In the intricate world of manufacturing and fabrication, CNC cutting aluminum sheets has become a cornerstone practice, heralding a new era of precision and efficiency. This blog aims to not only unravel the working principle behind CNC cutting but also shed light on its myriad benefits and diverse applications across various industries.

CNC cutting aluminum sheets is a meticulous process orchestrated by Computer Numerical Control (CNC) machines. The journey commences with the creation of a design using Computer-Aided Design (CAD) software. This design metamorphoses into a digital code comprehensible by CNC machines. The aluminum sheet, securely clamped onto the machine's worktable, becomes the canvas for a high-speed rotating blade, the cutting tool. The tool meticulously follows the paths specified by the digital code, ensuring each cut is executed with unparalleled precision and accuracy.

The embrace of CNC cutting technology brings forth a plethora of benefits, positioning it as the pinnacle of precision in the manufacturing realm. Foremost among these advantages is the unmatched precision and accuracy that CNC machines offer. The ability to cut aluminum sheets with microscopic accuracy guarantees a perfect fit every time, elevating the quality of the end product. Efficiency takes center stage as CNC cutting streamlines production times, minimizing material waste and optimizing resource utilization. The automation of the cutting process translates into consistent, repeatable cuts, culminating in superior quality products that meet stringent standards.

The versatility of CNC cutting aluminum sheets finds its expression in a multitude of industries, each reaping the benefits of this cutting-edge technology. In the aerospace industry, CNC cutting contributes to the creation of lightweight and durable components vital for aircraft and spacecraft. Automotive manufacturers leverage CNC cutting to produce parts and panels characterized by tight tolerances and intricate shapes. The construction industry witnesses the fabrication of architectural elements like facades and cladding, showcasing the adaptability of CNC cutting. Meanwhile, in the electronics sector, CNC cutting carves out precise components that form the backbone of electronic devices, reflecting the technology's indispensable role in modern manufacturing.

Selecting the right CNC machine for cutting aluminum sheets involves a careful consideration of various factors. The size and thickness of the aluminum sheets are paramount, ensuring the chosen machine can accommodate the specific requirements of the project. Cutting speed and accuracy play pivotal roles, and the type of cutting tools employed must align with the desired precision levels. Manufacturers seek machines that offer a perfect balance of precision, accuracy, and cutting speed to maximize efficiency and elevate the overall productivity of the process.

In conclusion, the realm of CNC cutting aluminum sheets stands as a testament to the marriage of precision and technology in modern manufacturing. Unveiling the working principle, understanding its benefits, and exploring its diverse applications across industries underscore the transformative impact of CNC cutting. As manufacturers navigate the maze of choosing the right CNC machine, the promise of higher productivity, enhanced quality, and versatile solutions beckons, ensuring that CNC cutting remains at the forefront of the manufacturing revolution.

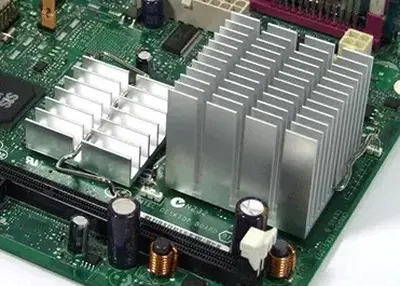

Heat Sinks: What They Are, How They Work, and How to Design ThemDecember 8, 2023Have you ever wondered how your laptop, smartphone, or gaming console can run so fast without overheating? The answer is heat sinks. Heat sinks are devices that help to cool down electronic components by transferring heat away from them. They are essential for ensuring the reliability and performance of many modern devices.view

Heat Sinks: What They Are, How They Work, and How to Design ThemDecember 8, 2023Have you ever wondered how your laptop, smartphone, or gaming console can run so fast without overheating? The answer is heat sinks. Heat sinks are devices that help to cool down electronic components by transferring heat away from them. They are essential for ensuring the reliability and performance of many modern devices.view Rapid Prototyping for Every Phase of Product DevelopmentOctober 11, 2023Time to market is critical to your competitive advantage. However, forgoing prototyping is a big risk that can cost you production costs, lost revenue, and your reputation if your product doesn't...view

Rapid Prototyping for Every Phase of Product DevelopmentOctober 11, 2023Time to market is critical to your competitive advantage. However, forgoing prototyping is a big risk that can cost you production costs, lost revenue, and your reputation if your product doesn't...view Types of Screws: A Comprehensive GuideSeptember 28, 2023Are you tired of struggling with mismatched screws or wondering which type is best for your project? Look no further! In this extensive guide, I will take you on a journey through the fascinating world of screws, from the basics to specialized types.view

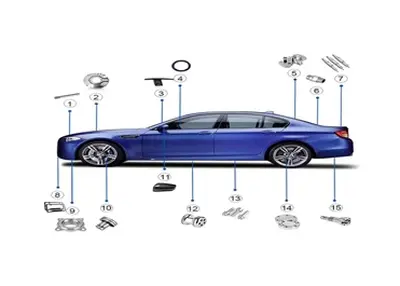

Types of Screws: A Comprehensive GuideSeptember 28, 2023Are you tired of struggling with mismatched screws or wondering which type is best for your project? Look no further! In this extensive guide, I will take you on a journey through the fascinating world of screws, from the basics to specialized types.view The Precision of CNC Automotive Parts in Gear SystemsJanuary 5, 2024In the world of automotive manufacturing, precision and reliability are crucial for the smooth operation of gear systems. As technology advances, the demand for precision components in the automotive ...view

The Precision of CNC Automotive Parts in Gear SystemsJanuary 5, 2024In the world of automotive manufacturing, precision and reliability are crucial for the smooth operation of gear systems. As technology advances, the demand for precision components in the automotive ...view Coordinate Measuring Machines: Products with High Accuracy in Measurement ResultsDecember 1, 2023Coordinate measurement in the coaxiality detection is often encountered in our measurement work, with the three coordinates for coaxiality detection is not only intuitive and convenient, three yuan, 2.5 times the yuan and the three coordinates of the measurement results of high precision, and good repeatability.view

Coordinate Measuring Machines: Products with High Accuracy in Measurement ResultsDecember 1, 2023Coordinate measurement in the coaxiality detection is often encountered in our measurement work, with the three coordinates for coaxiality detection is not only intuitive and convenient, three yuan, 2.5 times the yuan and the three coordinates of the measurement results of high precision, and good repeatability.view Protect, Enhance, Beautify: The Versatility of Blackening Surface TreatmentsDecember 4, 2023Surface treatments play a vital role in maintaining and enhancing the durability and appearance of various materials. Whether it is for aesthetic purposes, rust prevention, or to improve wear resistan...view

Protect, Enhance, Beautify: The Versatility of Blackening Surface TreatmentsDecember 4, 2023Surface treatments play a vital role in maintaining and enhancing the durability and appearance of various materials. Whether it is for aesthetic purposes, rust prevention, or to improve wear resistan...view

EN

EN

ru

ru