CNC machining has become one of the most critical manufacturing processes used in workshops globally. By adding computer control to previous manual processes, the accuracy and precision of machining parts have made significant advances. Additionally, due to the increasingly complex requirements of various industries, CNC machines have undergone many evolutions to better satisfy customers' needs. The development of CNC machining technology has given birth to various forms and variations, including 3-axis, 4-axis, and 5-axis CNC machines.

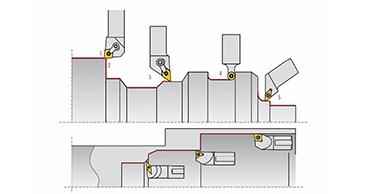

3-axis CNC machining is the simplest and most common form. This process uses rotating tools that move along three axes to machine a fixed workpiece.

Cutting tools move along the X, Y, and Z axes to trim excess material from parts. Additionally, it can even move simultaneously along these multiple axes to create the desired design.

This means that CNC machines can cut into the workpiece from side to side, front to back, and up and down. However, the worktable that holds the fixed workpiece cannot move freely. Despite more advanced systems available in the industry today, 3-axis CNC machining still widely used. So, let's take a look at some advantages of keeping it.

3-axis CNC machining is best suited for quick production of basic geometric shapes and simple components. Additionally, programming and setting up computers for production runs are relatively easy in 3-axis machining.

3-axis CNC machining is a highly versatile part manufacturing process. By simply changing the tools, drilling, milling, and even turning operations can be performed. These machines also integrate with automatic tool changers, thus expanding their capabilities.

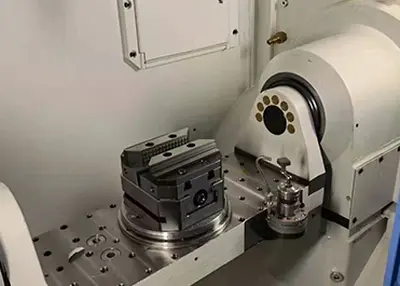

4-axis CNC machining offers a significant upgrade over 3-axis machining. It adds extra freedom through rotary motion, making machining complex features possible and more direct. In 4-axis CNC machining, the tool moves freely along the X, Y, and Z axes to machine the workpiece. However, the workpiece does not remain stationary on the worktable as in 3-axis machining.

4-axis CNC machine tools can rotate the workpiece around the X-axis in a plane called the A-axis. Therefore, you can cut along the contours of the workpiece as the tool moves along it, and the worktable rotates it. Many advantages come from choosing 4-axis CNC machine tools for your manufacturing project.

As the worktable rotates around the X-axis, a 4-axis CNC machine can produce intricate parts with complex details. Additionally, the additional rotation allows for access and machining of parts on other faces at strange angles to create the final product.

4-axis CNC machining can access multiple faces of a workpiece without the need for adjustments or tool replacement. Therefore, parts made with it are highly accurate and in compliance with strict standards.

Most of the work done on a four-axis CNC machine can be completed with just one installation. Therefore, work can proceed smoothly without the need to stop or intervene to replace fixtures and tools. Additionally, production costs are significantly reduced, especially compared to 3-axis machining, as multiple fixtures are not required to secure the part.

5-axis CNC machining is the most accurate and advanced method for manufacturing complex, precision metal parts in a workshop. In a 5-axis CNC machine, the tool moves on the X, Y, and Z axes, just like in a 3-axis machine. In addition, the worktable can rotate the workpiece around the X and Y axes.

These rotating planes are called the A and B axes, respectively. These additional rotations open up other faces of the workpiece that were previously inaccessible for machining. Therefore, precise 3D machining can be performed on a five-axis CNC machine because the machine moves on the XYZ axes while simultaneously rotating on the A and B planes.

As a professional CNC China company, Richconn provides both 4-axis and 5-axis CNC machining services. Feel free to contact us at any time.

CNC Machined Bicycle Parts: Elevate Your Cycling Experience with Richconn PrecisionNovember 13, 2023In the realm of cycling, precision matters. Every curve, every gear, and every component plays a crucial role in enhancing the rider's experience. That's where Richconn comes in – a name synonymous with excellence in CNC machining for bicycle parts.view

CNC Machined Bicycle Parts: Elevate Your Cycling Experience with Richconn PrecisionNovember 13, 2023In the realm of cycling, precision matters. Every curve, every gear, and every component plays a crucial role in enhancing the rider's experience. That's where Richconn comes in – a name synonymous with excellence in CNC machining for bicycle parts.view How do you charge for sleeve parts machining?October 31, 2023Sleeve parts machining charges will be involved in the structural design, machining process, hole size, material selection and other requirements, any one of the different processing needs will lead to a great difference in price, so the need for a relatively accurate quote must provide a complete design drawings, engineers will be based on the design of the drawings labeled materials, dimensions, process, accuracy, structure, table at the detailed parameters such as calculating the accurate quote.view

How do you charge for sleeve parts machining?October 31, 2023Sleeve parts machining charges will be involved in the structural design, machining process, hole size, material selection and other requirements, any one of the different processing needs will lead to a great difference in price, so the need for a relatively accurate quote must provide a complete design drawings, engineers will be based on the design of the drawings labeled materials, dimensions, process, accuracy, structure, table at the detailed parameters such as calculating the accurate quote.view Unraveling the World of Machined Springs: Your Ultimate GuideNovember 9, 2023As a CNC machining service provider, we at Richconn understand the significance of precision engineering and how it's all about the details. In the realm of mechanical components, one topic that piques the curiosity of engineers, manufacturers, and professionals alike is -Machined Springs. In this comprehensive guide, I will walk you through the intricacies of Machined Springs, from the fundamentals to their applications, performance characteristics, manufacturing processes, and more.view

Unraveling the World of Machined Springs: Your Ultimate GuideNovember 9, 2023As a CNC machining service provider, we at Richconn understand the significance of precision engineering and how it's all about the details. In the realm of mechanical components, one topic that piques the curiosity of engineers, manufacturers, and professionals alike is -Machined Springs. In this comprehensive guide, I will walk you through the intricacies of Machined Springs, from the fundamentals to their applications, performance characteristics, manufacturing processes, and more.view Precautions for Using CNC TurningApril 25, 2023Turning is a cutting method that uses the rotation of the workpiece relative to the tool on a lathe to perform cutting operations. CNC turning allows the workpiece rather than the tool to provide most...view

Precautions for Using CNC TurningApril 25, 2023Turning is a cutting method that uses the rotation of the workpiece relative to the tool on a lathe to perform cutting operations. CNC turning allows the workpiece rather than the tool to provide most...view How to Remove Chrome Plating Easily? (A Complete Guide 2024)March 11, 2024Learn how to remove chrome plating effectively with our comprehensive guide and get expert tips for successfully stripping chrome from metal surfaces.view

How to Remove Chrome Plating Easily? (A Complete Guide 2024)March 11, 2024Learn how to remove chrome plating effectively with our comprehensive guide and get expert tips for successfully stripping chrome from metal surfaces.view American Scientific Research Has Found A Fast And Effective Processing Method Of Low-Temperature Titanium AlloyMay 30, 2022Titanium is widely used in the aerospace industry because of its high strength and low density. However, compared with steel, aluminum, and other metals, its hot processing cost is high and it is at a...view

American Scientific Research Has Found A Fast And Effective Processing Method Of Low-Temperature Titanium AlloyMay 30, 2022Titanium is widely used in the aerospace industry because of its high strength and low density. However, compared with steel, aluminum, and other metals, its hot processing cost is high and it is at a...view

EN

EN

ru

ru