Prototypes are especially important in the process of product development, allowing designers and manufacturers to test and refine their ideas before mass production. This article will delve into the world of prototype manufacturing, exploring the process, and benefits, and providing essential tips for successful prototype development. From ideation to testing, we will guide you through the key steps involved in prototype manufacturing, highlight the advantages it offers, and offer valuable insights to help you navigate the process effectively.

Prototype manufacturing is the process of creating a functional prototype or sample of a product before mass production. It involves making a limited number of units using the specified manufacturing processes and materials to test and validate the product design, functionality, and performance. Prototype manufacturing allows product designers and manufacturers to identify and resolve any issues or improvements needed in the design or production process before investing in mass production. It helps in refining the product and reducing the risk of costly errors or failures in later stages of manufacturing.

A prototype serves as a tangible representation of an idea and allows designers and engineers to test and refine their product design. The process of prototype development services involves several key steps:

During the idea generation, the prototype manufacturer generates a multitude of ideas and evaluates them to identify the most promising ones. The objective of brainstorming is to generate a high quantity of ideas that can be refined and assessed for feasibility and effectiveness. From this pool of ideas, a strong concept is selected and further developed into a prototype. Idea generation fosters innovative thinking and nurtures creativity by encouraging the exploration of original ideas.

Once the concept is developed, a rough draft or digital model is created to visualize the product idea. It is crucial to test the prototype at this stage to identify any potential issues or problem areas. Multiple iterations of the rough draft may be necessary to refine the design and ensure it meets the required specifications.

Creating a physical prototype is a crucial step in the development process. It involves transforming the rough draft into a tangible representation of the product. 3D printing and CNC prototyping are two commonly prototype tooling for creating physical prototypes.

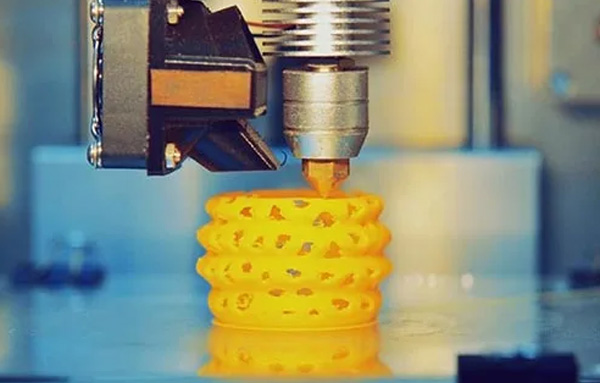

3D Printing

With 3D printing, a digital model of the prototype is created using computer-aided design (CAD) software. The digital model is then sliced into thin layers, and the 3D printer builds the physical prototype layer by layer using materials like plastic, resin, or metal. This method allows for rapid and cost-effective production of prototypes with complex geometries.

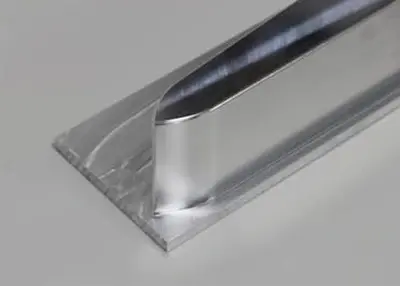

CNC Prototyping

CNC prototype involves using computer-controlled cutting tools to shape the prototype from materials such as wood, metal, or plastic. The CAD design of prototype CNC machining is translated into machine code, which guides the CNC machine in precisely cutting, drilling, and shaping the material to create the physical prototype. This method is ideal for prototypes requiring high precision and materials that cannot be 3D printed.

Some factors to consider before prototype development is:

1. Cost

Evaluate the budget required for developing the prototype and the potential manufacturing costs for the final product. Consider the expenses associated with materials, labor, equipment, and any external services required.

2. Tolerance Variance

Define the acceptable margins of error in the prototype's measurements and assess whether the prototype can achieve them. This will help maintain accuracy and precision in the final product.

3. Material Selection

Select appropriate materials for the prototype, considering factors such as durability, cost-effectiveness, and functionality. Evaluate the availability and suitability of materials based on the intended use and requirements of the prototype.

4. Appropriate Tools

Choose the appropriate technologies, software, and tools for creating the prototype. This ensures efficient development, facilitates further iterations if needed, and ensures the prototype's effective and functional design.

5. Functionality

Clearly define the expected functionality of the prototype and ensure that it aligns with the user's needs and requirements. Consider how the prototype will address key functionalities and how it will provide a solution to specific problems.

The development of a prototype offers several benefits for product development, which include:

1. Risk Reduction

Prototyping helps identify and address potential issues early on, reducing the risk of costly mistakes during mass production.

1. Cost Savings

By addressing design flaws and functionality issues in the prototype stage, you can avoid expensive rework or changes later in the manufacturing process.

2. Improved Communication

A physical prototype allows for better communication and collaboration among team members, stakeholders, and customers, leading to a clearer understanding of the product.

3. User Feedback

Prototyping enables gathering valuable feedback from potential users, helping to refine the product and meet their needs effectively.

4. Optimal Design and Functionality

Through iteration and testing, prototyping helps optimize the product's design and ensure it functions as intended.

5. Enhanced Marketability

A functional prototype can generate interest, and excitement, and showcase the value proposition of the product to potential investors or customers, increasing its market appeal.

Once the prototype has been constructed, it is crucial to conduct thorough testing to ensure it meets user requirements and performs as intended. Here is the complete procedure for testing a prototype:

1. Define Goals and Questions

Clearly establish the goals of the testing phase and outline the specific questions you want to answer through the testing process.

