Are you seeking the perfect material for your CNC machining project, one that promises precision and durability? Look no further than CNC steel. In this guide, I'll take you through the world of CNC steel, helping you understand its various types, selection criteria, and how to make the most of this essential material in your CNC machining endeavors.

CNC steel, short for Computer Numerical Control steel, plays a pivotal role in the realm of CNC machining. It's a versatile material known for its strength, durability, and malleability. When you're looking to create precise, custom components or intricate parts, CNC steel should be at the top of your material list.

To get started, let's dive into the world of CNC steel:

Stainless Steel: Renowned for its corrosion resistance, stainless steel is the go-to material for applications requiring hygiene and longevity. From medical equipment to kitchen appliances, it's the material of choice for a reason.

High Carbon Steel: If you need strength and hardness in your components, high carbon steel is your solution. It's perfect for cutting tools and high-wear applications.

Aluminum Alloys: Seeking a lightweight but durable option? Aluminum alloys are ideal for CNC machining projects where weight matters, such as aerospace and automotive parts.

Alloy Steel: For applications demanding a combination of strength, toughness, and wear resistance, alloy steel is the answer. It's widely used in engineering and industrial applications.

Selecting the right CNC steel for your project is crucial. It directly impacts the outcome and the efficiency of the CNC machining process.

Project Requirements: Start by understanding your project's specific needs. What are the environmental conditions, load-bearing requirements, and expected longevity? These factors will guide your material choice.

Material Properties: Each type of CNC steel comes with distinct properties. Consider factors like hardness, tensile strength, and resistance to corrosion when choosing the material.

Material Compatibility: Ensure that the chosen CNC steel is compatible with your CNC machining equipment. Different materials may require specific tooling and settings.

Practical Example: To illustrate the material selection process, let's consider a scenario. You're working on a project that involves a component for a marine application, and corrosion resistance is crucial. In this case, stainless steel would be the optimal choice.

Understanding the CNC machining process is essential for achieving the desired results. Here's an overview:

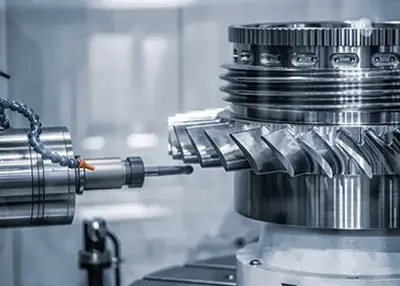

CNC Basics: Familiarize yourself with the fundamentals of CNC machining. This technology uses computer-controlled machines to precisely cut, shape, and fabricate components.

Steel in CNC Machining: Steel's malleability and strength make it a favorable choice in CNC machining. It can be precisely cut, shaped, and formed into intricate parts with minimal wastage.

Programming and Control Systems: CNC machining relies on programming and control systems to execute precise movements and operations. This ensures the material is cut and shaped according to design specifications.

Cutting Tools and Techniques: The choice of cutting tools, such as end mills and drills, is crucial. Each tool serves a specific purpose, so understanding the right tool for the job is essential.

For a deeper understanding, let's look at some data related to CNC steel machining:

| CNC Steel Type | Tensile Strength (MPa) | Hardness (HRC) | Common Applications |

|---|---|---|---|

| Stainless Steel | 600-1000 | 20-60 | Medical devices, kitchen equipment, aerospace components |

| High Carbon Steel | 700-1400 | 60-65 | Cutting tools, industrial equipment |

| Aluminum Alloys | 200-500 | 30-70 | Aerospace components, automotive parts |

| Alloy Steel | 800-1200 | 50-70 | Machinery components, structural parts |

This table provides a quick reference for the tensile strength, hardness, and common applications of various CNC steel types. It's a valuable resource for material selection.

Quality is paramount in CNC machining, and Richconn understands the significance of delivering precision and reliability. Using high-quality CNC steel ensures your final components meet your expectations and the expectations of your customers. Here's how you can ensure the highest quality standards in your CNC steel and machining processes:

Before diving into the details of CNC steel quality assurance, it's essential to understand the industry's quality standards. These standards serve as benchmarks for material performance and reliability. Richconn adheres to these standards to guarantee exceptional results.

