When it comes to projects requiring materials with low friction coefficient, tensile strength, and rigidity, Acetal and Delrin stand out as excellent options. While both materials share similarities, it is essential to understand their differences for proper application. This article explores the comparison between Acetal and Delrin, shedding light on everything you need to know about these thermoplastic polymers.

Delrin resin, also known as acetal Delrin or Polyoxymethylene (POM), is a type of acetal homopolymer. It stands out as a reliable and uniform material due to its repeated cyclic CH2O bonds that create a consistent framework. Density of Delrin is 1420 kg/m3. Delrin is particularly renowned for its exceptional strength and hardness, making it a top choice among engineering thermoplastics. Moreover, Delrin possesses properties that make it an excellent substitute for metals in various applications.

When people are curious about Delrin material, they often ask, "What is Delrin material?" To answer that question, we can provide a list of its properties that help you understand this material better.

Recyclability

Much like acetal, Delrin is also recyclable, offering environmental benefits after use. With a melting point of approximately 120 degrees Celsius, the material can be recycled, contributing to sustainability efforts.

Excellent Flexibility

Delrin displays a notable degree of flexibility, making it a popular choice for technical joints. Its toughness remains stable within a temperature range spanning from -40 degrees Celsius to 90 degrees Celsius.

Wide Temperature Range

Delrin exhibits a wide temperature range of -40 degrees Celsius to 120 degrees Celsius. However, its ability to withstand high temperatures may be limited for extended periods.

Excellent Abrasion Resistance

When it comes to technical applications that entail long-term and continuous load-bearing requirements, Delrin is often preferred due to its exceptional fatigue resistance. It demonstrates minimal permanent deformation.

Hardness and Strength

Delrin demonstrates remarkable hardness, elasticity, and strength, attributed to its high crystallinity. Its mechanical properties surpass those of acetal, making it a preferred choice.

Low Moisture Absorption

With a specific melting point, Delrin can readily liquefy and effectively fill molds, accelerating the mold placement process and optimizing production cycles.

Furthermore, Delrin boasts several notable properties, including high creep resistance, outstanding impact resistance, elevated resistivity, and a high flexural modulus.

Delrin 150

This grade is known for its excellent mechanical properties, including high strength, rigidity, and resistance to warping at high temperatures.

Delrin 100 AF Blend 13% PTFE-filled

This grade includes a 13% polytetrafluorethylene (PTFE) filler, providing enhanced durability, wear resistance, and natural lubricity.

Delrin (30% Glass Filled)

With a 30% glass fiber filler, this grade exhibits unmatched impact resistance, making it suitable for applications subjected to constant stress.

Delrin acetal AF 20% PTFE-filled (Full Strength)

This grade incorporates 20% PTFE fibers, resulting in improved rigidity, strength, and durability. It finds applications in the production of submarine parts for the Navy.

