a CNC Machine?October 20, 2023The full name of CNC is Computer Numerical Control, and a tooling machine with a computer as the control center is called a CNC machine. The traditional tooling machines need to be manually operated to achieve a variety of metal processing techniques, CNC machine is by the engineers of the computer input product drawings, complete the product required tooling sequence, processing environment parameters and other data, by the computer according to the above instructions for automated production.view

What is a CNC Machine?October 20, 2023The full name of CNC is Computer Numerical Control, and a tooling machine with a computer as the control center is called a CNC machine. The traditional tooling machines need to be manually operated to achieve a variety of metal processing techniques, CNC machine is by the engineers of the computer input product drawings, complete the product required tooling sequence, processing environment parameters and other data, by the computer according to the above instructions for automated production.view

EN

EN

ru

ru