To maintain the highest quality standards, partnering with trustworthy CNC steel suppliers is of the utmost importance. Richconn collaborates with suppliers who share our commitment to quality. These suppliers provide certifications and guarantees, offering transparency and peace of mind.

Ensuring CNC steel quality begins with a thorough quality inspection process. This process involves rigorous testing and inspections of the CNC steel to verify its compliance with quality standards.

Material testing is a critical component of quality inspection. Richconn conducts tests to assess the material's properties, including tensile strength, hardness, and resistance to corrosion. These tests confirm that the CNC steel meets or exceeds industry requirements.

Detailed inspections are carried out to identify any imperfections, defects, or inconsistencies in the CNC steel. This meticulous approach ensures that only high-quality materials proceed to the CNC machining stage.

To illustrate the impact of a rigorous quality assurance process, let's explore a success story. Richconn recently completed a project involving precision components for the aerospace industry. The strict adherence to quality standards, material testing, and thorough inspections led to components that exceeded the aerospace industry's stringent requirements. This project highlights our dedication to delivering excellence.

Richconn's commitment extends to meeting diverse customer demands and delivering exceptional results. CNC machining is a versatile process that can be tailored to a wide range of projects and individual customer requirements.

We acknowledge the variety of projects and demands encountered as a CNC machining service provider. Our expertise covers an array of industries, from aerospace and automotive to healthcare and consumer electronics.

Richconn offers customized CNC machining services to cater to individual project requirements. Tailoring the process, tooling, and material selection to match the project's unique demands ensures that our customers receive precisely what they need.

Quality is the cornerstone of Richconn's CNC machining services. Meticulous attention to detail, precision tooling, and a commitment to excellence ensure that every project we undertake meets or exceeds industry standards.

Let's delve into a case study that showcases our ability to meet a customer's unique demands. Recently, Richconn worked on a project involving the production of custom automotive components. The project required a specific aluminum alloy, and our team's expertise in material selection, CNC machining, and quality assurance resulted in components that met the highest industry standards.

Richconn is dedicated to delivering quality CNC steel and machining services that meet and exceed customer expectations. Our commitment to quality standards, reliable suppliers, rigorous material testing, and custom CNC machining solutions ensures that your projects are in capable hands. With a track record of success, we look forward to collaborating with you to achieve your CNC machining goals. Your journey into the world of CNC steel is guided by precision, reliability, and excellence—qualities that define Richconn's CNC machining services.

As a precision machine shop, Richconn understands that our role extends beyond the production phase. We are committed to supporting our clients throughout their CNC steel and machining journey. Here's how Richconn provides comprehensive support to our valued customers:

At Richconn, we believe in empowering our customers with knowledge and expertise. We offer technical consultation and support to guide you through the complexities of CNC steel selection and machining processes.

Choosing the right CNC steel can be a challenging task. Our technical experts are ready to assist you in making informed decisions. We consider your project's specific requirements and advise you on the most suitable CNC steel for your needs.

Designing parts for CNC machining requires precision and attention to detail. Our team can provide guidance on optimizing your designs for CNC steel machining, ensuring efficient production and cost-effectiveness.

Curious about the feasibility of your CNC machining project? Our technical team can assess your project's viability, considering factors such as material selection, machining processes, and budget constraints.

Understanding the advantages of CNC machining is essential for making informed decisions about your projects. Richconn is dedicated to educating our clients on the benefits of CNC machining:

CNC machining guarantees precision and repeatability in every part produced. The computer-controlled machines execute operations with exceptional accuracy, ensuring consistent results for your components.

The flexibility of CNC machining allows for the production of complex and intricate shapes. Richconn's state-of-the-art CNC equipment can create custom components that meet your exact design specifications.

CNC machining offers high productivity and efficiency. With minimal manual intervention, the process is faster and more cost-effective compared to traditional machining methods.

Meeting deadlines and providing excellent customer support are integral to Richconn's customer-centric approach. We understand that timely delivery and responsive customer service are vital for your projects' success.

We prioritize on-time delivery of projects. Our streamlined CNC machining processes, experienced team, and efficient project management ensure that your components are delivered according to schedule.

At Richconn, we value open communication and prompt responses to customer inquiries. Our customer support team is readily available to address your queries, concerns, and requests.

Our commitment doesn't end with project completion. We offer comprehensive after-sales service to ensure the long-term satisfaction of our customers. If any issues or questions arise after project delivery, we are here to assist.