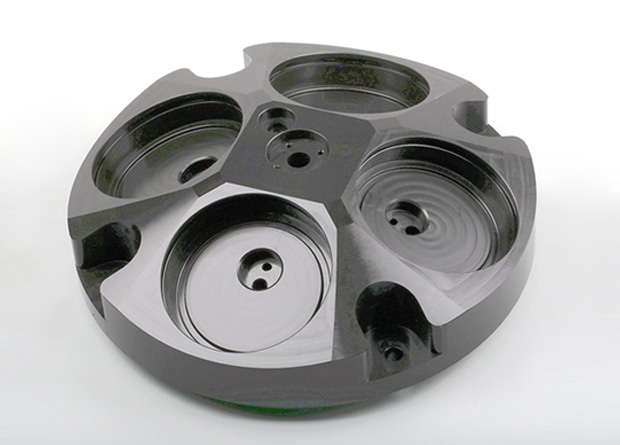

Gears and bearings in machinery and automotive applications

Electrical connectors and insulators

Surgical instruments and medical device components

Consumer goods such as zippers and fasteners

Conveyor belts and rollers

Plumbing fittings and valves

Automotive fuel system components

Sports equipment components like ski bindings and archery bows

Musical instrument components like guitar picks and drumstick tips

Aerospace applications such as aircraft interiors and control system components

Acetal, also known as polyoxymethylene (POM), polyacetal, polyformaldehyde, or polymethylene, is a type of engineering thermoplastic. Its chemical structure, R2C(OR')2, includes a central carbon atom bonded to two oxygen atoms (CH2O). Acetal resin is a semi-crystalline material widely used in various manufacturing processes. It offers similar properties to metal materials, making it a popular choice as a replacement for metal parts. Applications made from acetal often require high friction characteristics, dimensional stability, hardness, and exceptional durability. The formula of acetal can be adjusted based on specific production requirements, although the differences are negligible.

Recyclability

Acetal, being a thermoplastic, is recyclable. With a melting point ranging from approximately 162 degrees Celsius to 175 degrees Celsius, products made from acetal can be melted down and recycled after use. This recyclability factor contributes to acetal being considered an environmentally friendly material.

Heat Resistance

Acetal demonstrates good heat resistance, allowing it to withstand temperatures of up to nearly 160 degrees Celsius. This property enables products made from acetal to maintain dimensional stability and retain their mechanical properties even when exposed to high temperatures or hot water for extended periods.

Impressive Chemical Resistance

Acetal exhibits strong resistance to both organic and inorganic acids, as well as various solvents. This chemical resistance contributes to its overall durability and longevity.

Abrasion Resistance

The low friction coefficient of acetal plastic makes it highly resistant to external mechanical impacts and less prone to abrasion.

Outstanding Durability

Acetal's outstanding durability enables it to function as a metal substitute in numerous manufacturing applications.

Enhanced Reinforcing Ability

Acetal can easily be combined with reinforcing materials, such as fiberglass, allowing for enhanced properties like increased strength, toughness, and hardness through molecular bonding with other materials.

Copolymer Acetal (POM-C)

Copolymer acetal (POM-C) contains different monomeric units within the repeating CH2O units. It offers excellent dimensional stability, chemical resistance, and abrasion resistance. It is commonly used in injection molding and plastic extrusion processes. Copolymer acetal is available in a range of colors, including black, blue, red, green, and brown. Some well-known trade names for copolymer acetal include Celcon®, Duracon®, Hostaform®, Tepcon®, and Ultraform®.

Homopolymer Acetal

Homopolymer acetal, known by its major trade name Delrin®, does not have any alterations in its repeating CH2O units. Delrin® is a widely used material known for its strength, stiffness, and dimensional stability. It is often utilized in various applications. There are also acetals that exhibit both homopolymer and copolymer characteristics, such as Acetron®, Kepital® POM, Sustarin® C, Tecaform®, and Tenac™-C.

Gears and bearings in machinery and automotive applications

Electrical connectors and insulators

Surgical instruments and medical device components

Consumer goods such as zippers and fasteners

Conveyor belts and rollers

Plumbing fittings and valves

Automotive fuel system components

Sports equipment components like ski bindings and archery bows

Musical instrument components like guitar picks and drumstick tips

1. Composition

Acetal is a copolymer that incorporates additional monomers at specific intervals within the polymer chain, whereas Delrin is a homopolymer composed of repeating units with precise end caps. This difference in composition affects the overall structure and properties of the materials.

2. Crystalline Structure

Delrin has a highly crystalline structure, with its repeating units and end caps organized in a precise manner. The crystalline structure imparts strength and rigidity to Delrin. On the other hand, the presence of additional monomers in the acetal structure disrupts the crystal organization, resulting in a less ordered structure. This can affect the mechanical and thermal properties of the material.

3. Hardness

Delrin is known for its impressive hardness, which is typically rated at 86 Shore D, slightly higher than the hardness typically found in acetal copolymers, which typically range around 85 Shore D. This higher hardness in Delrin enhances its resistance to impacts and abrasion, as well as reducing friction for smoother movement over other surfaces.

