As businesses seek reliable partners for their CNC machining needs, understanding the criteria for selecting the right manufacturer becomes imperative. This choice of the CNC machining manufacturer can significantly impact the quality, cost, and timely delivery of your products.

When choosing a CNC machining manufacturer, it’s essential to consider a variety of factors, from technical expertise to production capacity, quality assurance, and more.

The first step in choosing the right CNC machining manufacturer is understanding your specific needs and goals. This involves identifying the type of parts you need to produce, the materials you will be working with, the precision required, and the volume of production.

Providing a manufacturer with comprehensive information about your project can help them better understand your needs and propose the most suitable solutions. This includes technical drawings, material specifications, tolerance requirements, post-processing needs, and any other relevant details.

A manufacturer’s industry experience can provide insights into their ability to handle various challenges, adapt to changes, and deliver high-quality products consistently. On the other hand, technical expertise reflects the manufacturer’s proficiency in various machining techniques, understanding of materials, and ability to optimize the CNC machining manufacturing process for efficiency and precision.

For example, Richconn, with over 12 years of industry experience, has demonstrated its ability to deliver a wide range of CNC machining services. Their expertise spans various machining types, including CNC Turning, CNC Milling, and 4/5 Axis CNC Machining, among others. This breadth and depth of experience and expertise enable them to handle diverse customer requirements and deliver high-quality parts and molds.

In CNC machining, a manufacturer’s capabilities and technology include the machinery they use, the software that drives their processes, and their ability to leverage the latest technological advancements.

Richconn excels in manufacturing with a suite of state-of-the-art machinery. From CNC milling machines to wire EDM and CNC lathes, their equipment arsenal reflects a capacity to address a spectrum of project requirements.

Flexibility and scalability often represent the manufacturer’s ability to adapt to changes and scale operations. A flexible manufacturer can quickly adjust their production processes to accommodate these changes without significant delays or cost increases. On the other hand, scalability refers to the manufacturer’s ability to increase production capacity to meet growing demand. A scalable manufacturer has the infrastructure and resources necessary to ramp up production quickly and efficiently when needed.

Quality assurance and certifications serve as a testament to a manufacturer’s commitment to maintaining high standards of quality and reliability.

Quality assurance involves a set of procedures designed to ensure that the products manufactured meet the specified requirements consistently. These procedures include regular inspections, testing, and corrective actions to eliminate any potential defects. Certifications are another aspect that provides an objective validation of a manufacturer’s capabilities and adherence to industry standards.

Richconn's stringent dedication to meeting international standards is evident through its adherence to ISO 9001 and ISO 13485 certifications.

Effective communication can ensure a smooth and efficient production process, from the initial design phase to the final product delivery. Richconn stands out for its commitment to fostering transparent and collaborative relationships with clients. It works closely with its clients, providing valuable input based on its extensive experience in the CNC machining industry.

It’s important to understand that cost is not just about the initial price quoted for the project when choosing a CNC machining manufacturer.

1. Direct Costs

Direct costs include the cost of materials, labor, and the actual machining process. These are usually the most apparent costs and will be explicitly stated in the quote provided by the manufacturer.

2. Indirect Costs

Indirect costs, on the other hand, are not always immediately apparent. These include costs related to delays, poor quality, and lack of communication.

3. Value for Money

Finally, it’s necessary to consider the value of money as well. This involves looking at the overall value provided by the manufacturer, including the quality of their products, their reliability, and their after-sales service.

Lead time refers to the amount of time it takes for the manufacturer to complete your order from the moment it is placed. The lead time can significantly impact your production schedule, especially if you’re working on a tight deadline. A shorter lead time means that you can get your parts faster, allowing you to maintain a steady production flow and meet your project deadlines.

Meanwhile, turnaround times can vary greatly between manufacturers. Some may offer quick turnaround times as part of their standard service, while others may require additional fees for expedited services.

The location of the CNC machining manufacturers can have a direct impact on the logistics costs and delivery times. A manufacturer located closer to your business or your market can reduce transportation costs and lead times. This is why searches for “CNC machining shops” or “CNC machining shops near me” are common, as proximity can often translate into savings and efficiency. Meanwhile, effective logistics management can reduce costs, improve delivery times, and ensure the smooth operation of the supply chain.

A CNC machining manufacturer's approach to conflict resolution and warranty policies speaks volumes about its commitment to customer satisfaction and quality assurance.

A reputable manufacturer should have a clear and efficient conflict resolution policy, emphasizing open communication, thorough investigation of issues, fair solution proposals, and effective implementation to prevent recurrence. Similarly, robust warranty policies underscore the manufacturer's confidence in their products, covering a wide range of potential issues, offering a reasonable duration, and providing a straightforward and customer-friendly claim process.

