Are you ready to unlock the world of CNC machining from the comfort of your own workshop? In this article, I will guide you through the process of creating your very own DIY CNC machine, step by step. Whether you're a seasoned DIY enthusiast or just starting out, this article will equip you with the knowledge and skills you need to build, operate, and maintain your CNC machine.

I. Understanding DIY CNC Machines

What is a DIY CNC machine?

The incredible range of DIY CNC applications

II. The Art of Precision Machining

How CNC machines bring precision to your projects

The limitless possibilities of CNC machining

In this section, we'll delve into the world of DIY CNC machines, exploring what they are and the wide array of applications they offer. Additionally, we'll introduce Richconn, a leading CNC machining service provider based in China.

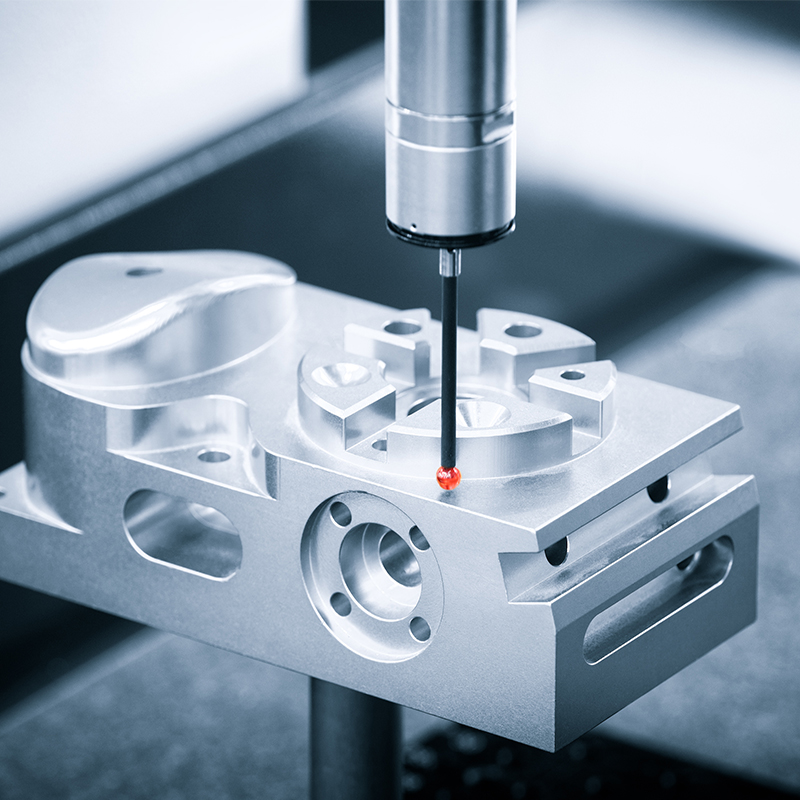

DIY CNC machines, or Do-It-Yourself Computer Numerical Control machines, are versatile tools that allow you to automate various machining tasks with precision. These machines combine hardware and software, enabling you to create intricate designs, cut materials with high accuracy, and bring your creative ideas to life. Richconn, a prominent Chinese precision machine shop, is known for producing state-of-the-art CNC machines and providing comprehensive solutions to a global customer base.

Table 1: Advantages of DIY CNC Machines

| Advantages | Description |

|---|---|

| Precision Machining | Achieve high levels of precision in your projects. |

| Versatile Applications | Use CNC machines for engraving, cutting, milling, and more. |

| Customization Options | Adapt your DIY CNC machine to suit your specific needs. |

| Cost-Effective Solutions | DIY CNC machines offer cost savings compared to commercial alternatives. |

| Learning and Creativity | Learn the intricacies of CNC machining and unleash your creativity. |

CNC machines are revered for their ability to bring unprecedented precision to your projects. Whether you're a hobbyist or a professional, the precision offered by CNC machines is a game-changer. Richconn, as a leading CNC machining service provider, embodies this precision in the services it offers.