2. Recruit Target Participants

Select participants who match the target user demographic for the prototype. These participants should have the characteristics and behaviors of the intended users.

3. Gather Feedback and Data

Conduct the testing sessions to gather feedback from participants. Utilize methods such as surveys, interviews, observation, and usability tests to collect relevant data.

4. Analyze Feedback

Carefully analyze the feedback and data collected from the testing sessions. Look for patterns, trends, and common issues to identify areas that need improvement or adjustments.

During the testing process, certain questions need to be answered:

Does the prototype meet user needs?

Is it easy to use and navigate?

Are there any usability issues or challenges encountered by participants?

Is the prototype visually appealing and engaging?

If you are contemplating the use of rapid prototype services but are uncertain about their suitability for your parts, simply reach out to Richconn. With a skilled team of engineers, we can provide expert guidance on the ideal prototype manufacturing process for your specific parts. Our dedicated prototype developers ensure that CNC rapid prototyping is fabricated in accordance with client specifications, a fact that our many satisfied clients can attest to. Feel free to contact Richconn, the prototype development company for the best advice and reliable prototype manufacturing services.

This comprehensive guide on the process of making a prototype offers explanations of the steps involved and highlights the importance of testing. If you are interested in further exploring the topic of prototyping, it is recommended to reach out to Richconn for additional information and assistance. Their expertise in this field ensures reliable guidance and support throughout the prototyping journey.

Electrophoresis Metal Coating in Laboratory AutomationFebruary 29, 2024Navigating Precision in Laboratory AutomationIn the dynamic landscape of scientific research, the central axis of efficiency revolves around laboratory automation. At the nucleus of this efficiency li...view

Electrophoresis Metal Coating in Laboratory AutomationFebruary 29, 2024Navigating Precision in Laboratory AutomationIn the dynamic landscape of scientific research, the central axis of efficiency revolves around laboratory automation. At the nucleus of this efficiency li...view Welding Sheet Metal: How to Weld Sheet Metal? (Techniques & Tips)August 24, 2023Sheet metal welding is the process of using heat and electricity to join thin pieces of metal together. This process is essential for many applications, such as making custom products, repairing damag...view

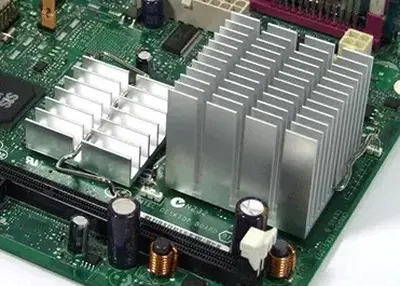

Welding Sheet Metal: How to Weld Sheet Metal? (Techniques & Tips)August 24, 2023Sheet metal welding is the process of using heat and electricity to join thin pieces of metal together. This process is essential for many applications, such as making custom products, repairing damag...view Heat Sinks: What They Are, How They Work, and How to Design ThemDecember 8, 2023Have you ever wondered how your laptop, smartphone, or gaming console can run so fast without overheating? The answer is heat sinks. Heat sinks are devices that help to cool down electronic components by transferring heat away from them. They are essential for ensuring the reliability and performance of many modern devices.view

Heat Sinks: What They Are, How They Work, and How to Design ThemDecember 8, 2023Have you ever wondered how your laptop, smartphone, or gaming console can run so fast without overheating? The answer is heat sinks. Heat sinks are devices that help to cool down electronic components by transferring heat away from them. They are essential for ensuring the reliability and performance of many modern devices.view Transparent Aluminum: A Revolutionary Material for the FutureDecember 6, 2023Transparent aluminum is a fascinating and futuristic material that has many advantages and disadvantages. It is a material that was first mentioned in the 1986 science fiction film Star Trek IV: The Voyage Home, where the crew of the USS Enterprise used it to construct a tank for transporting two humpback whales.view

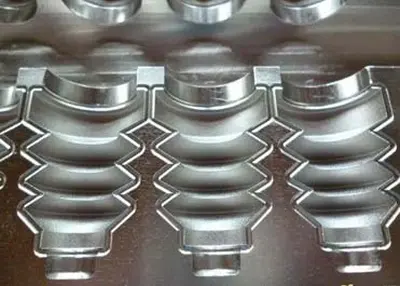

Transparent Aluminum: A Revolutionary Material for the FutureDecember 6, 2023Transparent aluminum is a fascinating and futuristic material that has many advantages and disadvantages. It is a material that was first mentioned in the 1986 science fiction film Star Trek IV: The Voyage Home, where the crew of the USS Enterprise used it to construct a tank for transporting two humpback whales.view Must-Read for Procurement Professionals! 2023 Report on China's Rubber Molds and Parts IndustryAugust 16, 2023Overview: This report provides an in-depth analysis of the development trends, competitive landscape, and key characteristics of China's rubber molds and parts industry in 2023. It serves as an im...view

Must-Read for Procurement Professionals! 2023 Report on China's Rubber Molds and Parts IndustryAugust 16, 2023Overview: This report provides an in-depth analysis of the development trends, competitive landscape, and key characteristics of China's rubber molds and parts industry in 2023. It serves as an im...view 3D Printing Materials GuideOctober 9, 20233D printing, also known as additive manufacturing, has a wide range of materials available for creating objects. The choice of material depends on factors such as the desired properties of the final o...view

3D Printing Materials GuideOctober 9, 20233D printing, also known as additive manufacturing, has a wide range of materials available for creating objects. The choice of material depends on factors such as the desired properties of the final o...view

EN

EN

ru

ru