4. Chemical Resistance

Acetal copolymers generally exhibit superior chemical resistance compared to Delrin, particularly against hot water and strong caustic solutions with elevated pH levels. However, it is important to note that Delrin still possesses commendable chemical resistance and remains unaffected by fungi, insects, or other organisms.

5. Temperature Tolerance

Delrin has a wider temperature tolerance range, typically ranging from -40°C to 120°C, ensuring its dimensional stability and maintaining its mechanical properties over a wide range of temperatures. Acetal copolymers, while exhibiting a good operating range of up to 100°C, can still withstand short-term usage at approximately 140°C. This makes Delrin more suitable for applications where higher temperature resistance is required.

6. Strength

Delrin stands out for its impressive flexural yield strength and tensile strength. It typically has a flexural yield strength of around 11,000 psi and a tensile strength of approximately 13,000 psi. Acetal copolymers also exhibit respectable strength, with a flexural yield strength of around 9,500 psi and a tensile strength of approximately 12,000 psi. Both materials offer robust structural capabilities, but Delrin showcases slightly higher strength characteristics.

7. Porosity

Delrin has a lower-density or porous center, allowing for the potential inclusion of small bubbles or voids. This property enables the material to absorb gases and liquids to a certain extent. In comparison, acetal copolymers are non-porous, making them particularly suitable for applications where porosity is undesirable, such as in the food and medical industries.

8. Applications

Both Delrin and acetal copolymers find widespread use across numerous industrial and mechanical applications. Delrin's exceptional mechanical properties make it an ideal choice for parts requiring a strong POM material, such as gears, bearings, and bushings. Acetal copolymers, with their excellent chemical resistance, are commonly used in applications requiring resistance to chemicals, solvents, and automotive fuel system components, among others.

9. Cost

POM materials, including acetal copolymers and Delrin, are generally cost-effective compared to other engineering plastics. However, Delrin may command a relatively higher price due to its renowned brand reputation, superior mechanical attributes, and wider range of applications. The overall cost will also depend on factors such as purchase volume, supplier, and availability.

Richconn is a well-known and highly respected provider of CNC machining services. We have built a strong reputation for delivering exceptional injection molding services that are known for their quality and reliability. Our utmost priority is customer satisfaction, and we are dedicated to providing precision engineering solutions. We offer a diverse range of parts with flexible dimensions, catering to a variety of requirements - from small components to large-scale projects. You can trust Richconn to meet your CNC machining needs and exceed your expectations.

Good News! Here is what you can get from Richconn.

Thorough understanding of parts manufacturing: Our technicians have a comprehensive knowledge of injection molding, CNC machining, and 3D printing processes.

Quick analysis and quote: Upon uploading your CAD files, our teams perform a detailed analysis and provide you with a quote in a timely manner.

Precision machining expertise: Our skilled team of precision machining experts ensures the accurate production of your products.

High-quality standards: Our highly trained quality control experts, engineers, and designers ensure that all CNC machined parts meet and exceed industry standards in terms of durability and functionality.

One-stop outsourcing solution: We offer a range of plastic parts production services, including injection molding, CNC machining, and 3D printing.

Affordable services: We provide cost-effective services by utilizing automated machines and employing strategic and creative experts.

Streamlined workflows: Our automated machines and efficient processes enable us to deliver your products in a timely manner.

Extensive experience: With our expertise in parts manufacturing, we have successfully served various industries and clients.

In general, both acetal and Delrin materials are commonly used in various industrial and mechanical designs. Based on the properties outlined above, it can be concluded that Delrin is a superior choice for applications that require durability, hardness, and flexibility. On the other hand, acetal is an ideal option for products that need chemical resistance and long-term exposure to solvents.

Acetal and Delrin are excellent engineering plastics suitable for technical applications in various industries. When selecting the appropriate plastic for a project, it is essential to consider the distinct characteristics of acetal and Delrin, as well as the specific requirements of the desired product. Visit Richconn today to gain valuable insights and guidance for your upcoming projects.