Table 2: Richconn - Your Precision CNC Partner

| Services Offered | Description |

|---|---|

| CNC Machining Services | Richconn offers a wide range of CNC machining services. |

| Advanced Technology | Utilize cutting-edge CNC technology for your projects. |

| Quality and Reliability | Depend on Richconn for high-quality, reliable results. |

| Custom Solutions | Get tailored CNC solutions to meet your specific needs. |

CNC Machine Basics

The fundamental principles behind CNC machines

How CNC technology revolutionized manufacturing

The Role of Control Systems and Motors

Unveiling the power of control systems

Understanding the motors' contribution to CNC precision

In this section, we'll explore the fundamental principles behind CNC machines, including how they operate and the essential components that make them work seamlessly.

CNC machines operate based on the principles of computer numerical control, allowing for precise, automated control of machining processes. These machines have transformed industries by enabling the production of complex, highly accurate components and products. Understanding the core principles of CNC is crucial for those embarking on a DIY CNC machine project.

Table 3: Key CNC Machine Principles

| Principle | Description |

|---|---|

| Computer Numerical Control | CNC machines are controlled by computer programs and code. |

| Automation | CNC machines automate processes, reducing manual labor. |

| Precision | Achieve high levels of precision and accuracy in machining. |

| Versatility | CNC machines are versatile, suitable for various applications. |

| Repetition | Consistent results are achieved in large-scale production. |

At the heart of every CNC machine are the control systems and motors that drive its movements. These components work in unison to execute precise toolpath instructions.

Table 4: Control Systems and Motors in CNC Machines

| Component | Function in CNC Machines |

|---|---|

| Control Systems | Interpret and execute CNC code to control machine movements. |

| Motors | Power the movement of machine components, like the cutter. |

| Precision and Accuracy | Ensure high precision and accuracy in machining operations. |

| Real-time Adjustments | Allow for on-the-fly adjustments to machining parameters. |

Richconn, as a reputable CNC machining service provider, relies on advanced control systems and high-performance motors to deliver precision and accuracy in their machining services.

Table 5: Richconn's Cutting-Edge Technology

| Cutting-Edge Technology | Description |

|---|---|

| Advanced Control Systems | Utilizes the latest control technology. |

| High-Performance Motors | Ensures precise and efficient machining. |

| Precision Engineering | Adheres to strict quality and precision standards. |

By understanding these principles and the role of control systems and motors, you'll be better equipped to design, build, and operate your DIY CNC machine effectively.

Essential Tools and Equipment

Building your toolkit for CNC machine assembly

Must-have tools for the DIY enthusiast

Creating Your Materials Checklist

Selecting materials for your DIY CNC project

Recommended suppliers and sources for CNC components

In this section, we'll delve into the crucial preparation phase for your DIY CNC machine project. We'll discuss the essential tools and equipment required, as well as creating a materials checklist for your project.

Before you embark on the journey of building your DIY CNC machine, it's essential to equip yourself with the right tools and equipment. These tools will be your trusted companions throughout the assembly process, ensuring that your machine is constructed with precision and care.

Table 6: Essential Tools for DIY CNC Machine Assembly

| Tool | Description |

|---|---|

| Screwdrivers | Used for securing components and connections. |

| Wrenches | Necessary for tightening bolts and nuts. |

| Pliers | Ideal for gripping and maneuvering small parts. |

| Calipers | Ensure precise measurements during assembly. |

| Allen Wrenches | Essential for hexagonal socket screws. |

| Level | Maintain the machine's balance and alignment. |

| Safety Gear | Protect yourself with gloves and safety glasses. |

Richconn, as a leading CNC machining service provider, is well-equipped with an array of professional tools and equipment, ensuring precise and efficient machining.

