The aerospace industry has always been one of the pinnacles of technology and engineering, and it relies on precision-manufactured aerospace parts to ensure highly reliable and safe aviation and space systems. The manufacture of these parts involves challenges of material selection, high precision processes, and complex engineering requirements. In this article, we will explore the knowledge of various aspects of aerospace parts machining.

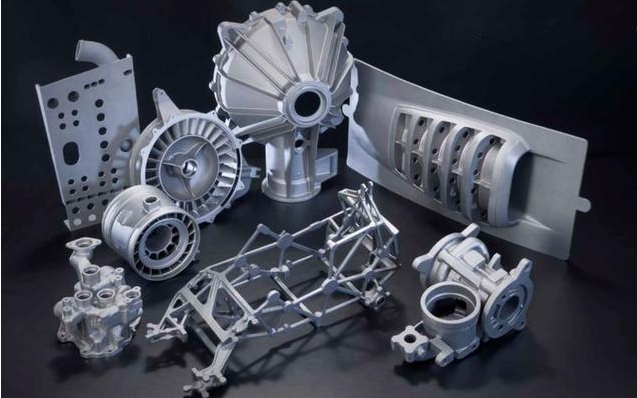

The manufacture of aerospace parts begins with specific material requirements. These parts typically need to have high strength, low density, high thermal stability, and corrosion resistance to cope with extreme operating conditions. Common aerospace materials include:

High-strength aluminum alloys are ideal for manufacturing aircraft structural parts due to their light weight, corrosion resistance, and ease of machining. For example, 7075 aluminum alloy is widely used in the manufacture of aerospace parts.

Titanium alloy has excellent strength to weight ratio and is widely used in aircraft engine parts, fuselage components and screws etc.

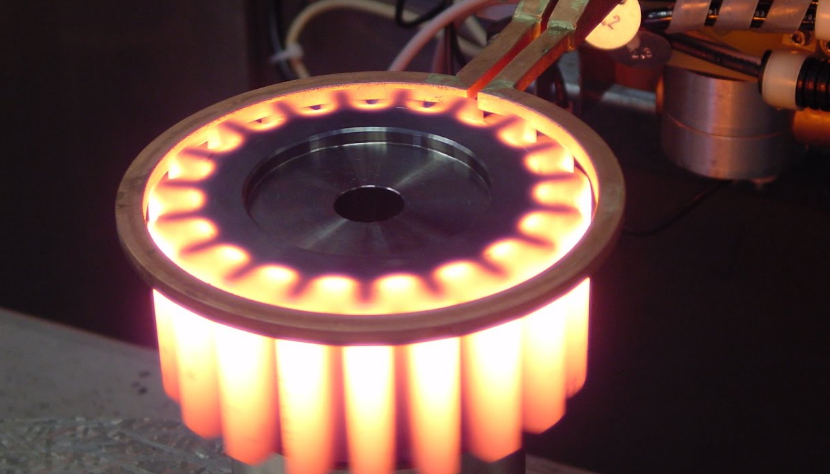

High-temperature alloys maintain strength and stability at high temperatures and are used in engine nozzles, turbine blades and other high-temperature parts.

Carbon fiber composites are excellent in reducing structural weight, increasing strength and reducing corrosion, and are commonly used to make shells for aerospace parts and spacecraft components.

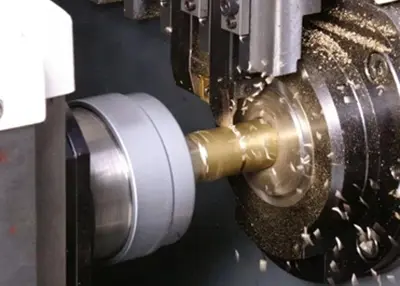

The manufacture of aerospace parts requires highly sophisticated part machining processes to ensure performance and reliability. For example, CNC machine tools; CNC machine tools are the core tools for machining aerospace parts. They are capable of performing CNC milling, CNC turning, drilling and other operations with high precision control. Secondly there are heat treatment, welding and riveting, surface quality these all directly affect the aerospace parts hardness, strength, wear resistance, high load resistance, high temperature resistance. At the same time in the axial precision, thermal stability and other aspects need to be extremely high requirements.