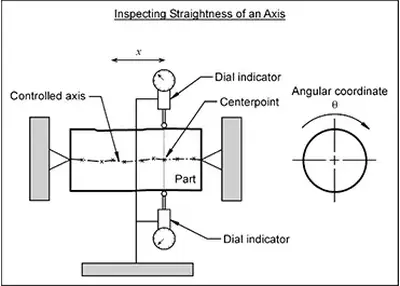

Understanding Straightness: Unveiling Precision in EngineeringNovember 21, 2023Welcome to a journey through the realm of straightness—a fundamental concept in the world of engineering and precision manufacturing. Ever wondered how straightness impacts the quality of products or the efficiency of industrial processes? Join me as we explore the nuances and practical applications of this crucial element.view

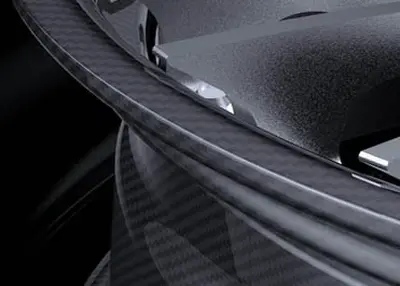

Understanding Straightness: Unveiling Precision in EngineeringNovember 21, 2023Welcome to a journey through the realm of straightness—a fundamental concept in the world of engineering and precision manufacturing. Ever wondered how straightness impacts the quality of products or the efficiency of industrial processes? Join me as we explore the nuances and practical applications of this crucial element.view Revolutionizing Automotive Manufacturing with CNC Cutting Aluminum SheetsFebruary 29, 2024The Rise of CNC Cutting in Automotive ManufacturingIn the fast-paced world of automotive manufacturing, precision and efficiency are key factors that can make or break a company's success. One tec...view

Revolutionizing Automotive Manufacturing with CNC Cutting Aluminum SheetsFebruary 29, 2024The Rise of CNC Cutting in Automotive ManufacturingIn the fast-paced world of automotive manufacturing, precision and efficiency are key factors that can make or break a company's success. One tec...view PVD Surface Treatment: Achieving Durability and AestheticsAugust 14, 2023PVD (Physical Vapor Deposition) surface treatment process is usually used to create hard, durable and beautiful surfaces. It involves applying a thin layer of metal or ceramic coating onto an object t...view

PVD Surface Treatment: Achieving Durability and AestheticsAugust 14, 2023PVD (Physical Vapor Deposition) surface treatment process is usually used to create hard, durable and beautiful surfaces. It involves applying a thin layer of metal or ceramic coating onto an object t...view Engineers Must Read: The Art of Wire Cutting and Complementary ProcessingAugust 24, 2023Introduction:In the world of engineers, the collision of creativity and technology is always fascinating. This article will explore an intriguing topic that is a must-read for engineers: the art of wi...view

Engineers Must Read: The Art of Wire Cutting and Complementary ProcessingAugust 24, 2023Introduction:In the world of engineers, the collision of creativity and technology is always fascinating. This article will explore an intriguing topic that is a must-read for engineers: the art of wi...view How to Find an Excellent Precision Machining Manufacturer in China?October 19, 2023China is one of the more developed countries in the global manufacturing industry, so it is not difficult to find an excellent precision machining manufacturer in China, but how to find a reliable quality, good service, reasonable price precision machining manufacturer in China, it is necessary for consumers to make a careful assessment when choosing.view

How to Find an Excellent Precision Machining Manufacturer in China?October 19, 2023China is one of the more developed countries in the global manufacturing industry, so it is not difficult to find an excellent precision machining manufacturer in China, but how to find a reliable quality, good service, reasonable price precision machining manufacturer in China, it is necessary for consumers to make a careful assessment when choosing.view What Is Mechanical Rack: Picking the Best for Your Custom PartsMay 22, 2024Delve into the world of equipment racks with this comprehensive article. Learn about their structure, design principles, materials, manufacturing processes, installation, commissioning, and more.view

What Is Mechanical Rack: Picking the Best for Your Custom PartsMay 22, 2024Delve into the world of equipment racks with this comprehensive article. Learn about their structure, design principles, materials, manufacturing processes, installation, commissioning, and more.view