Table 7: Richconn's Professional Tools

| Professional Tools | Description |

|---|---|

| Specialized CNC Tools | Utilizes a wide range of CNC-specific tools. |

| Safety Equipment | Prioritizes safety with protective gear. |

| Quality Control Measures | Implements rigorous quality control standards. |

| Skilled Workforce | Employs skilled professionals for precision. |

Selecting the right materials for your DIY CNC machine is a critical step in ensuring the longevity and functionality of your project. It's important to source materials from reputable suppliers, such as Richconn, to guarantee the quality and performance of your CNC components.

Table 8: Materials Checklist for DIY CNC Machine

| Component | Description |

|---|---|

| Frame and Base Materials | Determine the structure and rigidity. |

| Motion System Components | Include rails, ball screws, and guides. |

| Control System Hardware | Choose controllers, drivers, and interfaces. |

| Cutting Tools | Select end mills, drills, or other cutters. |

| Electronics and Wiring | Incorporate motors, sensors, and wiring. |

Table 9: Richconn - Your Trusted CNC Material Supplier

| Material Services | Description |

|---|---|

| High-Quality Materials | Provides top-tier materials for CNC machine construction. |

| Expert Consultation | Offers expert guidance in selecting the right materials. |

| Global Material Sourcing Network | Access to a vast network of reliable material suppliers. |

| Quality Assurance | Ensures the materials meet strict quality standards. |

By preparing with the right tools and materials, you'll set a solid foundation for your DIY CNC machine project.

Assembling the Frame and Base

The foundation of your DIY CNC machine

Guidelines for a sturdy and reliable base

Installing Motors and Rails

The heart of motion control

Precision rail installation for smooth operation

Connecting the Control System

Linking the brains of your CNC machine

Configuring your control system for optimal performance

Mounting Cutting Tools

Adding the finishing touch to your CNC machine

Selection and installation of cutting tools

In this section, we'll guide you through the assembly process of your DIY CNC machine. We'll cover the foundation, the installation of crucial components, and the final steps that bring your CNC machine to life.

The foundation of your DIY CNC machine is crucial for its stability and precision. Let's explore the steps required to assemble a sturdy and reliable base for your project.

Table 10: Assembling the CNC Machine Base

| Assembly Steps | Description |

|---|---|

| Frame Selection and Setup | Choose the right frame materials and configure the frame structure. |

| Base and Supports Installation | Secure the base and supports for stability. |

| Leveling and Alignment | Ensure the base is level and aligned correctly. |

| Frame Stiffening and Bracing | Add reinforcements for improved rigidity. |

The heart of motion control in your CNC machine lies within the motors and rails. The precise installation of these components is vital for achieving smooth and accurate machine movements.

Table 11: Motor and Rail Installation

| Installation Steps | Description |

|---|---|

| Motor Mounting and Alignment | Secure motors to the frame and align them properly. |

| Rail Installation and Calibration | Attach rails and ensure they are perfectly aligned. |

| Wiring and Connection | Connect motors to the control system and power source. |

| Testing and Fine-Tuning | Test motion and fine-tune settings for smooth operation. |

Your CNC machine's control system is the brain behind its operation. It interprets CNC code and directs the motors to create your desired output. Let's explore the process of connecting and configuring the control system.

Table 12: Control System Connection

| Connection Steps | Description |

|---|---|

| Controller and Driver Setup | Configure the controller and drivers for your system. |

| Wiring and Electronics Setup | Connect sensors, motors, and power sources to the control system. |

| Software Installation | Install and configure the necessary CNC control software. |

| Calibration and Testing | Calibrate the system and run test movements. |

The final step in assembling your DIY CNC machine is the installation of cutting tools. This step brings your machine to life, allowing you to begin creating your projects.