Challenges can arise during CNC steel selection and machining processes. At Richconn, we have a proven track record of problem-solving and overcoming obstacles to deliver successful results.

Let's explore real-life examples of problem-solving in CNC machining. From unexpected material shortages to design modifications, our team's adaptability and problem-solving skills have ensured project success.

Richconn is not just a CNC machining service provider; we are your partner in achieving excellence. We offer technical consultation, educate you on the advantages of CNC machining, prioritize on-time delivery, and provide exceptional customer support. Our commitment to problem-solving and after-sales service is unwavering. Richconn is dedicated to your success, and we look forward to collaborating with you on your CNC steel and machining projects. Your journey to precision, efficiency, and reliability begins with Richconn.

How to DIY CNC Machine?November 2, 2023Are you ready to unlock the world of CNC machining from the comfort of your own workshop? In this article, I will guide you through the process of creating your very own DIY CNC machine, step by step. Whether you're a seasoned DIY enthusiast or just starting out, this article will equip you with the knowledge and skills you need to build, operate, and maintain your CNC machine.view

How to DIY CNC Machine?November 2, 2023Are you ready to unlock the world of CNC machining from the comfort of your own workshop? In this article, I will guide you through the process of creating your very own DIY CNC machine, step by step. Whether you're a seasoned DIY enthusiast or just starting out, this article will equip you with the knowledge and skills you need to build, operate, and maintain your CNC machine.view Laser Etching: Guide and Comprehensive ContentOctober 8, 2023Laser Etching is a high-precision processing technique widely used to create fine patterns, markings, and engravings on a variety of materials. It utilizes the high energy of a laser beam to gradually remove the surface of a material to create depth, patterns or text.view

Laser Etching: Guide and Comprehensive ContentOctober 8, 2023Laser Etching is a high-precision processing technique widely used to create fine patterns, markings, and engravings on a variety of materials. It utilizes the high energy of a laser beam to gradually remove the surface of a material to create depth, patterns or text.view What is CNC Milling Machine: Definition, Uses, Types & PricesMarch 29, 2024Let's delve deeper into CNC milling machine, which holds significant importance for your project, and explore the mill machine in detail.view

What is CNC Milling Machine: Definition, Uses, Types & PricesMarch 29, 2024Let's delve deeper into CNC milling machine, which holds significant importance for your project, and explore the mill machine in detail.view Excellent Corrosion Resistance of Stainless Steel-316L Stainless SteelOctober 24, 2023Dear viewers, today we are going to talk about an amazing material - 316L stainless steel. Did you know? This ordinary-looking material has amazing corrosion resistance! 316L stainless steel as a low carbon series of 316 steel, in addition to the same characteristics with 316 steel, its resistance to grain boundary corrosion is excellent, let's take a look at it!view

Excellent Corrosion Resistance of Stainless Steel-316L Stainless SteelOctober 24, 2023Dear viewers, today we are going to talk about an amazing material - 316L stainless steel. Did you know? This ordinary-looking material has amazing corrosion resistance! 316L stainless steel as a low carbon series of 316 steel, in addition to the same characteristics with 316 steel, its resistance to grain boundary corrosion is excellent, let's take a look at it!view What are the machining processes?November 16, 2023Machining processes are a key manufacturing method used to transform raw materials into desired parts and products. These processes include milling, turning, drilling, grinding, reaming, stamping, forging, injection molding, EDM, heat treatment, welding, stretch molding, powder metallurgy and 3D printing. The following are some common machining processes:view

What are the machining processes?November 16, 2023Machining processes are a key manufacturing method used to transform raw materials into desired parts and products. These processes include milling, turning, drilling, grinding, reaming, stamping, forging, injection molding, EDM, heat treatment, welding, stretch molding, powder metallurgy and 3D printing. The following are some common machining processes:view Understanding the Magic of Electrophoresis PlatingJanuary 5, 2024Electrophoresis plating is a fascinating technique that plays a crucial role in several industries. It is a process that involves the deposition of a metallic coating onto a conductive surface through...view

Understanding the Magic of Electrophoresis PlatingJanuary 5, 2024Electrophoresis plating is a fascinating technique that plays a crucial role in several industries. It is a process that involves the deposition of a metallic coating onto a conductive surface through...view