Machining is a widely used manufacturing process and is one of the common machining methods used in the manufacturing industry for making different types of parts. Different types of parts require different processes to machine them to meet their specific requirements. This includes many different part types and machining processes. The following are some common types of machined parts and the machining processes commonly used for each type:

Shaft parts are usually cylindrical and are used for connection and rotation. Common shaft parts include bearing shafts, rotating shafts, and transmission shafts. Machining processes include turning, grinding and threading. Turning is the most common method whereby the workpiece is rotated and material is removed with a tool to obtain the desired size and shape. For bearing shafts where high precision is required, grinding may also be performed. In addition, shaft parts may require drilling, reaming, tapping and other machining processes.

Gear parts include various types of gears, such as cylindrical gears and bevel gears, which are usually round. The machining of gears usually includes machining processes such as milling, gear cutting, hobbing, gear inserting, shaving, grinding and heat treatment. Milling is used to create the basic shape of the gear while gear cutting is used to cut the teeth of the gear. Grinding is used to improve the accuracy and surface quality of gears. Heat treatment is usually used to enhance the hardness and wear resistance of gears.

Bolts and nuts are common components used to join parts. They are usually round or cylindrical in shape and are subjected to turning, cutting and threading. Turning is used to create the body shape of the bolt and nut, while cutting is used to cut the threads. Threading usually involves single point thread cutting and thread rolling.

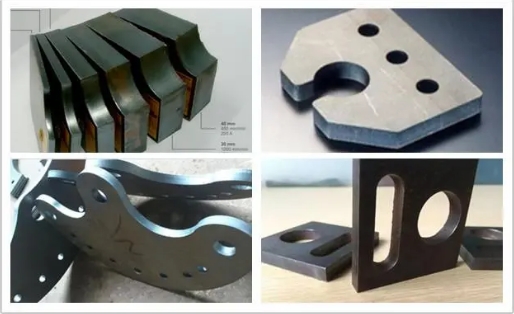

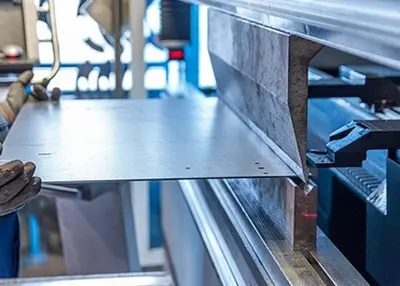

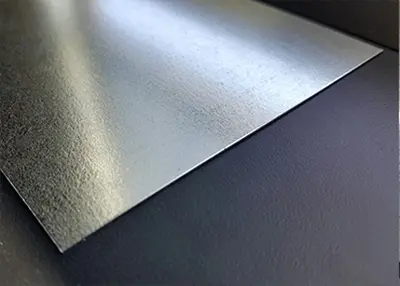

Plate-type parts include various types of flat plates, thin plates, sheet metal, chassis, brackets, etc. Plate type parts are usually flat or curved. Machining processes include plane grinding, milling, shearing, bending, stamping, welding and riveting. Shearing is used to cut the plate into the desired shape, bending is used to bend the plate, stamping is used to create holes and concave or curved sections in the plate, and welding and riveting are used to join different plate parts together to assemble a whole.

Sleeve parts usually include bearings, plain bearings, flanges, etc. These parts usually require machining processes such as internal turning, internal grinding, external grinding, etc. to obtain accurate diameter and roundness. In addition, sleeve parts may require machining processes such as drilling, reaming, and tapping.

Block-type parts include various types of squares, rectangular blocks, cylinders, and so on. These parts usually require machining processes such as surface grinding, milling, etc. to obtain accurate flatness and contour. In addition, block type parts may require drilling, tapping and other machining processes.

Casting parts are usually complex three-dimensional shapes, such as engine blocks, pump housings and so on. Machining processes include casting, grinding, turning and heat treatment. Casting is the primary method of manufacturing cast parts, by pouring molten metal into a mold to create the shape of the part. Grinding, turning and heat treatment are then used to improve surface quality and accuracy.

Case-type parts include various types of machine housings, machine tool beds, and so on. These parts usually require surface

Grinding, milling and other machining processes to obtain accurate flatness and contour. In addition, box parts may require drilling, tapping and other machining processes.

Electronic parts are usually small, such as circuit boards and connectors. Machining processes include cutting, stamping, welding and plating. Cutting and stamping are used to create shapes and holes for circuit boards, soldering is used to connect electronic components, and plating is used to protect and improve surface properties.

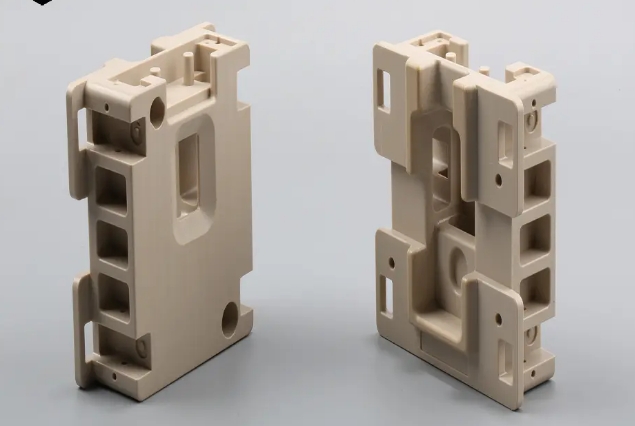

Plastic-based parts are commonly used in a variety of applications such as injection molding, extrusion molding, and compression molding. Injection molding creates parts by injecting melted plastic into a mold, extrusion molding creates parts by extruding plastic into a desired shape, and compression molding creates parts by heating plastic and forming it in a mold.