Table 13: Cutting Tool Mounting

| Installation Steps | Description |

|---|---|

| Tool Selection | Choose the appropriate cutting tools for your projects. |

| Tool Holder and Setup | Secure the cutting tool in the tool holder. |

| Tool Alignment and Testing | Ensure proper alignment and conduct test cuts. |

| Safety Precautions | Implement safety measures when handling cutting tools. |

By following these assembly steps carefully, you'll be well on your way to having a functional DIY CNC machine ready for your projects.

Daily Maintenance Routine

Keeping your DIY CNC machine in top shape

Best practices for routine maintenance

Troubleshooting and Problem-Solving

Common issues and how to resolve them

Troubleshooting guide for CNC enthusiasts

Extending the Lifespan

Prolonging the life of your DIY CNC machine

Tips for longevity and efficiency

In this section, we'll explore the vital aspects of maintaining and caring for your DIY CNC machine. Regular maintenance and effective troubleshooting are essential for ensuring the machine's longevity and optimal performance.

A well-maintained CNC machine operates smoothly and produces accurate results. Establishing a daily maintenance routine is key to preserving your machine's performance.

Table 14: Daily CNC Machine Maintenance

| Maintenance Tasks | Description |

|---|---|

| Cleaning and Lubrication | Remove debris and apply lubricants to moving parts. |

| Inspection of Components | Regularly check for wear and tear on machine parts. |

| Calibration and Alignment | Ensure the machine remains properly calibrated. |

| Data Backup and Security | Regularly back up CNC programs and data. |

| Operator Training and Safety | Train operators on safe and efficient machine use. |

Even well-maintained CNC machines may encounter issues. Understanding common problems and how to resolve them is essential for keeping your projects on track.

Table 15: Common CNC Machine Issues and Solutions

| Common Issues | Troubleshooting Steps |

|---|---|

| Inaccurate Machining Results | Check for loose components, recalibrate, and ensure toolpath accuracy. |

| Motor Malfunctions | Inspect connections, test motors, and replace faulty components. |

| Software and Programming Errors | Review and debug CNC code, update software, and check for conflicts. |

| Material Feeding Problems | Verify material setup, tool alignment, and feeding mechanisms. |

Table 16: Richconn's Troubleshooting Support

| Troubleshooting Services | Description |

|---|---|

| Expert Problem Solvers | Consult Richconn's experts for troubleshooting assistance. |

| Remote Support | Access remote troubleshooting support for quick solutions. |

| Spare Parts and Repairs | Order genuine spare parts and repair services as needed. |

Prolonging the life of your DIY CNC machine involves implementing best practices and preventive measures.

Table 17: Tips for Extending CNC Machine Lifespan

| Lifespan Extension Strategies | Description |

|---|---|

| Preventive Maintenance | Implement regular maintenance to prevent issues. |

| Temperature and Humidity Control | Ensure a suitable operating environment. |

| Operator Training and Skill Development | Continuously improve operator skills. |

By incorporating these maintenance and care practices, your DIY CNC machine will serve you well for years to come.

Selecting the Right CNC Software

Choosing the perfect software for your project

Overview of popular CNC control software

Writing and Loading CNC Code

The language of CNC machining

How to create, edit, and load CNC code

Mastering CNC Programming Commands

Understanding essential programming commands

Writing code for precision and perfection

In this section, we'll dive into the world of CNC software and programming. Understanding the software tools and programming languages is crucial for controlling your DIY CNC machine effectively.

The choice of CNC control software is a critical decision for your CNC machine. It determines how you interact with the machine and how it interprets your designs.

Table 18: Popular CNC Control Software

| Software Name | Description |

|---|---|

| Mach3 | User-friendly software with extensive features. |

| GRBL | Open-source, highly adaptable software. |

| LinuxCNC | Versatile CNC software for Linux users. |

| UCCNC | Windows-based software with a user-friendly interface. |

| Richconn CNC Software | Professional software for Richconn CNC machines. |

CNC code is the language your machine understands. Learning how to write, edit, and load CNC code is essential for translating your design ideas into precise machine movements.