Aerospace parts processing is full of challenges, mainly in the following aspects:

Aerospace parts usually have complex geometries and require high precision machining to meet design requirements.

Machining of high temperature alloys is difficult and requires special tools and processes to handle these hard materials.

Spacecraft parts are usually very large and require large CNC machine tools and special machining equipment.

The aerospace industry has very high requirements for part quality and requires strict quality control and inspection to ensure that each part meets standards. Precision and reliability are key in aerospace parts machining. A deep understanding and fine control of materials, processes, precision and machining difficulties are the key to manufacturing high quality aerospace parts.

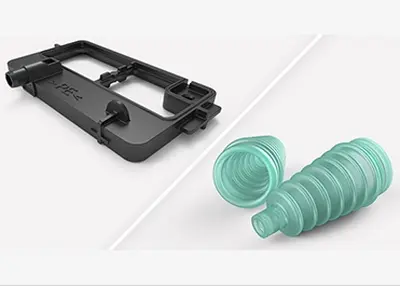

DESIGN TIP: Thermoplastics and Thermosets in ComparisonOctober 18, 2023There are two main categories of plastic materials: thermoplastics and thermosets, which differ in their behavior under heat. In this design tip, we present a few considerations to keep in mind when using these materials.view

DESIGN TIP: Thermoplastics and Thermosets in ComparisonOctober 18, 2023There are two main categories of plastic materials: thermoplastics and thermosets, which differ in their behavior under heat. In this design tip, we present a few considerations to keep in mind when using these materials.view 10 Common Metal Materials for CNC Machining & Typical UsesApril 12, 2024Here are 10 common metal materials for CNC machining and their typical uses. Read on and get useful suggestions on how to select suitable metal materials for your project.view

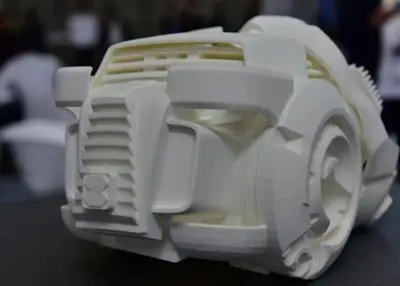

10 Common Metal Materials for CNC Machining & Typical UsesApril 12, 2024Here are 10 common metal materials for CNC machining and their typical uses. Read on and get useful suggestions on how to select suitable metal materials for your project.view The Ultimate 3D Printing Guide: Types of 3D Printers, Materials & MoreApril 17, 2024Here is an ultimate guide to 3D printing technology, including types of 3D printers, materials, and more. Read on and choose the right one for your project.view

The Ultimate 3D Printing Guide: Types of 3D Printers, Materials & MoreApril 17, 2024Here is an ultimate guide to 3D printing technology, including types of 3D printers, materials, and more. Read on and choose the right one for your project.view What is CNC Turning: Process, Operations, AdvantagesApril 11, 2024Here is a range of topics about CNC turning, including process, operations and advantages. Then, decide whether it is the best operation for your project.view

What is CNC Turning: Process, Operations, AdvantagesApril 11, 2024Here is a range of topics about CNC turning, including process, operations and advantages. Then, decide whether it is the best operation for your project.view Exploring the World of Cold Machined Parts: Unveiling the Secrets of Performance and ManufacturingNovember 14, 2023In the realm of precision engineering, the term cold machined parts sparks curiosity and a quest for knowledge. As we delve into this intricate domain, my aim is to unravel the mysteries surrounding these components, providing you with a comprehensive understanding of their technology, applications, and performance.view

Exploring the World of Cold Machined Parts: Unveiling the Secrets of Performance and ManufacturingNovember 14, 2023In the realm of precision engineering, the term cold machined parts sparks curiosity and a quest for knowledge. As we delve into this intricate domain, my aim is to unravel the mysteries surrounding these components, providing you with a comprehensive understanding of their technology, applications, and performance.view The Basics of Engineering Drawing and Tips for NewcomersApril 7, 2024The article gives some useful tips on how to make engineering drawings easily to help you better communicate your ideas clearly.view

The Basics of Engineering Drawing and Tips for NewcomersApril 7, 2024The article gives some useful tips on how to make engineering drawings easily to help you better communicate your ideas clearly.view

EN

EN

ru

ru