In addition to these common types of machined parts, there are many other types of parts, such as shaped parts and free-form parts. For each type of part, different machining processes can be selected to achieve the required shape and size accuracy and surface quality. For example, for complex shaped parts, CNC machine tools can be used for multi-axis machining; for free-form surfaces, coordinate measuring machines can be used for measurement and processing.

Different types of parts require different machining processes to meet their specific requirements. Selecting the appropriate process and machining method is critical to ensuring the quality, accuracy and performance of the part. In actual manufacturing, the appropriate machining process is usually selected based on the shape, material and requirements of the part to achieve the best machining results.

Machining is an integral part of manufacturing and is used to create a variety of different types of parts. Each part type requires a specific machining process to meet its requirements, whether it's shaft parts, gear parts, bolts and nuts, plate parts, bushings, blocks, castings, cases, electronics or plastics, there's a suitable machining method for it.

When it comes to machining, Richconn is a precision manufacturing company with the experience and state-of-the-art equipment to provide high-quality precision CNC machining services. No matter what type of part you need to manufacture, Richconn can select the right process for your requirements to ensure the quality, accuracy and performance of your part. Whether it's a small electronic part or a complex cast part, Richconn can meet your needs with a customized solution.

If you are in need of precision machining services or more information about machining processes, please feel free to contact Richconn and they will be happy to provide you with the professional support you need to ensure the successful completion of your project. Machining is a complex and sophisticated technology that can only be performed by an experienced company with state-of-the-art equipment, and Richconn is the partner you can trust.

CNC POR: Demystifying the Key Technology in CNC MachiningNovember 2, 2023In the world of precision engineering and manufacturing, CNC technology plays a pivotal role. Among the various CNC techniques, CNC POR stands out as a critical component, offering unmatched precision, efficiency, and versatility.view

CNC POR: Demystifying the Key Technology in CNC MachiningNovember 2, 2023In the world of precision engineering and manufacturing, CNC technology plays a pivotal role. Among the various CNC techniques, CNC POR stands out as a critical component, offering unmatched precision, efficiency, and versatility.view Sheet Metal Thickness Conversion Chart: Galvanized Steel, Stainless Steel, AluminumDecember 5, 2023In sheet metal work, the term "gauge" is frequently employed to specify thickness. Gauges are the units used to indicate the thickness of a metal sheet.view

Sheet Metal Thickness Conversion Chart: Galvanized Steel, Stainless Steel, AluminumDecember 5, 2023In sheet metal work, the term "gauge" is frequently employed to specify thickness. Gauges are the units used to indicate the thickness of a metal sheet.view Beyond Aesthetics: The Practical Benefits of Blackening Surface TreatmentDecember 4, 2023When it comes to surface treatments for various metal components, one often thinks about aesthetics and corrosion resistance as the primary goals. However, there is another important surface treatment...view

Beyond Aesthetics: The Practical Benefits of Blackening Surface TreatmentDecember 4, 2023When it comes to surface treatments for various metal components, one often thinks about aesthetics and corrosion resistance as the primary goals. However, there is another important surface treatment...view 6 Benefits of Partnering With a Trusted CNC CompanySeptember 13, 2023Why choose a CNC company to partner with? Let’s explore the advantages of partnering with a CNC company for precision machining and top-quality parts.view

6 Benefits of Partnering With a Trusted CNC CompanySeptember 13, 2023Why choose a CNC company to partner with? Let’s explore the advantages of partnering with a CNC company for precision machining and top-quality parts.view How Much Do 3D Prints Cost: An In-Depth Guide to ExpensesAugust 15, 20233D printing has revolutionized manufacturing and design, allowing individuals and businesses to create intricate and customized objects with unprecedented ease. However, one common question that arise...view

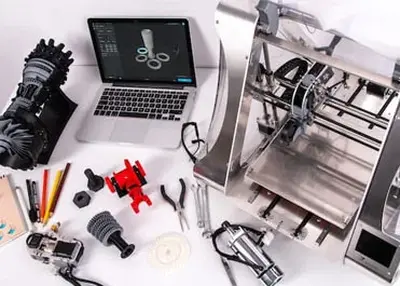

How Much Do 3D Prints Cost: An In-Depth Guide to ExpensesAugust 15, 20233D printing has revolutionized manufacturing and design, allowing individuals and businesses to create intricate and customized objects with unprecedented ease. However, one common question that arise...view Richconn: Secondary ServicesOctober 12, 2023Many of our customers order parts that come ready-made from plastic injection molding or CNC machining. Many others, however, want or need "secondary machining" of the parts so produced.view

Richconn: Secondary ServicesOctober 12, 2023Many of our customers order parts that come ready-made from plastic injection molding or CNC machining. Many others, however, want or need "secondary machining" of the parts so produced.view

EN

EN

ru

ru