Table 19: Key Steps in Writing and Loading CNC Code

| Steps | Description |

|---|---|

| CNC Programming Language | Understand the language used by CNC machines. |

| Code Creation and Editing | Create, edit, and fine-tune CNC code for your project. |

| File Loading and Execution | Load CNC programs into your machine's control software. |

| Simulation and Verification | Simulate toolpath and verify code before actual machining. |

Mastering CNC programming commands allows you to control every aspect of your DIY CNC machine's movements. It's a crucial skill for achieving precision and perfection in your projects.

Table 20: Essential CNC Programming Commands

| Programming Commands | Description |

|---|---|

| G-Code | The standard language for CNC machine control. |

| M-Code | Commands for miscellaneous machine functions. |

| Toolpath Generation | Generating toolpaths for various machining operations. |

| Parameters and Variables | Customizing CNC programs using parameters and variables. |

By mastering these essential commands, you'll have complete control over your DIY CNC machine and the ability to bring your creative ideas to life.

CNC Machining in Engraving

Unlocking creativity with precision engraving

Inspiring engraving projects and ideas

CNC Machining in Cutting

The art of precision cutting with your DIY CNC machine

Cutting-edge projects and applications

Real-World DIY CNC Projects

Explore practical DIY CNC applications

Showcase of successful DIY CNC creations

Unleash Your Creativity with Personalized Sculptures

The world of CNC sculpture

Tips and tricks for creating unique sculptures

In this final section, we'll explore the practical applications of your DIY CNC machine and provide inspiration for various creative projects.

CNC machining allows for precise engraving, unlocking your creativity and providing inspiration for a wide range of engraving projects.

Table 21: CNC Engraving Projects

| Engraving Projects | Description |

|---|---|

| Personalized Gifts | Create custom gifts with engraved designs. |

| Signage and Plaques | Craft professional-looking signage and plaques. |

| Artistic Engraving | Explore artistic possibilities with detailed engravings. |

| Jewelry and Accessories | Add intricate patterns to jewelry and accessories. |

The precision of CNC machining is invaluable in cutting applications. Explore the possibilities and applications of precision cutting.

Table 22: CNC Cutting Projects

| Cutting Projects | Description |

|---|---|

| PCB Manufacturing | Create custom printed circuit boards (PCBs). |

| Fabric and Textiles | Precision cutting for textiles and fabrics. |

| Model Making and Prototyping | Craft detailed models and prototypes. |

| Woodworking Projects | Cut intricate designs for woodworking projects. |

Take inspiration from real-world DIY CNC projects and see how others have harnessed the power of CNC machining for their creations.

Table 23: Real-World DIY CNC Projects

| DIY CNC Projects | Description |

|---|---|

| Custom Furniture | Craft custom furniture pieces with precision. |

| 3D Printing and Milling | Combine 3D printing and milling for complex projects. |

| Architectural Models | Create detailed architectural models and prototypes. |

| Precision Instrument Making | Craft precision instruments and mechanical devices. |

CNC machines are perfect for sculpting intricate and personalized creations. Discover the world of CNC sculpture and find tips and tricks for your unique sculptures.

Table 24: Sculpture Tips and Tricks

| Sculpture Tips and Tricks | Description |

|---|---|

| Material Selection | Choose the right materials for your sculptures. |

| Toolpath Strategies | Plan toolpaths for intricate sculpting. |

| Surface Finishing | Enhance the finish and texture of your sculptures. |

With these creative project ideas and tips, you can unleash your imagination and create stunning, personalized CNC masterpieces.

In conclusion, your journey into the world of DIY CNC machines opens up a realm of possibilities. By following the comprehensive guide provided in this article, you'll gain the knowledge and skills needed to build, operate, and create with your very own CNC machine. Embrace the precision, versatility, and creativity that CNC machining offers and make your CNC dreams a reality.