Choosing the right CNC machining manufacturer is a multifaceted decision that requires careful consideration of various factors. From assessing technological capabilities and certifications to understanding cost structures and logistics, each aspect plays a crucial role in ensuring a successful manufacturing partnership. By taking the time to evaluate each of these elements, you can ensure that you choose a CNC machining manufacturer that not only meets your immediate needs but also aligns with your long-term business goals.

What Are the General Types of Measurement Methods for Machining Accuracy of Machine Parts?October 27, 2023Machining accuracy is the actual size, shape, position of the surface of the machined part three kinds of geometric parameters and drawings required by the ideal degree of compliance with the geometric parameters.view

What Are the General Types of Measurement Methods for Machining Accuracy of Machine Parts?October 27, 2023Machining accuracy is the actual size, shape, position of the surface of the machined part three kinds of geometric parameters and drawings required by the ideal degree of compliance with the geometric parameters.view Unveiling the World of Helical Machined Springs: A Comprehensive ExplorationNovember 15, 2023Embarking on a journey through the intricate world of helical machined springs is more than just an exploration of engineering marvels – it's a pathway to unlocking innovation, efficiency, and reliability in diverse industries. In this article, I'll guide you through the essential aspects of helical machined springs, from their fundamental workings to practical applications and market trends.view

Unveiling the World of Helical Machined Springs: A Comprehensive ExplorationNovember 15, 2023Embarking on a journey through the intricate world of helical machined springs is more than just an exploration of engineering marvels – it's a pathway to unlocking innovation, efficiency, and reliability in diverse industries. In this article, I'll guide you through the essential aspects of helical machined springs, from their fundamental workings to practical applications and market trends.view Unlocking the World of Machined Bushes: Your Comprehensive GuideNovember 8, 2023Are you ready to delve into the fascinating world of machined bushes? If you're curious about what machined bushes are, how they are made, where they are used, and how to choose the right ones for your specific needs, you've come to the right place. I'm here to guide you through this journey of discovery.view

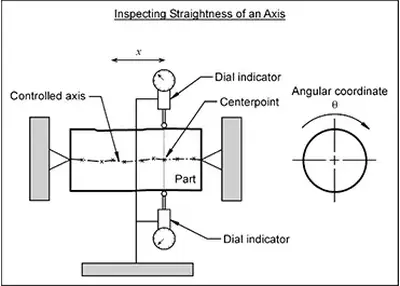

Unlocking the World of Machined Bushes: Your Comprehensive GuideNovember 8, 2023Are you ready to delve into the fascinating world of machined bushes? If you're curious about what machined bushes are, how they are made, where they are used, and how to choose the right ones for your specific needs, you've come to the right place. I'm here to guide you through this journey of discovery.view Understanding Straightness: Unveiling Precision in EngineeringNovember 21, 2023Welcome to a journey through the realm of straightness—a fundamental concept in the world of engineering and precision manufacturing. Ever wondered how straightness impacts the quality of products or the efficiency of industrial processes? Join me as we explore the nuances and practical applications of this crucial element.view

Understanding Straightness: Unveiling Precision in EngineeringNovember 21, 2023Welcome to a journey through the realm of straightness—a fundamental concept in the world of engineering and precision manufacturing. Ever wondered how straightness impacts the quality of products or the efficiency of industrial processes? Join me as we explore the nuances and practical applications of this crucial element.view Electrophoretic Surface Treatment Process Characteristics and Main CharacteristicsSeptember 16, 20221. Characteristics of electrophoresis surface treatment processElectrophoretic paint film has the advantages of full, uniform, flat and smooth coating. The hardness, adhesion, corrosion resistance, im...view

Electrophoretic Surface Treatment Process Characteristics and Main CharacteristicsSeptember 16, 20221. Characteristics of electrophoresis surface treatment processElectrophoretic paint film has the advantages of full, uniform, flat and smooth coating. The hardness, adhesion, corrosion resistance, im...view The Working Principle of CNC Cutting Aluminum SheetsFebruary 29, 2024The Intricacies of CNC Cutting Aluminum SheetsIn the intricate world of manufacturing and fabrication, CNC cutting aluminum sheets has become a cornerstone practice, heralding a new era of precision a...view

The Working Principle of CNC Cutting Aluminum SheetsFebruary 29, 2024The Intricacies of CNC Cutting Aluminum SheetsIn the intricate world of manufacturing and fabrication, CNC cutting aluminum sheets has become a cornerstone practice, heralding a new era of precision a...view

EN

EN

ru

ru