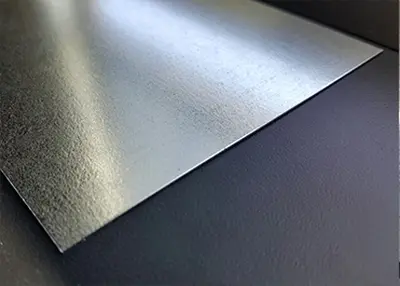

Galvanized Sheet Metal: Unveiling the Power of a Versatile MaterialSeptember 28, 2023When it comes to construction and engineering, one material that stands out for its versatility and durability is galvanized sheet metal. In this comprehensive guide, I will take you on a journey through the world of galvanized sheet metal, exploring its various facets, applications, and even its synergy with CNC technology.view

Galvanized Sheet Metal: Unveiling the Power of a Versatile MaterialSeptember 28, 2023When it comes to construction and engineering, one material that stands out for its versatility and durability is galvanized sheet metal. In this comprehensive guide, I will take you on a journey through the world of galvanized sheet metal, exploring its various facets, applications, and even its synergy with CNC technology.view About PVD Surface Treatment Technology and Its ApplicationSeptember 16, 2022With the rapid development of the automobile industry and the improvement of the technological level, especially the wide application of high-strength plates in automobile sheet metal, the cold work d...view

About PVD Surface Treatment Technology and Its ApplicationSeptember 16, 2022With the rapid development of the automobile industry and the improvement of the technological level, especially the wide application of high-strength plates in automobile sheet metal, the cold work d...view Demystifying CNC Lathe Machining – Unveiling the Precision PowerhouseNovember 3, 2023In the heart of precision manufacturing, CNC (Computer Numerical Control) lathe machining stands as a true marvel. It's a technology that has transformed the way we create parts and components across various industries.view

Demystifying CNC Lathe Machining – Unveiling the Precision PowerhouseNovember 3, 2023In the heart of precision manufacturing, CNC (Computer Numerical Control) lathe machining stands as a true marvel. It's a technology that has transformed the way we create parts and components across various industries.view How Do I Get the Part to Meet the Machining Conditions?October 30, 2023Featuring intricate geometries, often complex CNC parts may require the machining of a series of contours, holes, and recesses to achieve the desired shape and size. Read on to learn more about the complexity of CNC machined part geometries and some of our best tips for reducing design complexity.view

How Do I Get the Part to Meet the Machining Conditions?October 30, 2023Featuring intricate geometries, often complex CNC parts may require the machining of a series of contours, holes, and recesses to achieve the desired shape and size. Read on to learn more about the complexity of CNC machined part geometries and some of our best tips for reducing design complexity.view Plastics Solutions: Choosing the Right Materials for Your PartsOctober 18, 2023There are more than 85,000 commercial options for plastics listed in materials databases. Among them, there are 45 polymer families that can be roughly divided into two categories: Thermosets and Thermoplastics. We focus primarily on the latter category, offering hundreds of engineering thermoplastics through our Express Injection Molding service (see Figure 1). In addition to our in-stock plastics, we can handle many other plastics provided by our customers.view

Plastics Solutions: Choosing the Right Materials for Your PartsOctober 18, 2023There are more than 85,000 commercial options for plastics listed in materials databases. Among them, there are 45 polymer families that can be roughly divided into two categories: Thermosets and Thermoplastics. We focus primarily on the latter category, offering hundreds of engineering thermoplastics through our Express Injection Molding service (see Figure 1). In addition to our in-stock plastics, we can handle many other plastics provided by our customers.view What Is Titanium? (Definition and Guide)February 26, 2024How to choose titanium for your project? Familiarize yourself with the various titanium grades and learn how to choose the most suitable grade for your needs.view

What Is Titanium? (Definition and Guide)February 26, 2024How to choose titanium for your project? Familiarize yourself with the various titanium grades and learn how to choose the most suitable grade for your needs.view